Film transistor, array substrate and preparation method thereof, display device

A technology of thin-film transistors and array substrates, applied in the display field, can solve problems such as rising production costs, scarcity of indium elements, and reduction of indium elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

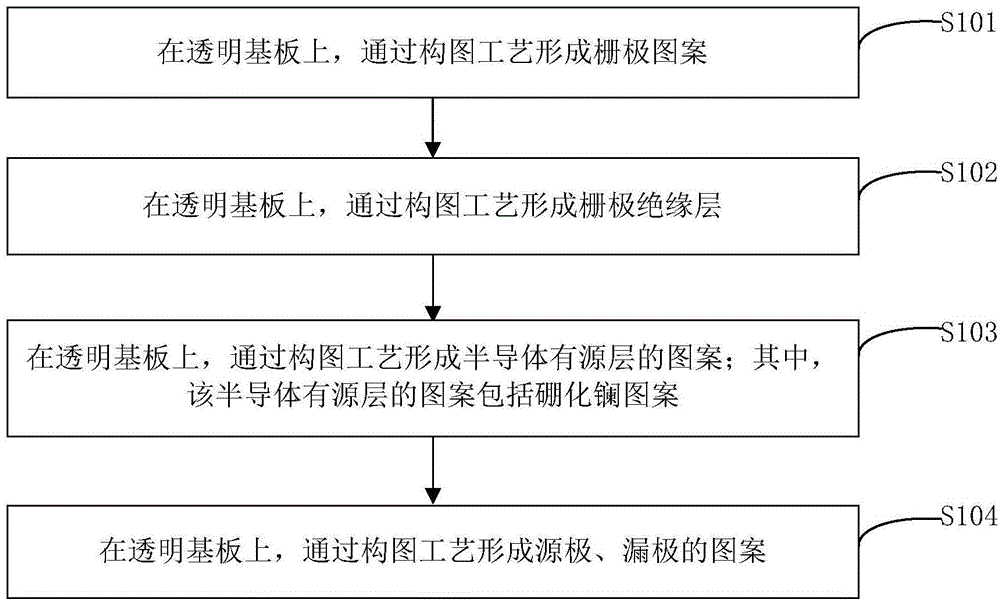

[0025] An embodiment of the present invention provides a method for preparing a thin film transistor, such as figure 1 As shown, can include:

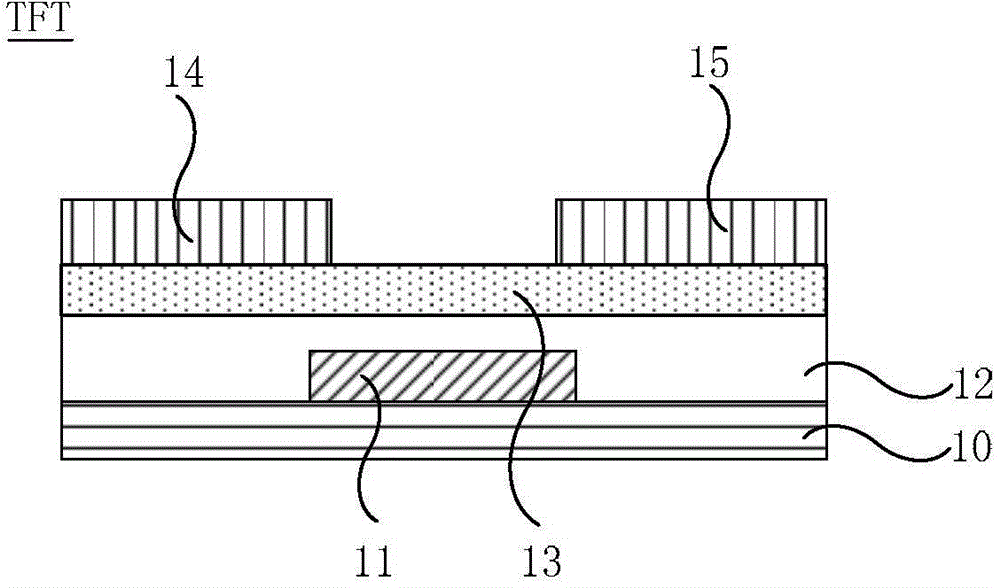

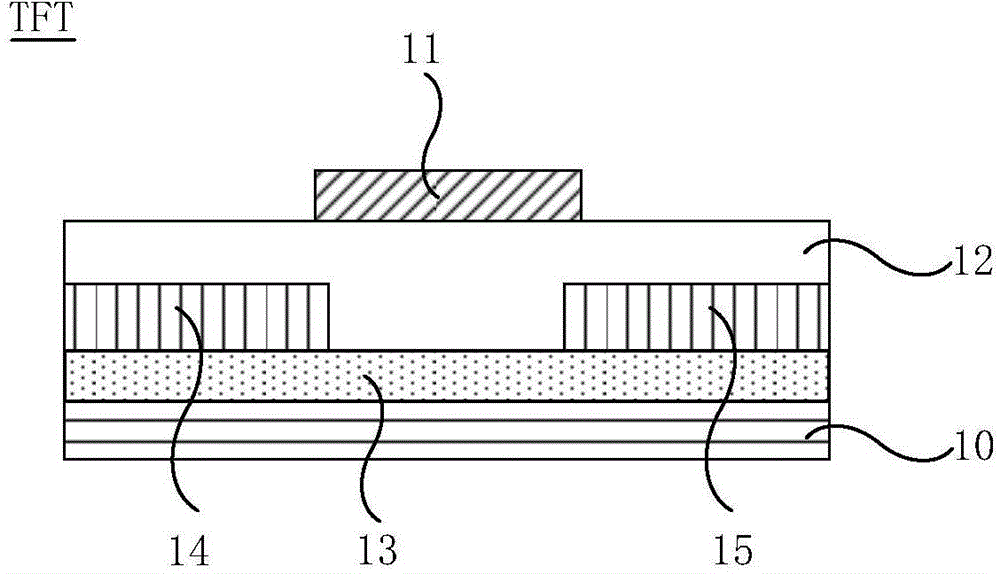

[0026] S101, such as Figure 2a As shown, on the transparent substrate 10, a gate pattern 11 is formed by a patterning process.

[0027] S102 , on the transparent substrate 10 , form a gate insulating layer 12 through a patterning process.

[0028] S103. On the transparent substrate 10, a pattern of the semiconductor active layer 13 is formed through a patterning process; wherein, the pattern of the semiconductor active layer 13 includes a lanthanum boride pattern.

[0029] S104 , on the transparent substrate 10 , forming patterns of the source electrode 14 and the drain electrode 15 through a patterning process.

[0030] It should be noted that, first, the present invention does not limit the sequence of the above steps S101 to S104. For example when a TFT such as Figure 2a When the bottom-gate thin film transistor is shown, the...

Embodiment 1

[0043] The preparation method provided in this embodiment is used to prepare such as Figure 2a The shown TFT, especially the semiconductor active layer 13 mainly composed of lanthanum boride, is prepared by physical vapor deposition in this embodiment, as image 3 As shown, the method for preparing TFT may include:

[0044] S201 , forming a pattern of the gate 11 on the transparent substrate 10 .

[0045] Specifically, on the transparent substrate 10, a gate metal layer with a thickness of 100 nm-2000 nm is prepared by physical vapor deposition. Wherein, the gate metal layer can be made of metal, metal alloy or conductive metal oxide. It can also be composed of more than two layers of conductive materials, such as two layers of molybdenum metal layers and an aluminum metal layer between the two layers of molybdenum metal layers, that is, Mo / Al / Mo (molybdenum / aluminum / molybdenum) and the like. Then, apply photoresist on the surface of the gate metal layer, and use a common ...

Embodiment 2

[0060] The preparation method provided in this embodiment is used to prepare such as Figure 2a Shown TFT, described method specifically comprises:

[0061] Firstly, an Al thin film with a thickness of 300 nm is formed on the transparent substrate 10, and the pattern of the gate 11 is formed through masking, exposure, etching and developing processes.

[0062] Next, a gate insulating layer 12 with a thickness of 200 nm is prepared by anodic oxidation on the substrate on which the pattern of the gate 11 is formed.

[0063] Next, on the substrate on which the gate insulating layer 12 is formed, a lanthanum boride film layer is prepared by sputtering.

[0064] Specifically, the lanthanum boride target is first installed on the sputtering apparatus, and a thin film is prepared by direct sputtering. During the sputtering process, the preparation pressure is controlled to be 0.3Pa, and the growth rate of the film is 10nm / min to form a thick film. 20nm lanthanum boride thin film la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com