Method for preparing gold nanorods

A technology of gold nanorods and seeds, applied in the field of preparation of nanomaterials, can solve the problems of low reproducibility, poor quality of gold nanorods, severe operating requirements and experimental conditions, and achieve high yield and high consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

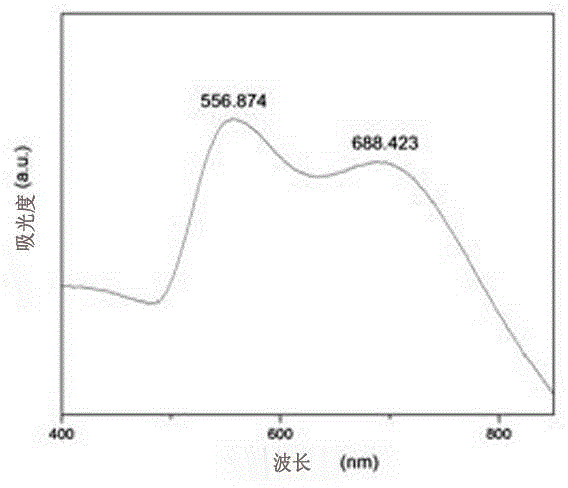

Embodiment 1

[0052] A. Preparation of growth solution: Weigh 7.0 g of cationic surfactant CTAB and 1.234 g of sodium oleate and dissolve in 250 mL of ultrapure water, heat and stir at 50 °C until completely dissolved. This process lasts for 1 hour. Vigorous stirring is not suitable during this process, and the degree of stirring is subject to the fact that the solution does not foam; then cool down to 30 °C, add 18 mL of 4 mM silver nitrate solution, stir slowly for 30 s, and stand at 30 °C for 15 minutes to achieve equilibrium ; followed by the addition of 250 mL of 1 mM HAuCl 4 solution, keep stirring for 90 minutes until the solution turns from golden yellow to clear; add 1.5 mL of concentrated hydrochloric acid with a mass fraction of 37 %, and stir slowly for 15 minutes to reach equilibrium; finally add 1.25 mL of 0.064 M ascorbic acid, and stir rapidly for 30 s , that is, the growth solution is prepared.

[0053] B. Preparation of seed solution: Weigh 0.3645 g cetyltrimethylammonium...

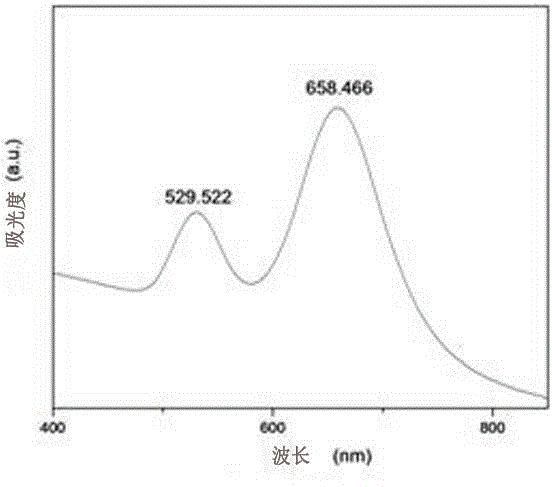

Embodiment 2

[0056] A. Preparation of growth solution: Weigh 9.0 g of cationic surfactant CTAB and 1.543 g of sodium oleate to dissolve in 250 mL of ultrapure water, heat and stir at 50 °C until completely dissolved, and this process lasts for about 1 hour. During this process, it is not advisable to stir violently, and the degree of stirring is subject to the fact that the solution does not foam; then cool down to 30 °C, add 18 mL of 4 mM silver nitrate solution, stir slowly for 30 s, and stand at 30 °C for 15 minutes or less. Equilibrium was reached; followed by the addition of 250 mL of 1 mM HAuCl 4 solution, keep stirring for 90 minutes until the solution turns from golden yellow to clear; add 1.5 mL of concentrated hydrochloric acid with a mass fraction of 37 %, and stir slowly for 15 minutes to reach equilibrium; finally add 1.25 mL of 0.064 M ascorbic acid, and stir rapidly for 30 After s, the growth solution is prepared;

[0057] B, the preparation of seed solution: same as embodi...

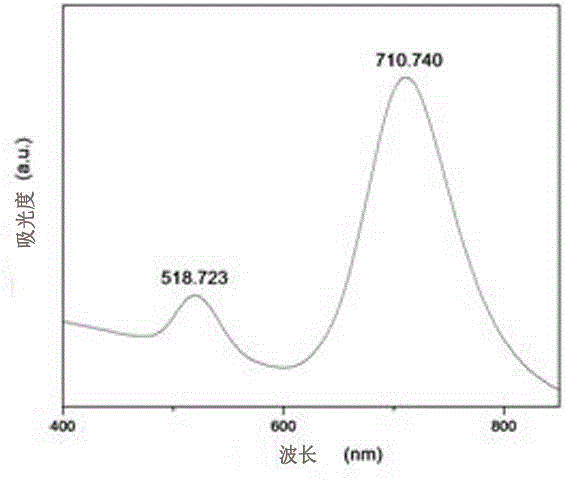

Embodiment 3

[0060] A. Preparation of growth solution: Weigh 9.0 g of cationic surfactant CTAB and 1.543 g of sodium oleate to dissolve in 250 mL of ultrapure water, heat and stir at 50 °C until completely dissolved, and this process lasts for about 1 hour. During this process, it is not advisable to stir violently, and the degree of stirring is subject to the fact that the solution does not foam; then cool down to 30 °C, add 18 mL of 4 mM silver nitrate solution, stir slowly for 30 s, and stand at 30 °C for 15 minutes or less. Equilibrium was reached; followed by the addition of 250 mL of 1 mM HAuCl 4 solution, keep stirring for 90 minutes until the solution turns from golden yellow to clear; add 2.1 mL of concentrated hydrochloric acid with a mass fraction of 37 %, and stir slowly for 15 minutes to reach equilibrium; finally add 1.25 mL of 0.064 M ascorbic acid, and stir rapidly for 30 After s, the growth solution is prepared;

[0061] B, the preparation of seed solution: identical with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com