Multilayer film

A laminated film and polarizing film technology, applied in the direction of layered products, synthetic resin layered products, instruments, etc., can solve the problems of polarizing film productivity, yield reduction, cost increase, tensile fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Examples of the liquid medium used in the preparation of the membrane-forming stock solution include water, dimethylsulfoxide, dimethylformamide, dimethylacetamide, N-methylpyrrolidone, ethylene glycol, glycerin, propylene glycol, Diethylene glycol, triethylene glycol, tetraethylene glycol, trimethylolpropane, ethylenediamine, diethylenetriamine, etc., one or two or more of these liquid media can be used. Among these, water is preferable from the viewpoint of a small burden on the environment and recyclability.

[0054] The volatile fraction of the film-forming stock solution (the content ratio of volatile components in the film-forming stock solution such as volatilization or evaporation during film-forming) varies depending on the film-forming method, film-forming conditions, etc., and is preferably 50 to 95% by mass , more preferably in the range of 55 to 90% by mass, and even more preferably in the range of 60 to 85% by mass. By setting the volatile fraction of the...

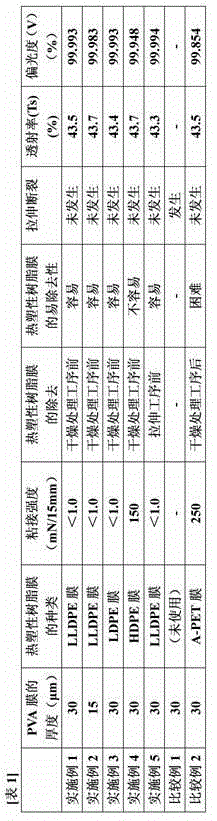

Embodiment 1

[0097] The strip PVA film (containing PVA, glycerin and surfactant that thickness is 30 μ m and width is 1m, the content of glycerol is 12 mass parts relative to PVA100 mass parts, the content of surfactant is 0.03 mass parts relative to PVA100 mass parts The PVA film.PVA is the saponification product of the homopolymer of vinyl acetate, and the polymerization degree of PVA is 2400, and the saponification degree of PVA is 99.9 mol%.) continuously roll out from its film roll. On the other hand, a long linear low-density polyethylene film (LLDPE film, manufactured by Tamapoli Co., Ltd., SE620N) having a thickness of 50 μm and a width of 1.2 m was continuously unwound from the film roll. Then, the two films rolled out are superimposed in the approximate mode of the centerline in the width direction (the bonding strength between the two films is less than 1.0mN / 15mm), and the swelling treatment, dyeing treatment and crosslinking treatment are sequentially and continuously implement...

Embodiment 2

[0103] Polarizing films were continuously produced in the same manner as in Example 1 except that the thickness of the PVA film was changed to 15 μm. It should be noted that the bonding strength between the two films in the laminated film is less than 1.0 mN / 15 mm.

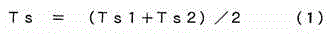

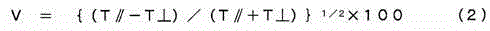

[0104] In the production of the above-mentioned polarizing film, curling was not observed at both ends in the width direction of the PVA film after passing through any of the water contact steps, and tensile fracture did not occur in the stretching step. In addition, removal of the thermoplastic resin film is extremely easy. The polarizing performance of the obtained polarizing film was measured as Ts=43.7(%) and V=99.983(%) according to the above method. The above results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com