Nano cement paste

A nano-water and mud technology, applied in the field of nano-cement slurry, can solve problems such as hidden dangers of water conservancy or tunnel engineering, large strength attenuation, etc., and achieve the effect of improving penetration ability, improving late strength, and effectively blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of nano cement slurry, the composition of the mass parts of described nano cement slurry is as follows: 40 parts of Portland cement, 12 parts of modified nano silicon dioxide, 10 parts of nano magnesium oxide, 0.08 part of retarder hydroxyethylidene diphosphonic acid , 0.8 parts of tributyl phosphate defoamer, 4 parts of soot, 0.8 parts of polypropylene fiber, 0.2 parts of glass fiber, 4 parts of anti-gas channeling agent, 2 parts of early strength agent.

[0020] Wherein, the mass parts composition of the anti-gas channeling agent is as follows: 6 parts of styrene-butadiene latex, 5 parts of carboxylated styrene-butadiene latex, 0.02 parts of AMPS-AM-AA polymer, 4 parts of nonylphenol polyoxyethylene ether, ethylene glycol 2 parts, 10 parts of water.

[0021] Wherein, the accelerator is selected from liquid silicon dioxide.

[0022] Wherein, the particle size of the liquid silicon dioxide is 20nm.

[0023] Wherein, the modified nano-silica is prepared by the f...

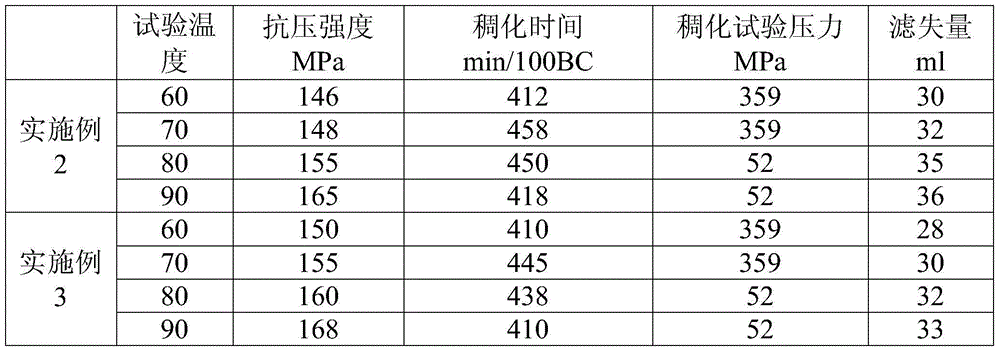

Embodiment 2

[0025] A kind of nano cement slurry, the composition of the mass parts of described nano cement slurry is as follows: Portland cement 45 parts, modified nano silicon dioxide 15 parts, nano magnesium oxide 12 parts, retarder hydroxyethylidene diphosphonic acid 0.12 parts 1.2 parts of defoaming agent tributyl phosphate, 6 parts of soot, 1.2 parts of polypropylene fiber, 0.4 part of glass fiber, 5 parts of anti-gas channeling agent, 3 parts of early strength agent.

[0026] Wherein, the mass parts composition of the anti-gas channeling agent is as follows: 7 parts of styrene-butadiene latex, 6 parts of carboxylated styrene-butadiene latex, 0.03 parts of AMPS-AM-AA polymer, 5 parts of nonylphenol polyoxyethylene ether, ethylene glycol 3 parts, 12 parts of water.

[0027] Wherein, the early strength agent is selected from liquid silicon dioxide and calcium formate.

[0028] Wherein, the particle size of the liquid silicon dioxide is 30nm.

[0029] Wherein, the modified nano-silic...

Embodiment 3

[0031] A kind of nano cement slurry, the composition of the mass parts of described nano cement slurry is as follows: 50 parts of portland cement, 20 parts of modified nano silicon dioxide, 14 parts of nano magnesium oxide, 0.16 part of retarder hydroxyethylidene diphosphonic acid 1.5 parts of defoaming agent tributyl phosphate, 8 parts of soot, 1.6 parts of polypropylene fiber, 0.5 parts of glass fiber, 6 parts of anti-gas channeling agent, 4 parts of early strength agent.

[0032] Wherein, the mass parts composition of the anti-gas channeling agent is as follows: 8 parts of styrene-butadiene latex, 6.8 parts of carboxylated styrene-butadiene latex, 0.05 parts of AMPS-AM-AA polymer, 6 parts of nonylphenol polyoxyethylene ether, ethylene glycol 5 parts, 15 parts of water.

[0033] Wherein, the accelerator is selected from liquid silicon dioxide.

[0034] Wherein, the particle size of the liquid silicon dioxide is 40nm.

[0035] Wherein, the modified nano-silica is prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com