Pittosporum tobira seedling substrate and preparation method thereof

The technology of a seedling-raising substrate and Pittosporum, which is applied in the field of garden seedling cultivation, can solve the problems of insufficient nutrients in the seedling-raising substrate, slow growth of seedlings, and low survival rate of seedlings, and achieve long-lasting fertilizer and water retention, high survival rate of seedlings, and increased growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

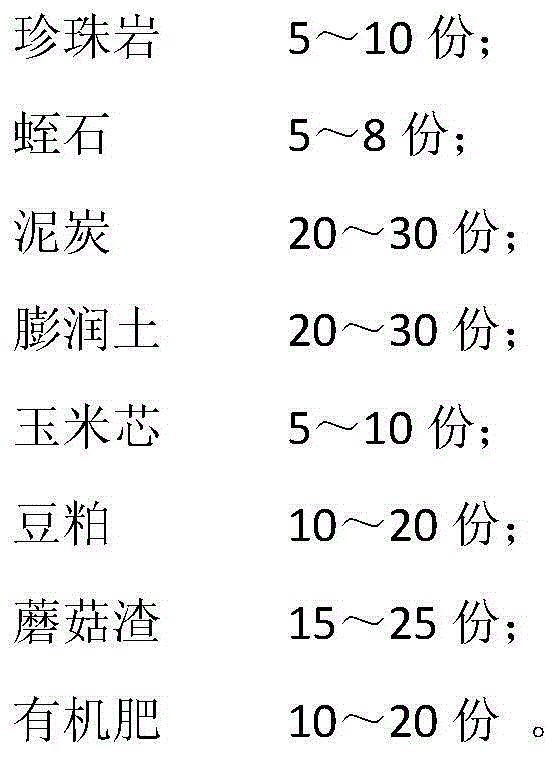

[0018] A Pittosporum seedling raising substrate, the substrate includes the following components and the parts by weight of each component are: 5 parts of perlite; 8 parts of vermiculite; 20 parts of peat; 30 parts of bentonite; 10 parts of corncob; 10 parts of soybean meal ; 25 parts of mushroom dregs; 20 parts of organic fertilizer.

[0019] Described organic fertilizer is cow dung.

[0020] Also include slow-release fertilizer in the described substrate, 5 parts.

[0021] The nitrogen content in the substrate is 200 mg / kg, the phosphorus content is 50 mg / kg, and the potassium content is 300 mg / kg.

[0022] The pH of the matrix is 5.3.

[0023] The preparation method of Pittosporum seedling raising substrate, comprises the following steps:

[0024] (1) Pulverizing corn cob and soybean meal, the particle size is 4mm;

[0025] (2) Weigh the crushed corn cob, soybean meal, mushroom dregs, and organic fertilizer according to the above parts by weight, and then cover with p...

Embodiment 2

[0028] A Pittosporum seedling raising substrate, the substrate includes the following components and the parts by weight of each component are: 10 parts of perlite; 5 parts of vermiculite; 30 parts of peat; 20 parts of bentonite; 5 parts of corn cob; 20 parts of soybean meal ; 15 parts of mushroom dregs; 10 parts of organic fertilizer.

[0029] Described organic fertilizer is pig manure.

[0030] Also include slow-release fertilizer in the described substrate, 5 parts.

[0031] The nitrogen content in the substrate is 600mg / kg, the phosphorus content is 300mg / kg, and the potassium content is 400mg / kg.

[0032] The pH of the matrix is 6.5.

[0033] The preparation method of Pittosporum seedling raising substrate, comprises the following steps:

[0034] (1) Pulverizing corn cob and soybean meal, the particle size is 4mm;

[0035] (2) Weigh the crushed corn cob, soybean meal, mushroom dregs, and organic fertilizer according to the above parts by weight, and then cover with ...

Embodiment 3

[0038] A Pittosporum seedling raising substrate, the substrate includes the following components and the parts by weight of each component are: 8 parts of perlite; 6 parts of vermiculite; 25 parts of peat; 28 parts of bentonite; 8 parts of corn cob; 15 parts of soybean meal ; 20 parts of mushroom dregs; 15 parts of organic fertilizer.

[0039] Described organic fertilizer is chicken manure.

[0040] Also include slow-release fertilizer in the described substrate, 5 parts.

[0041] The nitrogen content in the substrate is 400 mg / kg, the phosphorus content is 200 mg / kg, and the potassium content is 350 mg / kg.

[0042] The pH of the matrix is 7.2.

[0043] The preparation method of Pittosporum seedling raising substrate, comprises the following steps:

[0044] (1) Pulverizing corn cob and soybean meal, the particle size is 4mm;

[0045] (2) Weigh the crushed corn cob, soybean meal, mushroom dregs, and organic fertilizer according to the above parts by weight, and then cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com