Polyurethane plastic runway adhesive and preparation method thereof

A technology of plastic track and adhesive is applied in the field of chemical adhesive to achieve the effect of improving strength and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

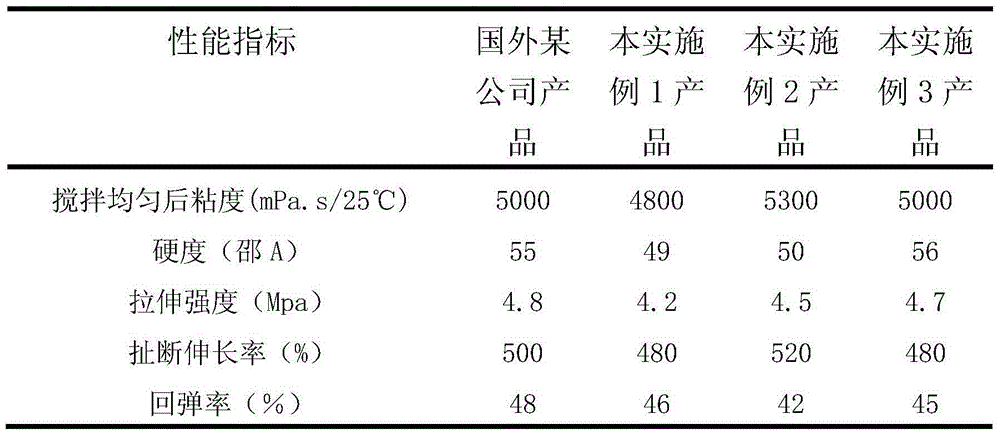

Examples

Embodiment 1

[0020] Preparation of environment-friendly two-component polyurethane plastic runway adhesive:

[0021] (1) Preparation of component A;

[0022] In the reaction equipment equipped with stirrer, thermometer and reflux condenser, add 146.14g of adipic acid, 68.32g of ethylene glycol, 0.008g of catalyst antimony acetate, and 0.36g of heat stabilizer triphenyl phosphite to start stirring, and the temperature rises To 120 ~ 130 ℃, the adipic acid is completely dissolved. Nitrogen gas is kept at reflux for 1 hour to make the dibasic acid interact with the dibasic alcohol to form a small molecule polyester. The temperature is raised to 150°C for dehydration, and the temperature at the top of the fractionation head is controlled to 100-102°C. After the water is discharged, the temperature in the system is gradually raised to 240°C within 3-4 hours. The temperature rise is slow at first and then fast. Raise the temperature of the material to 240°C and keep it warm for 1 hour, start v...

Embodiment 2

[0028] Preparation of environment-friendly two-component polyurethane plastic runway adhesive:

[0029] (1) Preparation of component A;

[0030] In the reaction equipment that stirrer, thermometer, reflux condenser are housed, add adipic acid 146.14g, ethylene glycol 72.16g, catalyst antimony acetate 0.009g, thermal stabilizer triphenyl phosphite 0.38g start to stir, temperature rises To 120 ~ 130 ℃, the adipic acid is completely dissolved. Nitrogen gas is kept at reflux for 1 hour to make the dibasic acid interact with the dibasic alcohol to form a small molecule polyester. The temperature is raised to 150°C for dehydration, and the temperature at the top of the fractionation head is controlled to 100-102°C. After the water is discharged, the temperature in the system is gradually raised to 240°C within 3-4 hours, and the temperature rise is slow at first and then fast. Raise the temperature of the material to 240°C and keep it warm for 1 hour, start vacuum dehydration, let...

Embodiment 3

[0036] Preparation of environment-friendly two-component polyurethane plastic runway adhesive:

[0037] (1) Preparation of component A;

[0038] In the reaction equipment equipped with stirrer, thermometer and reflux condenser, add 73.07g of adipic acid, 94.11g of azelaic acid, 68.32g of ethylene glycol, 0.01g of catalyst antimony acetate, and 0.54g of heat stabilizer triphenyl phosphite g Start stirring, and the temperature rises to 120-130°C to completely dissolve the adipic acid. Nitrogen gas is kept at reflux for 1 hour to make the dibasic acid interact with the dibasic alcohol to form a small molecule polyester. The temperature is raised to 150°C for dehydration, and the temperature at the top of the fractionation head is controlled to 100-102°C. After the water is discharged, the temperature in the system is gradually raised to 240°C within 3-4 hours. The temperature rise is slow at first and then fast. Raise the temperature of the material to 240°C and keep it warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com