Silicon solar cell rear silver paste with low silver content and preparation method therefor

A technology of solar cells and silver content, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of unstable long-term use performance, poor aging resistance, and limited reduction of silver content, and achieves a simple and easy preparation process , strong adhesion, and the effect of reducing silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below through specific examples. The contents of each example are only used for understanding the present invention, and should not be construed as limiting the protection scope of the present invention.

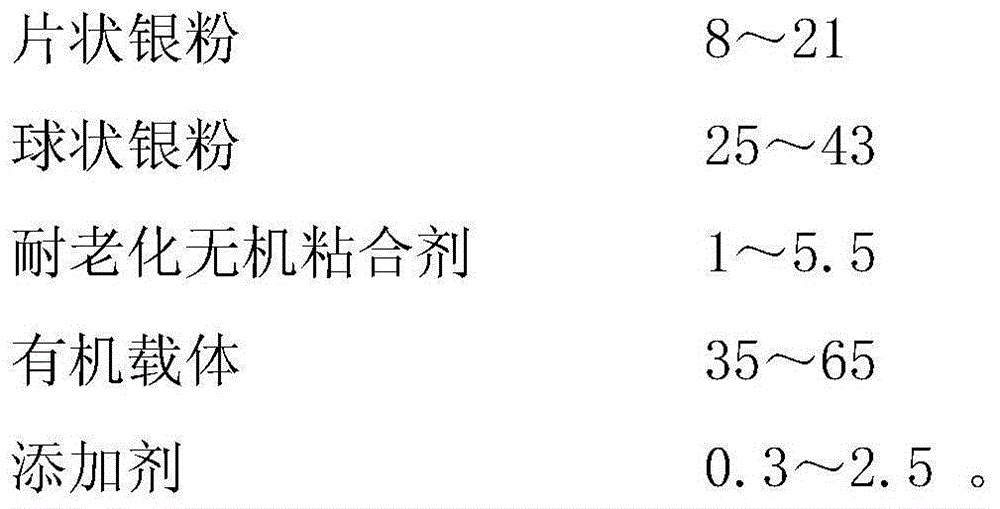

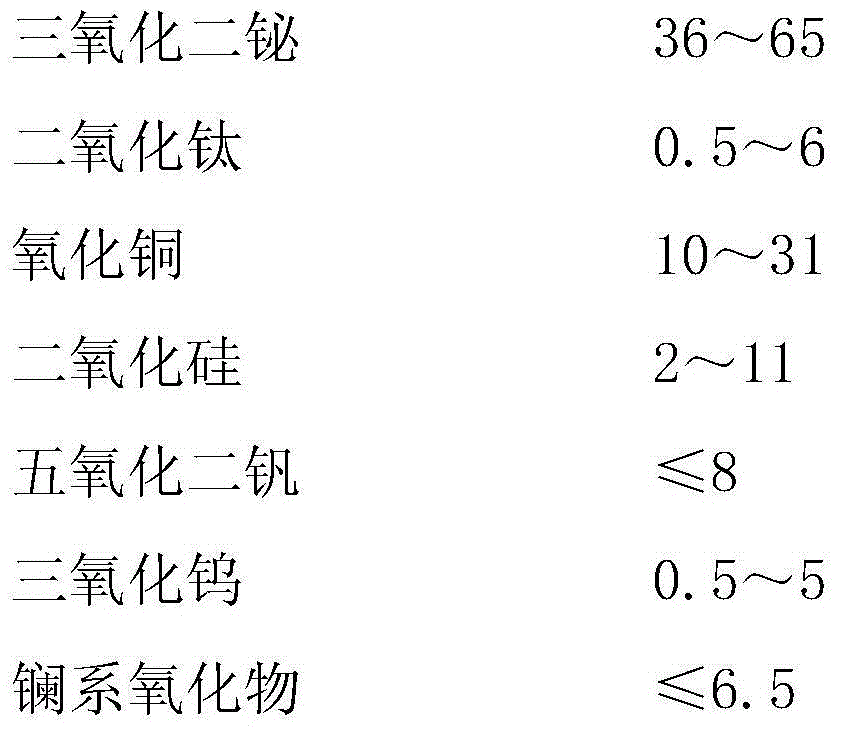

[0037] Using the raw materials, ratios, and process conditions shown in Table 1, the silver paste on the back of the crystalline silicon solar cell with low silver content was prepared.

[0038] Table 1 Raw materials and process conditions used in Examples 1-5 of the present invention

[0039]

[0040]

[0041] The detailed steps for preparing the silver paste on the back of the crystalline silicon solar cell with low silver content are as follows:

[0042] 1).Preparation of anti-aging inorganic adhesive

[0043]According to the raw materials and proportions shown in Table 1, mix the raw materials evenly and put them into the platinum crucible, heat the platinum crucible with a high-temperature furnace, and keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com