Sodium alginate-cuttlebone-hairyvein agrimony extract product blend fiber, and preparation method thereof

A technology of sodium alginate and blended fibers, which is applied in the field of polymer chemical materials, can solve the problems of lack of efficient hemostasis, dampness and sores, and achieve safety, biodegradability, good liquid absorption and biological activity, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

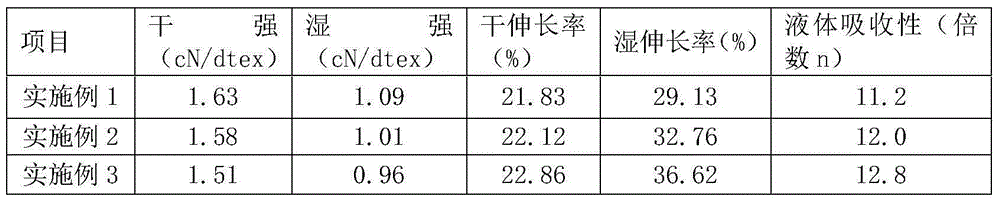

Examples

Embodiment 1

[0021] The sodium alginate octopus Agrimony extract blend fiber in this example includes sodium alginate, octopus and Agrimony extract, the weight percentage of the above components is: sodium alginate 70%, octopus 20% , Agrimony extract 10%;

[0022] The preparation method of the sodium alginate seaweed octopus Agrimony extract blend fiber of the present embodiment comprises the following steps:

[0023] (1) Sodium alginate (food grade) was dissolved in deionized water at 50°C and stirred to dissolve, the addition amount was 50g / 1000ml, and a sodium alginate spinning solution with a mass percentage of 5% was obtained;

[0024] (2) Grinding sea octopus into ultra-fine powder with a particle size of 3 microns or less; adding the sea octopus superfine powder into water at room temperature, the addition amount is 300g / 1000ml, and adding it to the mass of sea octopus A dispersant with a percentage of 1.5%; fully stirred to make a superfine powder slurry of squid octopus;

[0025...

Embodiment 2

[0029] The sodium alginate octopus Agrimony extract blend fiber in this example includes sodium alginate, octopus Agrimony and Agrimony extract, the weight percentage of the above components is: sodium alginate 76%, octopus Agrimony 16% %, Agrimony extract 8%;

[0030] The preparation method of the sodium alginate seaweed octopus Agrimony extract blend fiber of the present embodiment comprises the following steps:

[0031] (1) Sodium alginate (food grade) was dissolved in deionized water at 40°C and stirred, and the addition amount was 40g / 1000ml to obtain a sodium alginate spinning solution with a mass percentage of 4%;

[0032] (2) Grinding sea octopus into superfine powder with a particle size of less than 3 microns; adding the sea octopus ultrafine powder into water at room temperature, the addition amount is 250g / 1000ml, and adding the sea octopus mass Percentage of 1% dispersant; fully stirred to make sea octopus superfine powder slurry;

[0033] (3) Add the powdered A...

Embodiment 3

[0037]The sodium alginate octopus Agrimony extract blend fiber in this example includes sodium alginate, octopus Agrimony and Agrimony extract, the weight percentage of the above components is: sodium alginate 82%, octopus Agrimony 12% %, Agrimony extract 6%;

[0038] The preparation method of the sodium alginate seaweed octopus Agrimony extract blend fiber of the present embodiment comprises the following steps:

[0039] (1) Sodium alginate (food grade) was dissolved in deionized water at 30°C and stirred, and the addition amount was 30g / 1000ml to obtain a sodium alginate spinning solution with a mass percentage of 3%;

[0040] (2) Grinding sea octopus into ultra-fine powder with a particle size of 3 microns or less; adding the sea octopus ultrafine powder into water at room temperature, the amount of addition is 200g / 1000ml, and adding the mass of sea octopus Percentage of 0.5% dispersant; fully stirred to make sea octopus superfine powder slurry;

[0041] (3) Add the powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com