A folium perillae active ingredient containing beverage and a preparation method thereof

An active ingredient, the technology of perilla leaf, which is applied in the field of beverages containing the active ingredient of perilla leaf and its preparation, can solve the problems of complex production process of perilla beverage, long time required and long time, etc., so as to improve bioavailability , increase the active ingredient, and facilitate the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

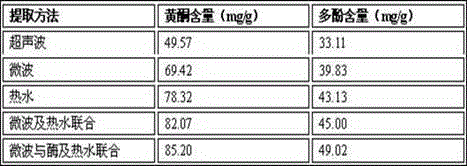

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Collect fresh perilla leaves, select and remove inedible parts, clean them, dry them until the moisture content of perilla leaves is less than 8%, and then crush them into powder with a universal grinder. Weigh dry perilla leaf powder, mix it with water at a weight ratio of 1:30, treat it at a microwave power of 200W to a temperature of 50°C, add cellulase for enzymatic hydrolysis (1600U / g of enzyme added) and keep soaking Extract for 40 minutes, filter, and put the filtrate in a clean container for later use; mix the filter residue and water at a mass ratio of 1:30, treat it at a microwave power of 200W to 90°C, extract for 30 minutes at a constant temperature, stop heating, and filter. The two filtrates were combined for later use.

[0015] Weigh 60kg of white granulated sugar, 18kg of fructose syrup, 0.1kg of sodium chloride, 0.45kg of sodium citrate, 0.2kg of sodium phosphate, 0.65kg of sodium isovitamin C, 0.003kg of ethyl maltol, 0.07kg of citric acid, and add to ...

Embodiment 2

[0017] Collect fresh perilla leaves, select and remove inedible parts, clean them, dry them until the moisture content of perilla leaves is less than 8%, and then crush them into powder with a universal grinder. Weigh dry perilla leaf powder, mix it with water at a weight ratio of 1:20, treat it at a microwave power of 300W to a temperature of 50°C, add cellulase for enzymatic hydrolysis (1600U / g of enzyme added) and keep soaking Extracted for 50 minutes, filtered, and the filtrate was placed in a clean container for later use; the filter residue and water were mixed at a mass ratio of 1:20, treated at a microwave power of 300W until the temperature was 90°C, leached at a constant temperature for 30 minutes, and the heating was stopped. Filter and mix the two filtrates for later use.

[0018] Weigh 65kg of white granulated sugar, 19kg of fructose syrup, 0.125kg of sodium chloride, 0.5kg of sodium citrate, 0.25kg of sodium phosphate, 0.7kg of sodium isovitamin C, 0.004kg of eth...

Embodiment 3

[0020] Collect fresh perilla leaves, select and remove inedible parts, clean them, dry them until the moisture content of perilla leaves is less than 8%, and then crush them into powder with a universal grinder. Weigh dry perilla leaf powder, mix it with water at a weight ratio of 1:25, treat it at a microwave power of 400W to a temperature of 50°C, add cellulase for enzymatic hydrolysis (1600U / g of enzyme added) and keep soaking Extracted for 60 minutes, filtered, and the filtrate was placed in a clean container for later use; the filter residue and water were mixed at a mass ratio of 1:25, treated at a microwave power of 400W until the temperature was 90°C, leached for 30 minutes at a constant temperature, and the heating was stopped. Filter and mix the two filtrates for later use.

[0021] Weigh 70kg of white granulated sugar, 20kg of fructose syrup, 0.125kg of sodium chloride, 0.55kg of sodium citrate, 0.3kg of sodium phosphate, 0.75kg of sodium isovitamin C, 0.005kg of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com