A method and system for producing synthetic natural gas or co-production of hydrogen by combined use of circulating fluidized bed dry thermal desulfurization

A circulating fluidized bed, synthetic natural gas technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of flying temperature, increased investment cost, unfavorable reactor installation and disassembly, etc., to control temperature rise, equipment The effect of material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

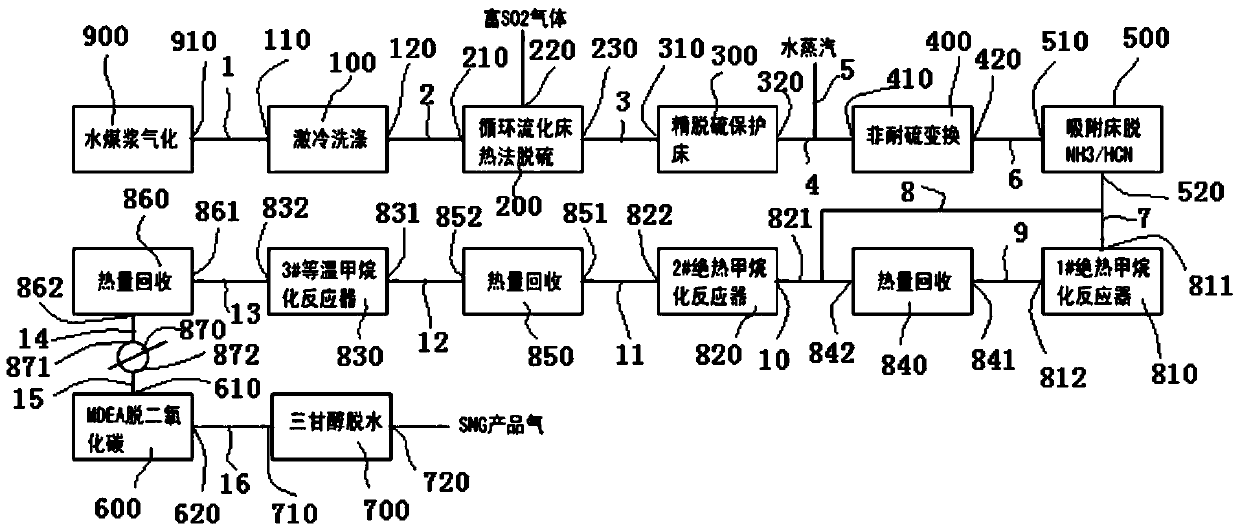

Embodiment 1

[0138] see figure 1 , the combined use of circulating fluidized bed dry desulfurization production synthetic natural gas system shown in the figure, including chilling washing device 100, circulating fluidized bed thermal desulfurization device 200, fine desulfurization guard bed device 300, non-sulfur-tolerant conversion device 400 , adsorption bed to remove NH 3 / HCN device 500, SNG product gas production device, MDEA carbon dioxide removal device 600, triethylene glycol dehydration device 700. The SNG product gas production device includes adiabatic methanation reactors 810 , 820 , isothermal methanation reactor 830 , heat recovery devices 840 , 850 , 860 and cooling device 870 .

[0139] The crude syngas input port 110 of the chilling washing device 100 is connected to the crude syngas output port 910 of the coal-water slurry gasification device 900 through a pipeline 1 .

[0140] The crude synthesis gas input port 210 of the circulating fluidized bed thermal desulfuriza...

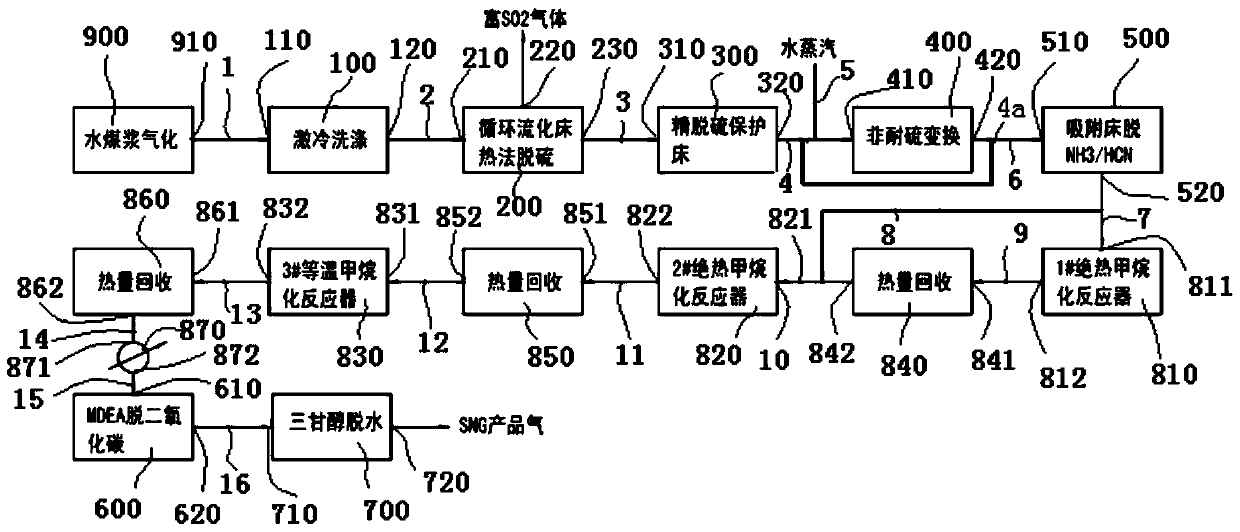

Embodiment 2

[0162] see figure 2 , the combined use of circulating fluidized bed dry desulfurization production of synthetic natural gas system shown in the figure is basically the same as the system of combined use of circulating fluidized bed dry desulfurization production of synthetic natural gas in Example 1, the difference lies in the high temperature The finely desulfurized syngas is divided into two streams, one is connected to the 410 high-temperature finely desulfurized syngas inlet of the non-sulfur-resistant shift 400 device through the pipeline 4; the other is connected to the pipeline 6 through the pipeline 4a. And the content of active component Ni and other compositions of the catalyst used for the methanation reaction in the methanation boundary zone are different from those in Example 1.

[0163] The working process of the combined use of circulating fluidized bed dry desulfurization to produce synthetic natural gas system of this embodiment is as follows:

[0164] The c...

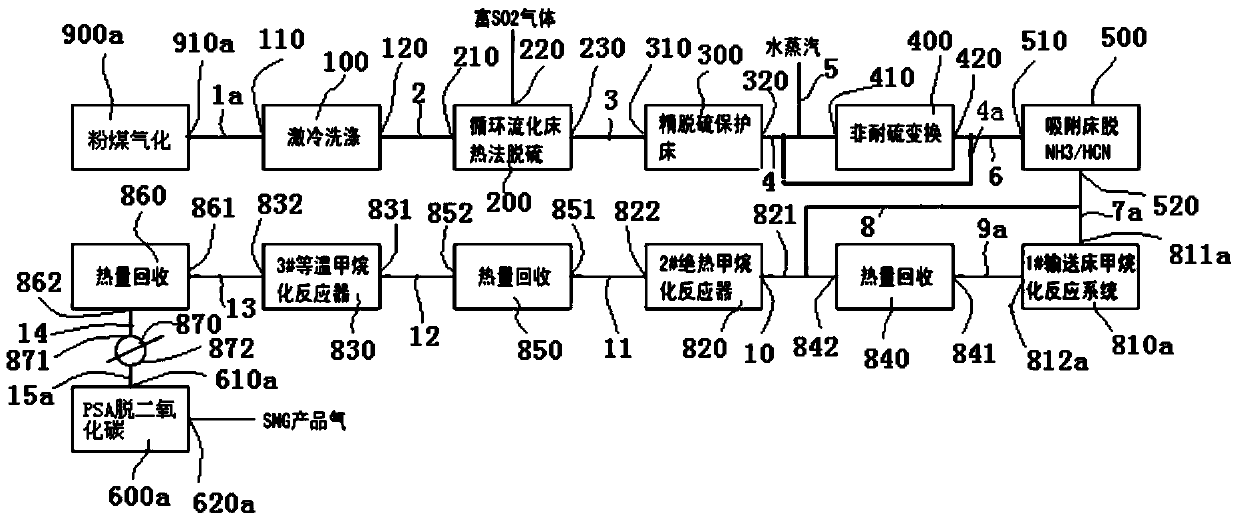

Embodiment 3

[0172] see image 3 , the combined use of circulating fluidized bed dry desulfurization production of synthetic natural gas system shown in the figure is basically the same as the system of combined use of circulating fluidized bed dry desulfurization production of synthetic natural gas in Example 2, the difference lies in the use of PSA carbon dioxide removal device 600a Instead of the MDEA carbon dioxide removal device 600 and canceling the triethylene glycol dehydration device 700, the SNG product gas outlet 620a of the PSA carbon dioxide removal device 600a directly sends out the SNG product gas. Replace the adiabatic methanation reactor 810 in Example 1 with the transport bed methane reaction device 810a, and the adsorption bed removes NH 3 Two pipelines 7a and 8 come out from the outlet 520 of the de-impurity conversion synthesis gas of / HCN device 500, and the pipeline 7a is connected with the de-impurity conversion synthesis gas inlet 811a of the transport bed methane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com