Method for preparing Beta zeolite molecular sieve with excessive chiral polymorph A under acidic condition

A beta zeolite, acid condition technology, applied in the field of beta zeolite molecular sieve preparation, can solve the problems of high cost, harsh conditions, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

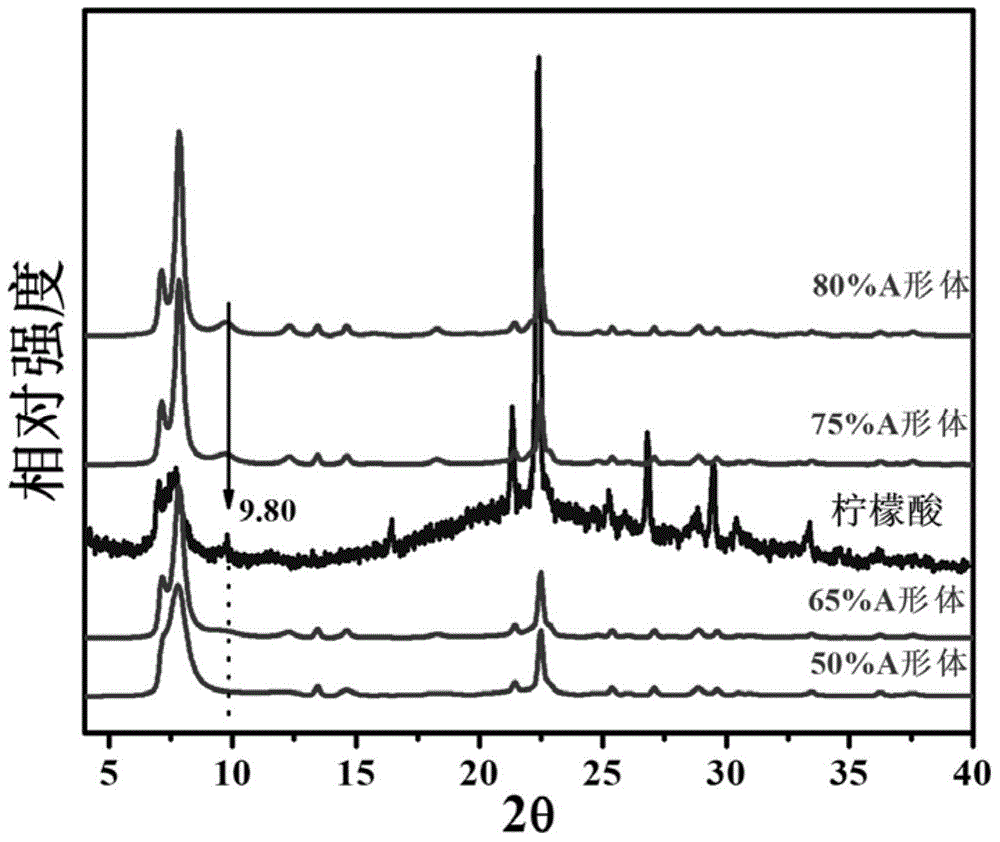

[0025] Example 1: Using citric acid as acid auxiliary

[0026] Weigh 4.50g of ethyl orthosilicate and 2.22g of 35% tetraethylammonium hydroxide aqueous solution in a plastic beaker in turn, add 4g of distilled water, seal the beaker with a sealing film and stir for 5 hours to make the ethyl orthosilicate The ester is completely hydrolyzed. Remove the sealing film, continue stirring for 6 hours in the fume hood, volatilize the ethanol and water in the system to form a gel, and transfer it to the freezer (material temperature 20 °C, cold trap temperature -60 °C, the temperature has no obvious effect on the experimental system, Water removal is the key factor) freeze-dried in a dryer for 3 days, at this time the H of the system 2 O and SiO 2 The molar ratio is less than 1, and the product mass is 2.4 g.

[0027] Mix 2.4g of solid glue block with 0.5g of citric acid and 0.2g of ammonium fluoride and grind it into a uniform powder (100 mesh), then transfer it to a stainless stee...

Embodiment 2

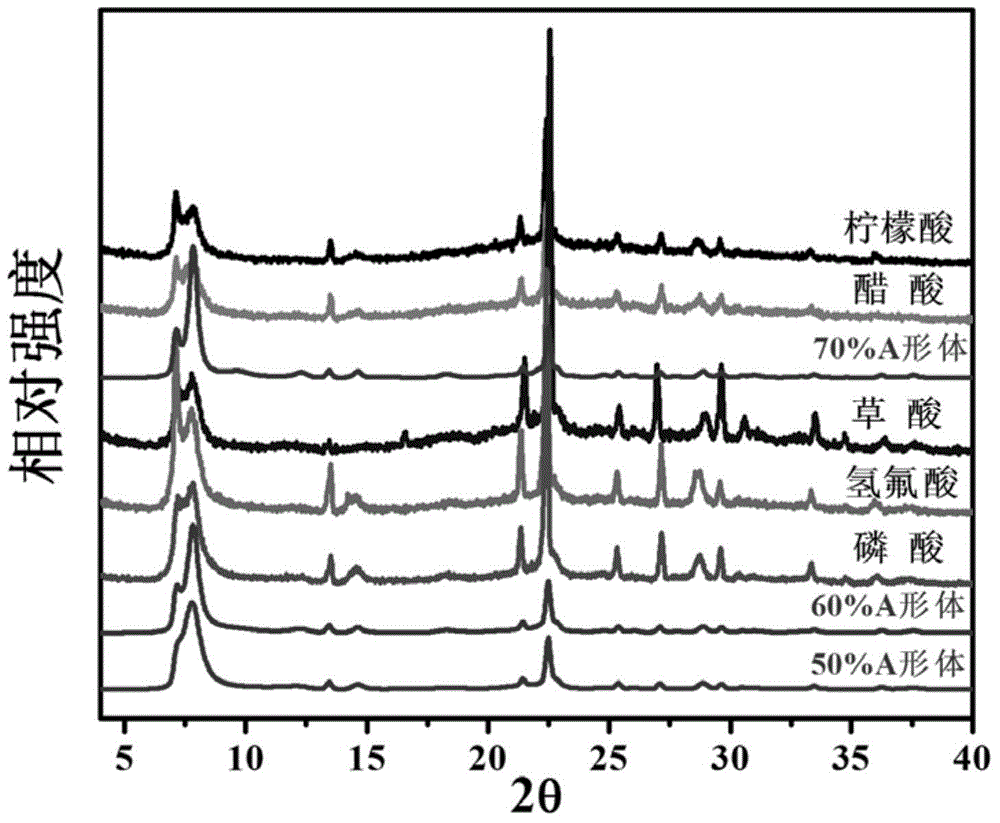

[0029] Embodiment 2: take acetic acid as acid auxiliary

[0030] Weigh 4.50g of ethyl orthosilicate and 2.22g of 35% tetraethylammonium hydroxide aqueous solution in a plastic beaker in turn, add 4g of distilled water, seal the beaker with a sealing film and stir for 5 hours to make the ethyl orthosilicate The ester is completely hydrolyzed. Remove the sealing film, continue stirring in the fume hood for 6 hours, volatilize the ethanol and water in the system to form a gel, and transfer it to a freeze dryer (material temperature 20 °C, cold trap temperature -60 °C, the temperature has no obvious effect on this experimental system. Influence, except water is the key factor) lyophilized for 3 days, at this time the H of the system 2 O and SiO 2 The molar ratio is less than 1, and the product mass is 2.4 g.

[0031] Grind 2.4g of solid gel blocks into powder (100 mesh), slowly add 120 μL of acetic acid and 225 μL of hydrofluoric acid (aqueous solution with a mass fraction of 4...

Embodiment 3

[0033] Embodiment 3: take oxalic acid as acid auxiliary

[0034] Weigh 4.50g of tetraethyl orthosilicate and 2.22g of 35% tetraethylammonium hydroxide aqueous solution in order in a plastic beaker, add 3g of distilled water, seal the beaker with a sealing film and stir for 5 hours to make the ethyl orthosilicate The ester is completely hydrolyzed. Remove the sealing film, continue stirring in the fume hood for 6 hours, volatilize the ethanol and water in the system to form a gel, and transfer it to a freeze dryer (material temperature 20 °C, cold trap temperature -60 °C, the temperature has no obvious effect on this experimental system. Influence, except water is the key factor) lyophilized for 3 days, at this time the H of the system 2 O and SiO 2 The molar ratio is less than 1, and the product mass is 2.4 g.

[0035]Mix 2.4g of solid glue block with 0.27g of oxalic acid and 0.19g of ammonium fluoride and grind it into a uniform powder (100 mesh), transfer it to a stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com