Preparation method of novel hydroxyapatite graft polylactic acid

A technology of hydroxyapatite and polylactic acid, which is applied in medical science, prosthesis and other directions, can solve the problems of easy agglomeration of hydroxyapatite, complex system and high cost, and achieves good biocompatibility, simple post-processing, and method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

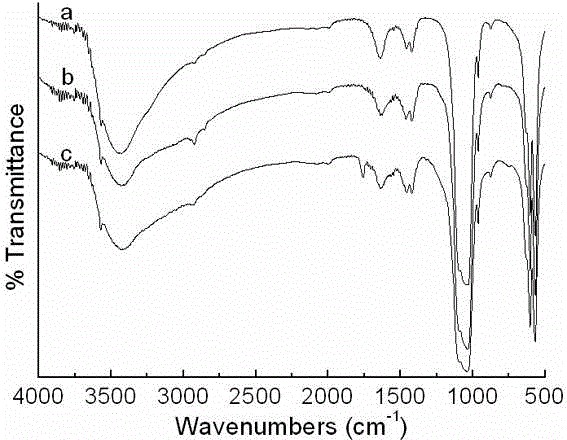

Image

Examples

Embodiment 1

[0018] The preparation method of the novel hydroxyapatite grafted polylactic acid of this embodiment is as follows:

[0019] (1) Dissolve 3-aminopropyltriethoxysilane (3.5mL, 0.015mol) in a mixed solution of ethanol and water (350mL), hydrolyze it at room temperature for 0.5h, and then add hydroxyapatite (HA) ( 4g, 0.01mol), stirred and reacted for 6h, then centrifuged the reacted product, dried at 50℃ for 12h, washed the dried product with ethanol, and then vacuum dried the washed product to moisture content <20ppm, get hydroxyapatite (SiHA) with -NH2 on the surface;

[0020] (2) Dissolve polylactic acid (0.9g, 0.01mol) containing terminal carboxyl groups in anhydrous dichloromethane, and then add N,N'-carbonyldiimidazole (CDI) (3.2g, 0.02mol) at 0℃ , The carboxyl group is activated for 0.5h under the condition of stirring speed of 300r / min, and then the hydroxyapatite with amino group on the surface (5.1g, 0.01mol) is added to the polylactic acid solution, and the reaction is 8h....

Embodiment 2

[0023] The preparation method of the novel hydroxyapatite grafted polylactic acid of this embodiment is as follows:

[0024] (1) Dissolve 3-aminopropyltriethoxysilane (4.7mL, 0.02mol) in a mixed solution (470mL) of ethanol and water, hydrolyze at room temperature for 2h, and then dissolve hydroxyapatite (4g, 0.01mol) ) Was added to the mixed solution, stirred and reacted for 8h, then centrifuged the reacted product, dried at 50℃ for 12h, washed the dried product with ethanol, and then vacuum dried the washed product to moisture content <20ppm, get hydroxyapatite (SiHA) with -NH2 on the surface;

[0025] (2) Dissolve polylactic acid (1.8g, 0.02mol) containing terminal carboxyl groups in anhydrous dichloromethane, then add N,N'-carbonyldiimidazole (9.6g, 0.06mol) to the polylactic acid solution, Activate the carboxyl group (activation temperature 0℃, activation time 2h), then add hydroxyapatite (5.1g, 0.01mol) with amino groups on the surface to the polylactic acid solution, stir and...

Embodiment 3

[0027] The preparation method of the novel hydroxyapatite grafted polylactic acid of this embodiment is as follows:

[0028] (1) Dissolve 3-aminopropyltriethoxysilane (5.80mL, 0.025mol) in a mixed solution of ethanol and water (580mL), hydrolyze at room temperature for 1h, and then dissolve hydroxyapatite (4g, 0.01mol) ) Add to the mixed solution, stir and react for 7h, then centrifuge the reacted product, dry at 50℃ for 12h, wash the dried product with ethanol, and then vacuum dry the washed product to moisture content <20ppm, get hydroxyapatite (SiHA) with -NH2 on the surface;

[0029] (2) Dissolve polylactic acid (2.7g, 0.03mol) containing terminal carboxyl groups in anhydrous dichloromethane, then add N,N'-carbonyldiimidazole (19.2g, 0.012mol) into the polylactic acid solution, Activate the carboxyl group (activation temperature 0℃, activation time 1h), and then add hydroxyapatite (5.1g, 0.01mol) with amino groups on the surface to the polylactic acid solution, stir and react a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com