TCS intelligent coarse slime sorting machine

A technology of coarse coal slime and separator, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of inapplicability, clean coal loss, etc., to improve the separation accuracy, increase the ash content of tailings, The effect of improving the product recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

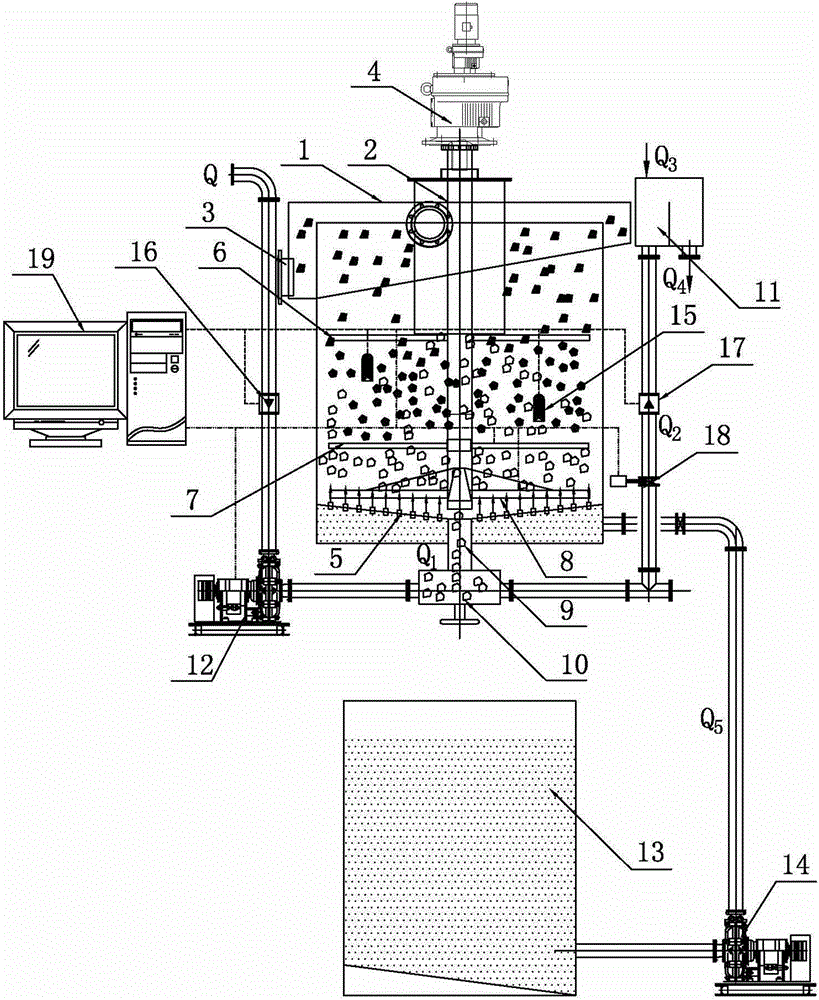

[0039] Attached below figure 1 Embodiments of the present invention are further described.

[0040] TCS Intelligent Coarse Slime Separator is an intelligent coarse slime separator that relies on the combined action of rising water flow and intelligent disruptor and has power interference. The coarse coal slime after classification and concentration enters the central material barrel 2 through the pipeline tangentially, and evenly feeds the coarse coal slime into the middle and upper part of the TCS intelligent coarse coal slime separator through the material inlet barrel 2. The top water bucket 13 is set at the lower part of the TCS intelligent coarse slime separator, and the top water is pressed into the water tank through the top water pump 14, and then fed into the sorting cylinder 1 from the lower part of the TCS intelligent coarse slime separator through the top water nozzle 5 , forming a steady upward current. The low-density coarse slime fed into the TCS intelligent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com