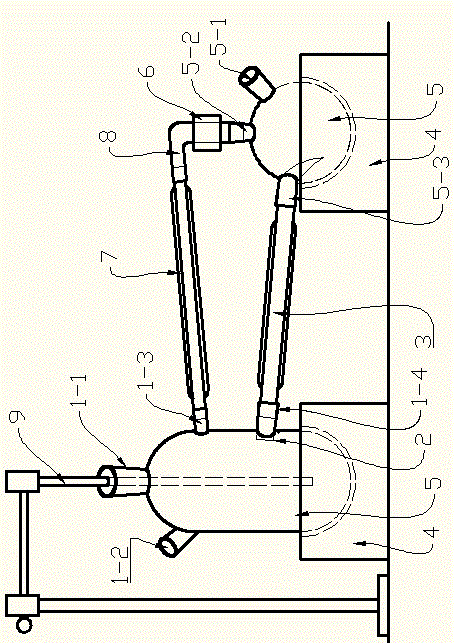

Ultrasonic continuous extraction device

An extraction device and ultrasonic technology, applied in the field of ultrasonic continuous extraction devices, can solve the problems of slow dissolution, speed up extraction, troublesome operation, etc., and achieve the effects of rapid separation, saving experimental time, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Taking a 100 g coal sample as an example, the extraction experiment was carried out with the ultrasonic continuous extraction device of the present invention.

[0049] Open the stopper of spare feeding port 1-2, and add 100 g of coal sample and 600 mL of acetone reagent into sample bottle 1 from this port; open the plug of solvent feeding port 5-1, and add 400 mL of acetone, the solvent to be used, into solvent bottle 5 , set the temperature of the heating jacket 4 to 65 o C starts heating, turns on the switch of the ultrasonic probe 8, and adjusts parameters such as 10 hours of ultrasonic time and 20 KHz of ultrasonic frequency. When the temperature reaches 65 o After C, closely observe the dynamics of the steam in the solvent vapor condensation pipe 8, and properly adjust the heating temperature to 68-70 o C, so that the vapor can smoothly rise to the top, and be condensed and returned to the sample bottle 1 in the solvent vapor return pipe 7 smoothly. After the ga...

Embodiment 2

[0051] Taking 100 g coal sample as an example, the extraction experiment was carried out by ultrasonic extraction.

[0052] Weigh 100 g of coal sample and place it in a 2000 mL large beaker, add 600 mL of acetone to it, then place the large beaker in an ultrasonic instrument, and the total ultrasonic time is 2 hours. After the ultrasonic is completed, take out the large beaker and let it stand for 4 hours After the coal sample has settled, use a vacuum filtration device to filter the coal sample and the extract to separate, and use a rotary evaporator to distill and concentrate the obtained filtrate to remove the reagent to obtain the extract, and put the obtained coal sample back into the large beaker. Once the ultrasonic extraction is completed, follow the above steps to repeat the extraction until the extraction is complete. After the extract is basically colorless, the acetone extraction is completed, and the ultrasonic extraction can be completed twice a day. The first-lev...

Embodiment 3

[0054] Taking 1 g coal sample as an example, the extraction experiment was carried out by Soxhlet extraction method.

[0055] Weigh 1 g of coal sample, put it into the folded and weighed filter paper, roll the filter paper into a paper roll with the lower end sealed, and carefully put it into the Soxhlet extractor, the size of the paper roll is just enough to be placed in the extraction tube It is appropriate. Fix the round-bottomed flask filled with 200 mL of acetone on the heating mantle, assemble the Soxhlet extractor and condenser tube with the coal sample together, and wrap the interface with raw material tape to avoid poor contact and solvent leakage. waste. Pass condensed water, turn on the heating mantle, adjust the heating power, keep the solvent from bumping, and when the extract is basically colorless, stop heating. After the extraction is complete, the primary extraction time with acetone is 6 days in total, and 200 mL of acetone reagent is consumed.

[0056] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com