A light, breathable, UV-resistant fabric

An anti-ultraviolet, light and thin technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of thick, airtight, moisture-permeable, and poor comfort in anti-ultraviolet fabrics, achieve excellent anti-ultraviolet performance, and reduce hairiness. Fluffy, hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

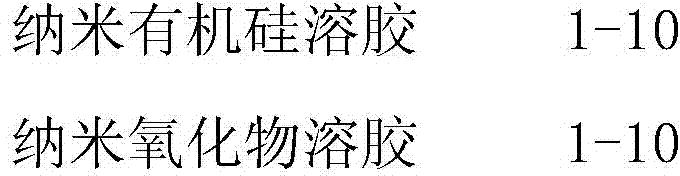

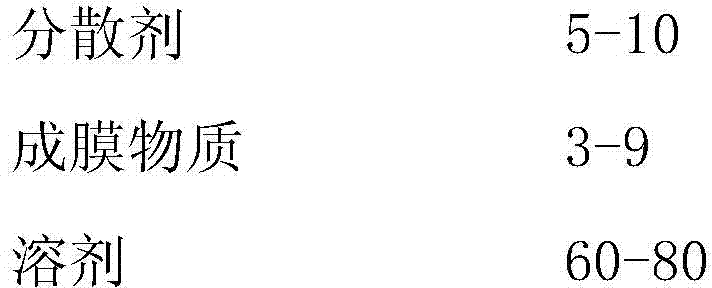

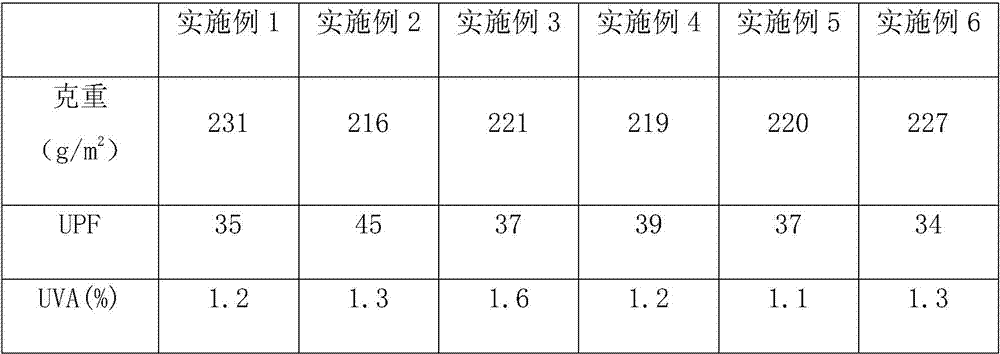

[0026] A novel light, breathable and anti-ultraviolet fabric comprises a high-count, high-density ultra-thin ramie fabric and a transparent nano-modified organic-inorganic composite coating. The ramie fabric treated with biological enzymes is modified by plasma, then dipped into the nano-modified organic-inorganic composite coating, dipping and rolling, to obtain a light, breathable and anti-ultraviolet fabric.

[0027] Wherein the components and dosage in the nano-modified organic-inorganic composite coating, by weight, include: 1 part of 20-50nm nano-organosilicon sol with a content of 15%, 10 parts with a volume ratio of 1:0.5 A mixture of nano-alumina sol and 150nm nano-silica sol, 10 parts of polysiloxane polymer dispersant, 3 parts of diethylene glycol ether film-forming substance and 60 parts of ethanol solvent.

Embodiment 2

[0029] A novel light, breathable and anti-ultraviolet fabric comprises a high-count, high-density ultra-thin ramie fabric and a transparent nano-modified organic-inorganic composite coating. The ramie fabric treated with biological enzymes is modified by plasma, then dipped into the nano-modified organic-inorganic composite coating, dipping and rolling, to obtain a light, breathable and anti-ultraviolet fabric.

[0030] Wherein the components and dosage in the nano-modified organic-inorganic composite coating, by weight, include: 10 parts of 20-50nm nano-organosilicon sol with a content of 5%, 1 part with a volume ratio of 1:1.5 A mixture of nano-alumina sol and 150nm nano-silica sol, 5 parts of maleic anhydride polymer dispersant, 9 parts of ethylene glycol butyl ether film-forming substance and 80 parts of ethanol solvent.

Embodiment 3

[0032] A novel light, breathable and anti-ultraviolet fabric comprises a high-count, high-density ultra-thin ramie fabric and a transparent nano-modified organic-inorganic composite coating. The ramie fabric treated with biological enzymes is modified by plasma, then dipped into the nano-modified organic-inorganic composite coating, dipping and rolling, to obtain a light, breathable and anti-ultraviolet fabric.

[0033] Wherein the components and dosages in the nano-modified organic-inorganic composite coating, in parts by weight, include: 5 parts of 20-50nm nano-organosilicon sol with a content of 8%, 5 parts of nano-organic silica sol with a volume ratio of 1:0.7 A mixture of nano-alumina sol and 150nm nano-silica sol, 8 parts of maleic anhydride polymer dispersant, 6 parts of ethylene glycol butyl ether film-forming substance and 70 parts of ethanol solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com