Composite amino acid chelated calcium prepared by using oysters as raw materials

A compound amino acid and oyster technology, which is applied in food preparation, acid-containing food ingredients, functions of food ingredients, etc., can solve the problems of high heavy metal content, low utilization rate, low calcium content, etc., and achieve high biological potency , Biological potency manuscript, the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

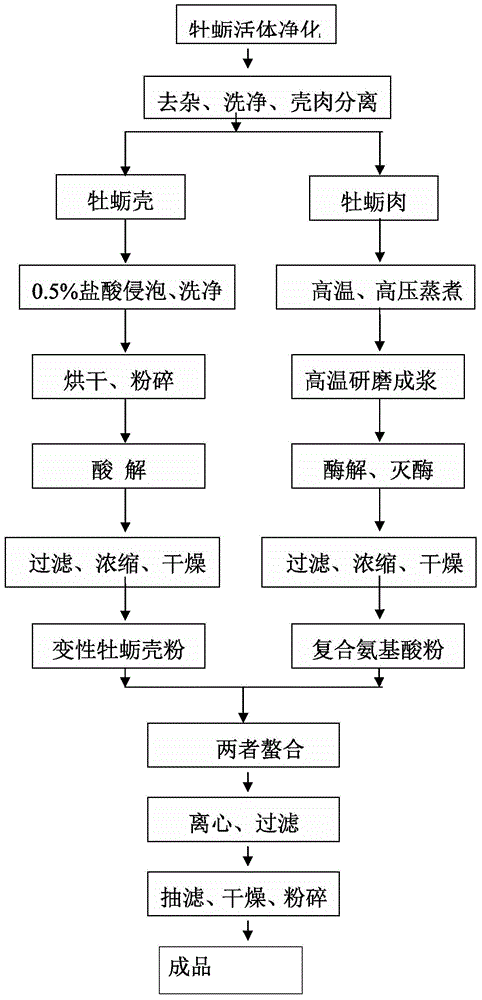

Image

Examples

Embodiment 1

[0027] (1) Soak 130 g of oyster shells in 0.5% hydrochloric acid solution for 1 hour, then scrub to remove adsorbates such as silt on the surface of the shells, dry at 100°C for 1 hour, and crush through a 100-mesh sieve to obtain 110 g of oyster shell powder. Weigh again 100g of the screened sample, add it to 175ml of 3mol / L hydrochloric acid, mix, act at a temperature of 110°C for 2 hours, filter, concentrate under reduced pressure, and spray dry to obtain 70g of denatured soluble calcium containing 28.08%. Oyster shell powder.

[0028] (2) Take 218g of oyster meat, wash it, cook it at high temperature, grind it into a slurry, add 1L of water to make an aqueous solution with a protein mass fraction of 2%, put it in a reactor, soak it in a water bath at 55°C for 30 minutes, and mix it according to the amount of enzyme and substrate protein. Add 11g of neutral protease at a ratio of 8000U / g, adjust the pH of the solution to 7.0 with phosphate buffer; put it in a constant tempe...

Embodiment 2

[0031] The present invention selects the first-generation calcium product calcium carbonate, the second-generation calcium product calcium lactate, and the calcium product compound amino acid chelated calcium of the present invention as calcium supplements, and the following comparative experiments have been carried out on animals:

[0032] Experiment 1: Effects of compound amino acid calcium on mouse coat, skin and internal organs.

[0033] Step 1: Select 40 healthy mice and randomly divide them into 4 groups, with 10 males and more than half males in each group. In addition to the same conventional feed, the three groups were fed with different calcium supplements for comparative experiments, and one group was only fed with feed for blank comparative experiments. The method of calcium supplement measurement is: different calcium supplements are converted into calcium element, that is, the mass of calcium element supplied per kilogram of animal weight per day (mg.kg -1 .d -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com