Solar absorbing film and preparation method thereof

A solar absorbing and absorbing layer technology, applied in the field of solar absorbing films, can solve problems such as low infrared radiation rate, achieve the effects of improving overall performance, ensuring work reliability, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of nano-gradient solar spectrum selective absorption film coating by DC magnetron reactive sputtering method:

[0035] Equipment preparation:

[0036] A magnetron sputtering apparatus model JGP500A, which is equipped with three 75mm permanent magnet magnetron targets, and the maximum sputtering power is 500W. A four-station sample turntable with revolution function can realize three-target co-sputtering experiment. The sample can be heated or water-cooled, the maximum temperature can reach 800°C, and the heating rate can be adjusted from 10°C / min to 50°C / min, which is suitable for preparing films of various materials. The vacuum system is mainly equipped with a 2XZ-8 (8L / S) mechanical pump and FF-200 / 1200 vortex molecular pump. The highest vacuum degree can reach 6.010-6Pa. The ultra-high vacuum degree provides a guarantee for the precise control of the film composition .

[0037] Material preparation:

[0038]The sputtering targets are respectively 99....

Embodiment 2

[0046] On the basis of Example 1, the absorbing layer in Example 1 adopts a multi-level layered structure, and alternately deposits multi-layer films. Ni-TiNxOy (Ni) is one cycle, a total of three cycles, modulated into a composition gradient Variations in composite membranes.

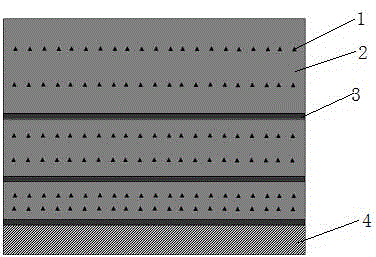

[0047] Set 3 samples to precisely control the composition of the absorbing layer through two changes, as shown in samples 1 to 3 in Table 1: change the doping amount of Ni in the absorbing functional layer, and the doping amount gradually decreases from bottom to top; as shown in Table 2 Sample Nos. 4 to 6 show that the ratio of the two sub-layer ceramic absorber layers TiNxOy(Ni) and the metal layer Ni is changed to prepare multilayer composite films with different composition gradients. Then pure AlN was deposited to a thickness of 50 nm. Such as figure 1 Shown: After obtaining the optimal composition gradient film, keep the composition gradient constant, and prepare composite films with different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com