High-purity chito-oligosaccharide controlled release fertilizer based on separation techniques and preparing method thereof

A separation technology and slow-release fertilizer technology, applied in the field of high-purity chitosan oligosaccharide slow-release fertilizer and its preparation, can solve the problems of poor adaptability and great influence on nutrient release speed, so as to improve yield and quality, and increase soil air permeability , promote the effect of nutrient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

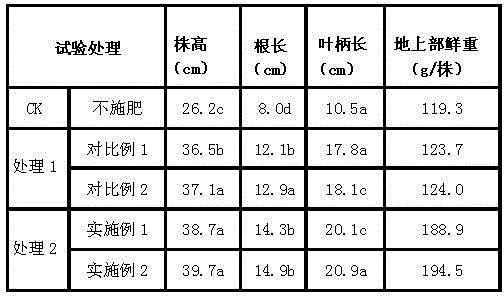

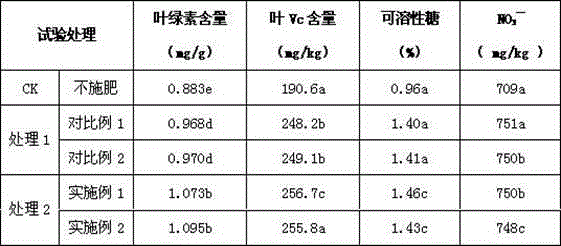

Examples

Embodiment 1

[0070] Oligochitosan slow release fertilizer, NPK (N-P 2 o 5 -K 2 O) content is respectively 18%, 4%, 18%, all are percentage by mass, and raw material composition is as follows:

[0071] 4% chitosan oligosaccharide coated urea 60 parts,

[0072] 60 parts of 6% chitosan oligosaccharide coated urea,

[0073] 225 parts of urea,

[0074] 100 parts of ammonium sulfate,

[0075] Superphosphate 150 parts,

[0076] Calcium magnesium phosphate fertilizer 90 parts,

[0077] Potassium sulfate 300 parts,

[0078] Humic acid 10 parts,

[0079] 5 parts of EDTA chelated trace elements;

[0080] Put the above-mentioned raw materials together into a blender and stir for 5-10 minutes, then fully mix, then measure and pack.

Embodiment 2

[0082] Oligochitosan slow release fertilizer, NPK (N-P 2 o 5 -K 2 O) content is 15%, 5%, 20% respectively, all are percentage by mass, and raw material composition is as follows:

[0083] 4% chitosan oligosaccharide coated urea 50 parts,

[0084] 6% chitosan oligosaccharide coated urea 50 parts,

[0085] 190 parts of urea,

[0086] 90 parts of ammonium sulfate,

[0087] 175 parts of superphosphate,

[0088] Calcium magnesium phosphate fertilizer 100 parts,

[0089] Potassium sulfate 330 parts,

[0090] Humic acid 10 parts,

[0091] 5 parts of EDTA chelated trace elements;

[0092] Put the above-mentioned raw materials together into a blender and stir for 5-10 minutes, then fully mix, then measure and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com