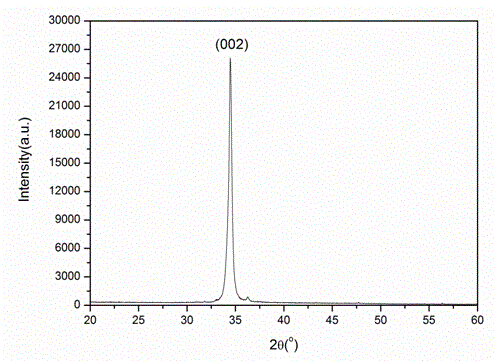

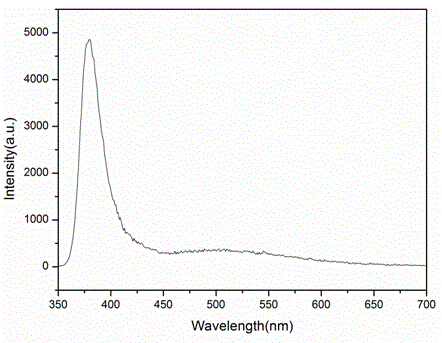

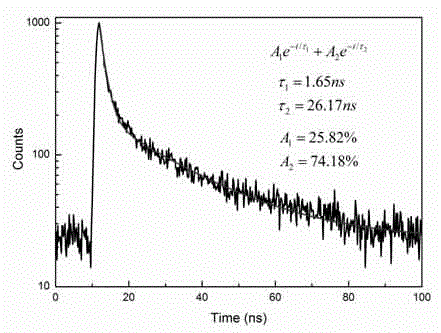

Preparation method of ultra-fast-flickering ZnO film

A thin-film, ultra-fast technology, applied in the field of materials science, can solve the problems of poor crystal quality and orientation, low luminescence intensity of excitons and defects in the film, and achieve strong ultra-fast decay performance, low cost, and improved crystal orientation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing an ultra-fast flashing ZnO thin film, specifically comprising the steps of:

[0020] (1) Calculated by volume ratio, the ratio of concentrated sulfuric acid: concentrated phosphoric acid is 3:1. After mixing concentrated sulfuric acid and concentrated phosphoric acid, the resulting mixed acid is heated to a temperature of 160°C, and a single crystal silicon wafer is placed in it. Keep the temperature at 160°C for 20 minutes, then cool naturally, pour out the mixed acid, and finally take out the monocrystalline silicon wafer, firstly clean it with alcohol, then perform ultrasonic cleaning, and finally blow dry to obtain the acid-treated monocrystalline silicon wafer sheet; the mass percent concentration of the concentrated sulfuric acid is 95-98%, and the concentrated phosphoric acid is an aqueous phosphoric acid solution with a mass percent concentration of 85%;

[0021] (2) The single crystal silicon wafer processed according to the above step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com