Establishment method and application of goethite method iron precipitation process interface reaction model

A process interface and method establishment technology, applied in the direction of process efficiency improvement, etc., can solve problems such as harsh conditions, difficult research and analysis, and no consideration of mesoscale interface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

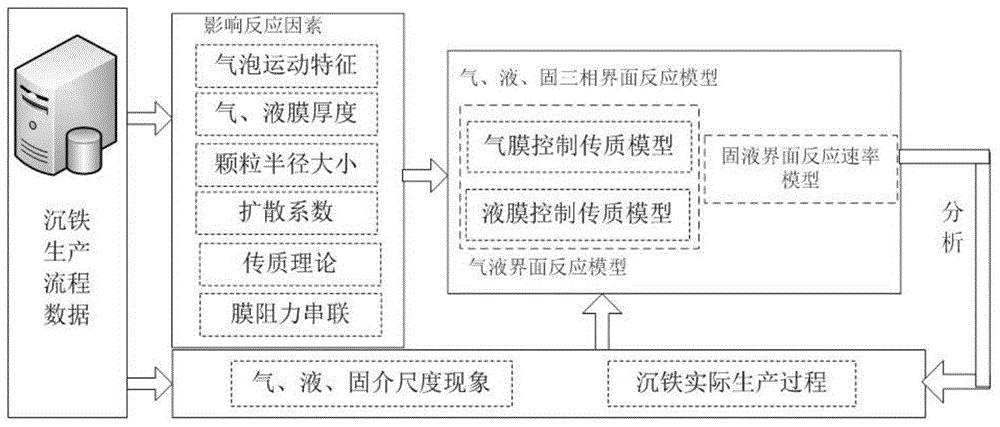

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

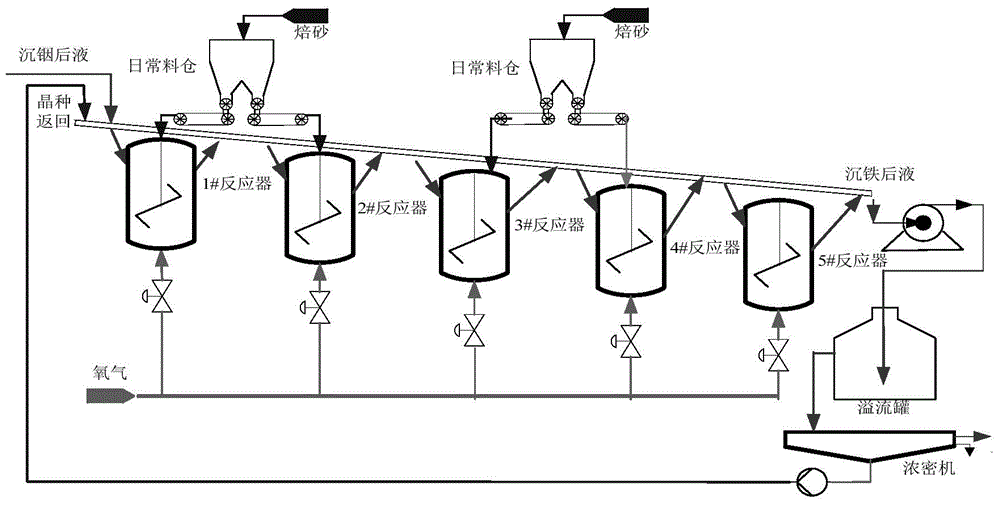

[0124] A method for establishing an interface reaction model of a goethite iron precipitation process mainly includes the following steps:

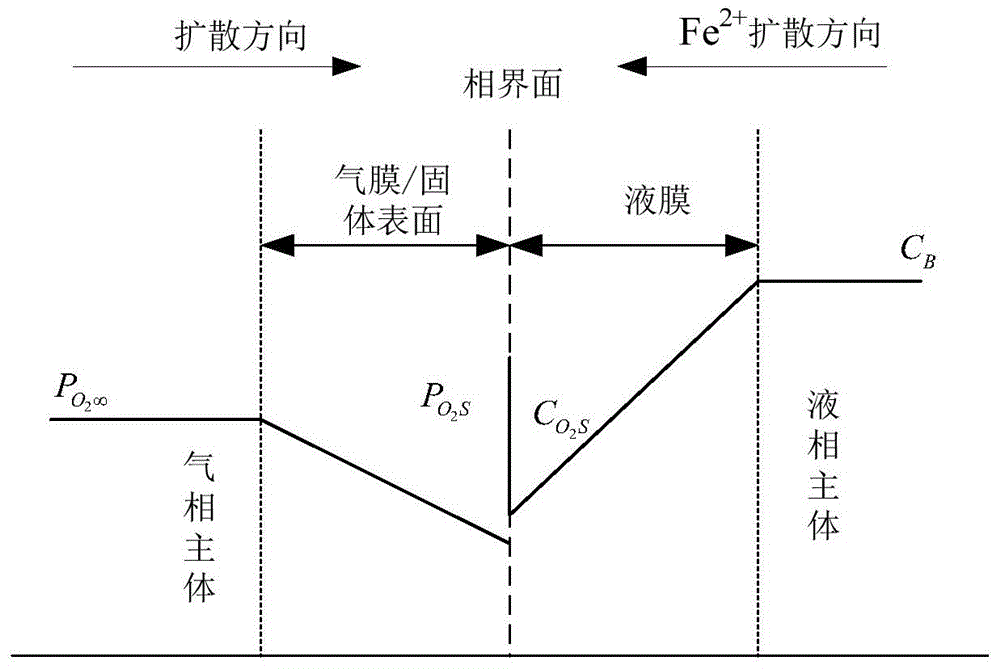

[0125] (1) According to the process mechanism of the goethite iron precipitation process, combined with the relationship between the mass transfer rate and the interface gas-liquid reaction rate, the following formula (I) gas film control mass transfer model is established from the perspective of mass transfer driving force, for Analyze the gas film thickness, gas diffusion coefficient and bubble radius to control the chemical reaction rate in this stage.

[0126] d c F e 2 + ...

Embodiment 2

[0147] A method for controlling the internal three-phase interface chemical reaction rate of a goethite process iron-precipitation process reactor, comprising establishing a goethite process iron-precipitation process interface reaction model according to the method in Example 1, using the model to realize the control of the chemical reaction rate and Precise control of the reaction process. Specifically, the control of the reaction process can be carried out in the following ways:

[0148] (1) The built model is numerically simulated to obtain the concentration curves of ferrous ions in the two control stages, so as to obtain the chemical reaction rate and mass transfer coefficient D1, D2, and the initial value of the bubble radius a 0 , the relationship between liquid film thickness L. The reaction rate increases with the increase of mass transfer coefficient, and slows down with the increase of bubble radius and liquid film thickness. The values of some control factors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com