Hydrogenated polystyrene-b-styrene/butadiene/isoprene random copolymer as well as preparation method and application thereof

A technology of hydrogenated polystyrene and random copolymers, which is applied in the field of synthesis and application of modified SBIS rubber, can solve the problems of poor UV resistance, low product strength, unsuitable for auto parts and sealing materials, etc. Improvement of aging performance, improvement of green rubber strength, and improvement of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

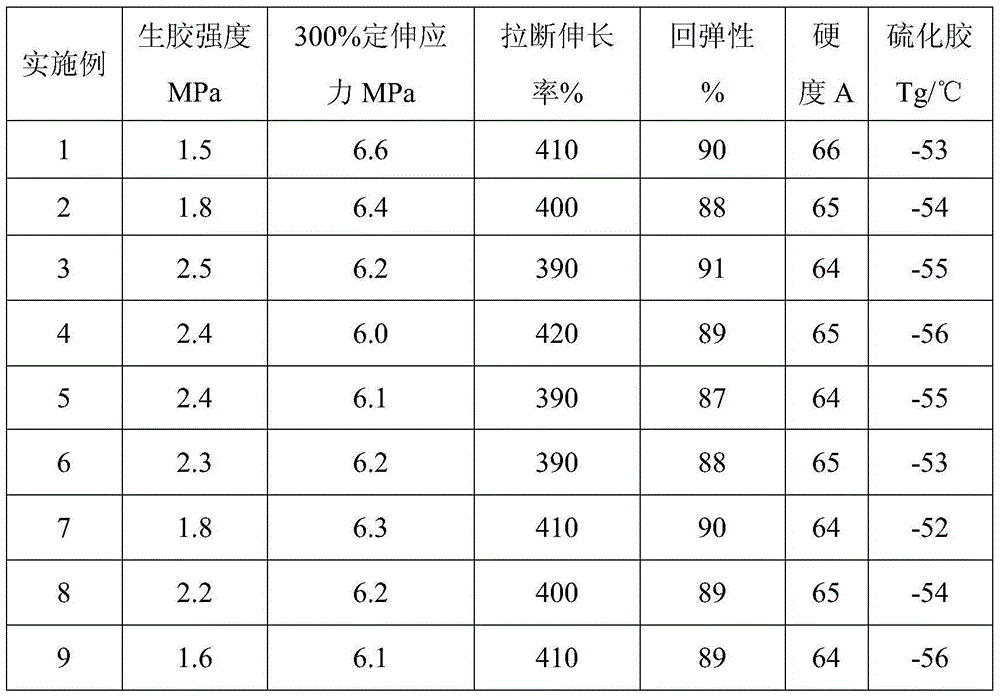

Embodiment 1

[0045] Add 2800mL of cyclohexane solution with 10% n-hexane by mass in a 5-liter polymerization kettle under the protection of nitrogen, then add 2.8mL tetrahydrofuran, heat up to 50-60°C with hot water, and then add 100g of styrene into the polymerization Stir in the still, and then use a syringe to inject 21.5mL of 0.5mol / L n-butyllithium into the polymerization kettle for 20-25min; then add 286.5g of butadiene and 13.5g of isoprene mixed monomer, After reacting at 50-90°C for 20 minutes; then add 10 mL of coupling agent (coupling agent: silicon tetrachloride / methyltrichlorosilane / dimethyldichlorosilane (molar ratio) = 0.1:0.5:0.4, solvent is Cyclohexane, the chlorine concentration is 0.51mol / L), after coupling for 15 minutes, the mass content of vinyl group in the polymer was measured to be 30.53%, the mass content of isopropenyl group was 2.56%, and the number average molecular weight of the coupled polymer was Mn=124000, of which The number-average molecular weight Mn=930...

Embodiment 2

[0047] Add 2800mL of cyclohexane solution with 10% n-hexane in mass parts to a 5-liter polymerization kettle under the protection of nitrogen, then add 5.6mL tetrahydrofuran, heat up to 50-60°C, add 83g styrene into the polymerization kettle and Start stirring, then use a syringe to inject 15.5mL of 0.5mol / L n-butyllithium into the polymerization tank and react for 20min; then add 285g of butadiene, 15.0g of isoprene and 17g of styrene mixed monomer, After reacting at 90°C for 25 minutes, add 10 mL of coupling agent (coupling agent: silicon tetrachloride / methyltrichlorosilane / dimethyldichlorosilane (molar ratio) = 0.3:0.1:0.6, solvent is cyclohexene alkane, chlorine concentration is 0.62mol / L), after coupling for 20min, the mass content of vinyl group in the polymer is 42.20%, the mass content of isopropenyl group is 2.86%, and the number average molecular weight of the coupled polymer is Mn=134000. The number average molecular weight of styrene is Mn=10700, the molecular weig...

Embodiment 3

[0049] Add 2800mL of cyclohexane solution of 10% by mass fraction of n-hexane to a 5-liter polymerization kettle under the protection of nitrogen, then add 5.6mL of tetrahydrofurfuryl alcohol ethyl ether, heat up to 50-60°C, and add 90g of styrene Add it into the polymerization kettle and start stirring, then inject 11mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe and react for 20min; then add 285g of butadiene, 15.0g of isoprene and 10g of styrene mixed monomer , after reacting at 50-90°C for 25 minutes; then add 4.8mL coupling agent (coupling agent: silicon tetrachloride / methyltrichlorosilane / dimethyldichlorosilane (molar ratio)=0.3:0.4:0.3 , the solvent is cyclohexane, and the chlorine concentration is 0.74mol / L). After coupling for 20 minutes, the vinyl mass content in the polymer was measured to be 65.2%, the isopropenyl mass content was 3.21%, and the number average molecular weight of the coupled polymer was Mn=153000 , wherein the number av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com