Method for reclaiming nutrient elements in hydrothermal liquidation waste water and equipment for using nutrient elements

A technology of hydrothermal liquefaction and nutrient elements, applied in sterilization methods, chemical instruments and methods, and microorganism-based methods, etc., can solve problems such as incomplete degradation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the treated hydrothermal liquefaction wastewater had an initial COD of 195,600 mg / L, a TN concentration of 11,900 mg / L, a TP concentration of 1,240 mg / L, and a pH of 12.6.

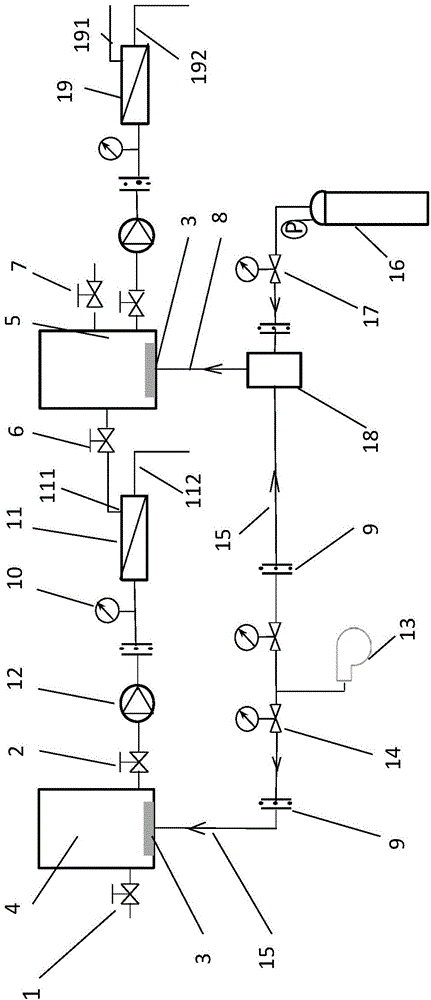

[0037] like figure 1 , the equipment for comprehensive treatment of hydrothermal liquefaction wastewater includes: photosynthetic bacteria incubator 4, microalgae incubator 5, photosynthetic bacteria filter unit, microalgae filter unit, air intake unit;

[0038] The photosynthetic bacteria incubator 4 is a cylindrical light-transmitting plexiglass container, which is provided with a waste water inlet 1 and a water outlet 2. The bottom of the photosynthetic bacteria incubator 4 is provided with an aeration pan 3 for feeding air, and the aeration pan 3 is connected with the air. Gas line 15 is connected. The wastewater inlet 1 is set at a distance of 15-20 cm from the bottom of the incubator, and the water outlet 2 is set at a position slightly higher than the aeration pan (1.5-2 cm ...

Embodiment 2

[0050] In this example, the initial and diluted properties of the treated hydrothermal liquefaction wastewater are the same as in Example 1, and the same equipment as in Example 1 is used, and the comprehensive treatment steps are as follows:

[0051] 1. Through the water pump, pump the hydrothermal liquefaction waste water, dilution water and photosynthetic bacteria liquid from the water inlet 1 to the photosynthetic bacteria incubator 4, control the total volume of the three liquids to be about 2 / 3 of the photosynthetic bacteria incubator 4, and the photosynthetic bacteria incubator 4 The bacterial inoculation amount is 0.25g / L dry weight, and the pH value in the wastewater is adjusted to 7.0;

[0052] Two, open the air compressor 14, open the air pressure control valve, adjust the rotameter 9, make the air enter the photosynthetic bacteria incubator 4 through the air intake pipeline 15, the aeration disc 3, and the photosynthetic bacteria in the waste water are mixed and con...

Embodiment 3

[0062] In this example, the initial and diluted properties of the treated hydrothermal liquefaction wastewater are the same as in Example 1, and the same equipment as in Example 2 is used, and the comprehensive treatment steps are as follows:

[0063] 1. Through the water pump, pump the hydrothermal liquefaction waste water, dilution water and photosynthetic bacteria liquid from the water inlet 1 to the photosynthetic bacteria incubator 4, control the total volume of the three liquids to be about 2 / 3 of the photosynthetic bacteria incubator 4, and the photosynthetic bacteria incubator 4 The bacterial inoculation amount is 0.30g / L dry weight, and the pH value in the wastewater is adjusted to 7.0;

[0064] Two, open the air compressor 14, open the air pressure control valve, adjust the rotameter 9, make the air enter the photosynthetic bacteria incubator 4 through the air intake pipeline 15, the aeration disc 3, and the photosynthetic bacteria in the waste water are mixed and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com