Method for synthesizing n-butyl acetate

A technology of n-butyl acetate and acetic acid, applied in the field of synthesizing n-butyl acetate, can solve the problems of high production cost, large equipment investment, unavailability, etc., achieves good selectivity and yield, high acetic acid conversion rate, and reduces overall The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

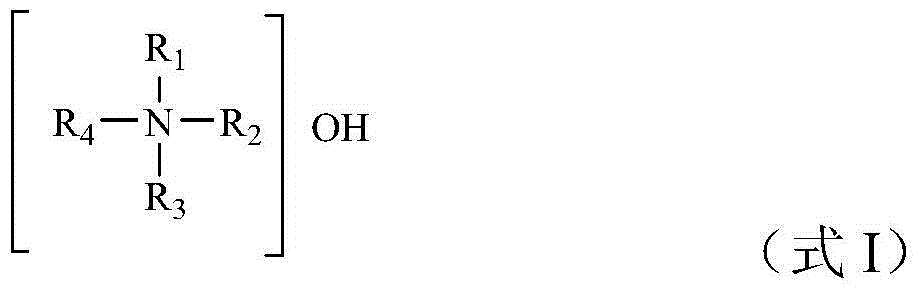

Method used

Image

Examples

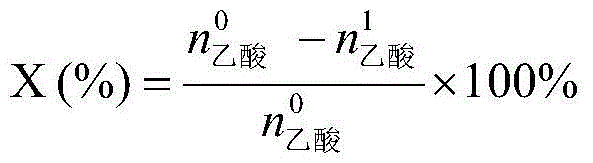

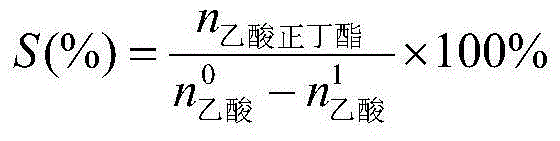

Embodiment 1

[0063] 19.4kg of acetic acid and 44.2kg of n-butanol were added to a dry stainless steel pressure reactor, and then 6.4kg of titanium-silicon molecular sieve TS-1 with a structure-directing agent content of 12.5% by weight in the pores was added to the stainless steel pressure reactor; Reactor sealed, at 200r. min -1 The temperature was raised to 50°C at a certain stirring speed, and the reaction was carried out for 2 hours; after the reaction was completed and the sample was analyzed, the product was transferred to the rectification tower; the final result was that the conversion rate of acetic acid was 99.2%, the selectivity of n-butyl acetate was 99.5%, and the selectivity of n-butyl acetate was 99.5%. The yield of butyl ester was 98.7%.

Embodiment 2

[0067] 11.1kg of acetic acid and 50.6kg of n-butanol were added to a dry stainless steel pressure reactor, and then 6.2kg of titanium-silicon molecular sieve HTS with a hollow structure having a structure directing agent content of 3.0% by weight was added to the stainless steel pressure reactor; The stainless steel high-pressure reactor is sealed, at 300r. min -1 The temperature was raised to 80°C at a certain stirring speed, and the reaction was carried out for 1 hour; after the reaction was completed and the sample was analyzed, the product was transferred to the rectification tower; the final result was that the conversion rate of acetic acid was 99.3%, the selectivity of n-butyl acetate was 99.3%, and the acetic acid The yield of n-butyl ester was 98.6%.

Embodiment 3

[0073] 9.1kg of acetic acid and 52.1kg of n-butanol were added to a dry stainless steel pressure reactor, and then 12.2kg of titanium-silicon molecular sieve HTS with a hollow structure with a structure-directing agent content of 3.0% by weight was added to the stainless steel pressure reactor; the stainless steel The pressure reactor is sealed, at 600r. min -1 The temperature was raised to 150°C at a constant stirring speed, and the reaction was carried out for 0.5h; after the reaction was completed and the sample was analyzed, the product was transferred to the rectification tower; the final result was that the conversion rate of acetic acid was 99.6%, and the selectivity of n-butyl acetate was 95.1%. The yield of n-butyl acetate was 94.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com