Method for preparing Fe2O3/V2O5 composite fibers with electrostatic spinning method

A technology of electrospinning and composite fibers, which is applied in the field of Fe2O3/V2O5 composite fibers prepared by electrospinning, can solve the problems of restricting the commercialization process of photocatalysis technology, affecting the photocatalysis effect, difficult to separate and recycle, etc. Visible light catalytic performance, improved photocatalytic degradation efficiency, and fast preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

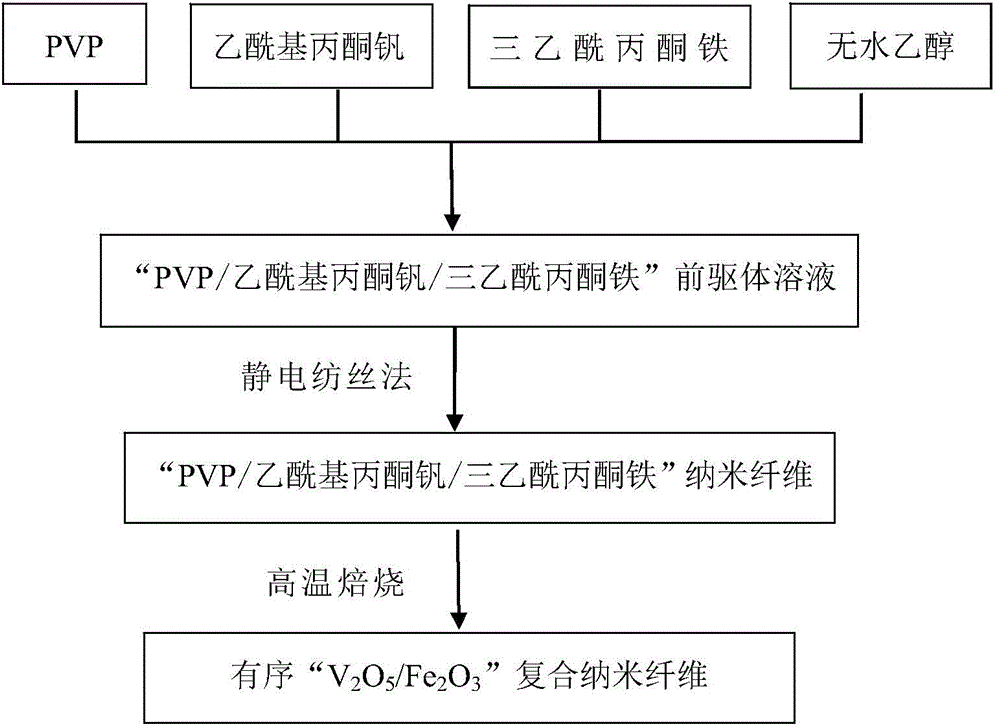

[0026] The preparation process is as figure 1 shown.

[0027] (1) Preparation of spinning solution: take 0.10g vanadium acetylacetonate and 0.10g iron triacetylacetonate with an electronic balance, dissolve them in 8.05ml absolute ethanol solution, and keep stirring until the solute is completely dissolved; Add 0.6g polyvinylpyrrolidone (PVP) in the solution, continue to stir, until PVP dissolves completely, obtain spinning solution;

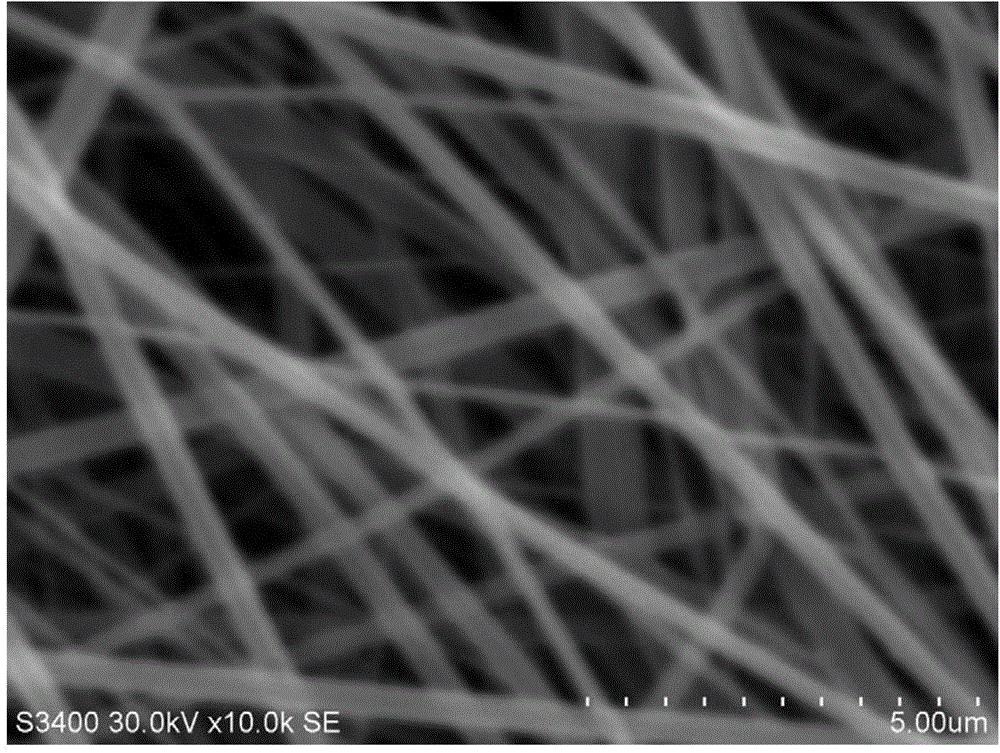

[0028] (2) Electrospinning: use heating and dehumidification methods, control the temperature to 30-40 ° C, and carry out electrospinning under an environment with a humidity ≤ 35%, and add the spinning solution prepared in step (1) to the In the syringe, the syringe needle is connected to the positive pole of the power supply, the aluminum foil is used as the receiving device, and the negative pole of the power supply is connected. The spinning distance is 13cm, the voltage is 16kV, and the injection speed of spinning solution is 0.01ml / min. A...

Embodiment 2

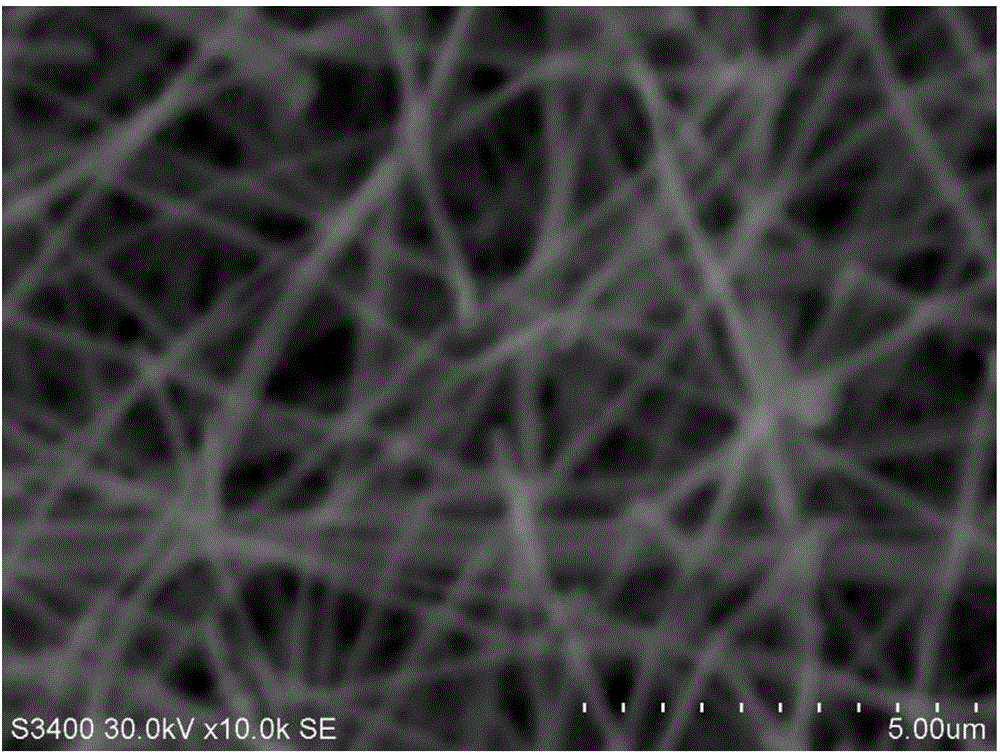

[0033] (1) Preparation of spinning solution: take 0.20g vanadium acetylacetonate and 0.10g iron triacetylacetonate with an electronic balance, dissolve them in 15ml absolute ethanol solution, and keep stirring until the solute is completely dissolved; Add 1.0g polyvinylpyrrolidone (PVP) in, keep stirring, until PVP dissolves completely, obtain spinning solution;

[0034] (2) Electrospinning: adopt methods such as heating and dehumidification, control the temperature to be about 40 ℃, carry out electrospinning under the environment of about 30% humidity, add the spinning solution prepared in step (1) to the In the syringe, the syringe needle is connected to the positive pole of the power supply, the aluminum foil is used as the receiving device, and the negative pole of the power supply is connected. The spinning distance is 15cm, the voltage is 20kV, and the injection speed of the spinning solution is 0.02ml / min. After spinning for a period of time, nano Fiber membrane;

[00...

Embodiment 3

[0038] (1) Preparation of spinning solution: take 0.10g vanadium acetylacetonate and 0.25g iron triacetylacetonate with an electronic balance, dissolve them in 25ml absolute ethanol solution, and keep stirring until the solute is completely dissolved; Add 0.8g polyvinylpyrrolidone (PVP) in, keep stirring, until PVP dissolves completely, obtain spinning solution;

[0039] (2) Electrospinning: adopt methods such as heating up and dehumidification, control the temperature at 30-40°C, and carry out electrospinning under an environment with a humidity of about 30%, and add the spinning solution prepared in step (1) to the In the needle syringe, the needle of the syringe is connected to the positive pole of the power supply, and the aluminum foil is used as the receiving device, connected to the negative pole of the power supply, the spinning distance is 10cm, the voltage is 16kV, the injection speed of the spinning solution is 0.02ml / min, and spinning for a period of time to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com