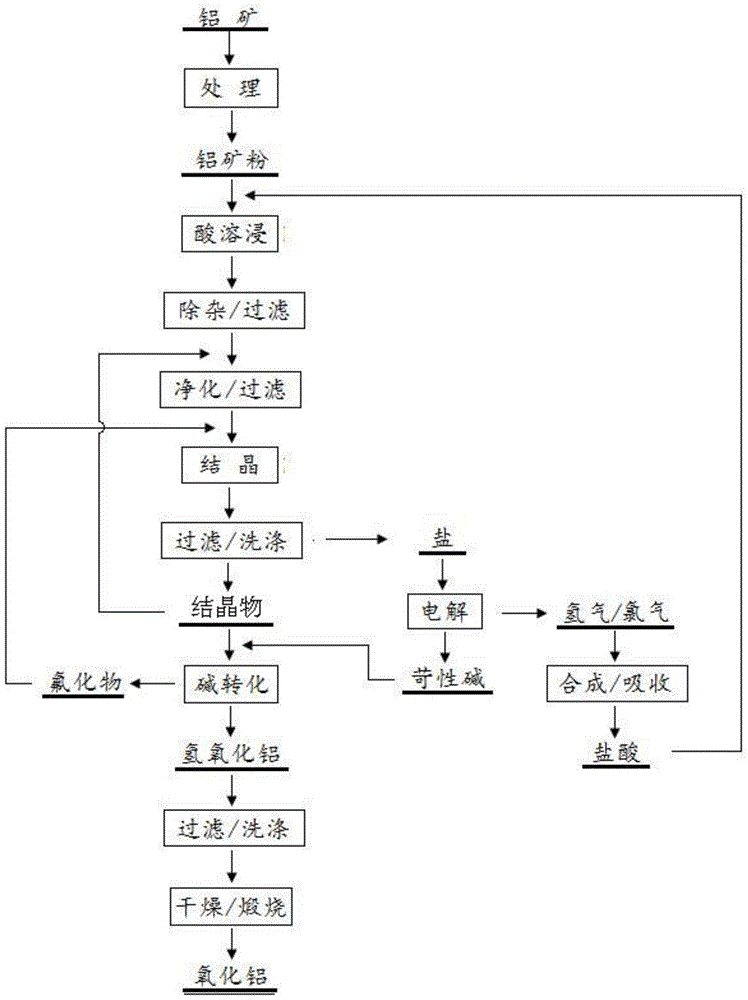

A method for producing alumina by treating low-aluminum minerals by acid method

A technology of alumina and minerals, which is applied in the field of non-ferrous metal mineral treatment and processing, and acid treatment of low-aluminum minerals to produce alumina. It can solve the problems of poor aluminum ion selectivity and difficulty in removing iron, and achieve environmental friendliness and equipment. The effect of low operating cost and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

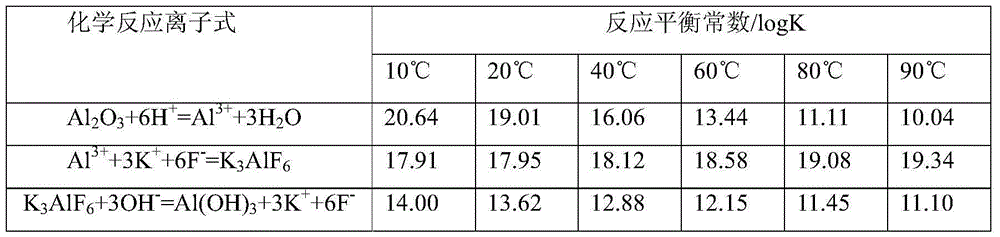

[0056] A method for producing alumina by acid treatment of low-aluminum minerals of the present invention, comprising the following steps:

[0057] 1) Wash and dry the minerals, roast them at 650-700°C for 25-30 minutes, and then grind them to a particle size of -200 mesh to obtain aluminum ore powder.

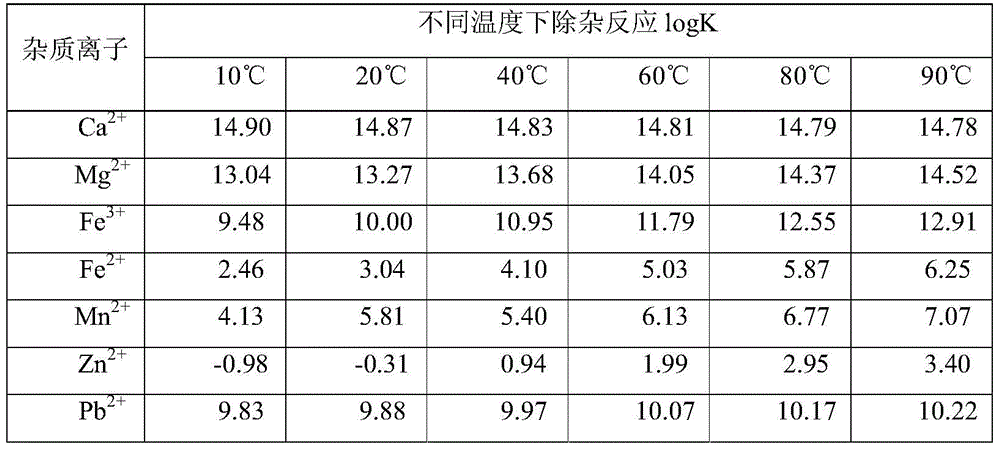

[0058] 2) Add the aluminum ore powder after step 1) to hydrochloric acid with a mass concentration of 15-16% (industrial concentrated hydrochloric acid is diluted with water at a ratio of 1:1), and then leaching in two stages of countercurrent at 90-95°C, each leaching time is 120 ~150min; the mass ratio of the total amount of acid to aluminum ore powder is 3.95~4.05. After filtration, the total dissolution rate of aluminum was 90.6%. The composition and content (g / L) of the leach solution are as follows: aluminum 40.0; iron 1.44; calcium 0.56; magnesium 0.62.

[0059] 3) Take the leaching solution and heat it up to 95°C in the impurity removal reaction kettle, then add 12.8...

Embodiment 2

[0064] A method for producing alumina by acid treatment of low-aluminum minerals of the present invention, comprising the following steps:

[0065] 1) Wash and dry the minerals, roast them at 650-700°C for 25-30 minutes, and then grind them to a particle size of -200 mesh to obtain aluminum ore powder.

[0066] 2) Add the aluminum ore powder after step 1) to hydrochloric acid with a mass concentration of 15-16% (industrial concentrated hydrochloric acid is diluted with water at a ratio of 1:1), and then leaching in two stages of countercurrent at 90-95°C, each leaching time is 120 ~150min; the mass ratio of the total amount of acid to aluminum ore powder is 3.95~4.05. After filtration, the total dissolution rate of aluminum was 90.6%. The composition and content (g / L) of the leach solution are as follows: aluminum 40.0; iron 1.44; calcium 0.56; magnesium 0.62.

[0067] 3) Take the leaching solution and heat it up to 80°C in the impurity removal reaction kettle, and then add ...

Embodiment 3

[0072] A method for producing alumina by acid treatment of low-aluminum minerals of the present invention, comprising the following steps:

[0073] 1) Wash and dry the minerals, roast them at 650-700°C for 25-30 minutes, and then grind them to a particle size of -200 mesh to obtain aluminum ore powder.

[0074] 2) Add the aluminum ore powder after step 1) to hydrochloric acid with a mass concentration of 15-16% (industrial concentrated hydrochloric acid is diluted with water at a ratio of 1:1), and then leaching in two stages of countercurrent at 90-95°C, each leaching time is 120 ~150min; the mass ratio of the total amount of acid to aluminum ore powder is 3.95~4.05. After filtration, the total dissolution rate of aluminum was 90.6%. The composition and content (g / L) of the leach solution are as follows: aluminum 40.0; iron 1.44; calcium 0.56; magnesium 0.62.

[0075] 3) Take the leaching solution and heat it up to 50°C in the impurity removal reaction kettle, then add 13.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com