Method for purifying firefly luciferase

A luciferase, firefly technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

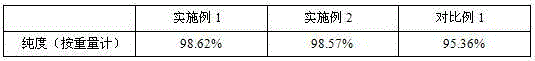

Examples

Embodiment 1

[0029] (1) Take 1L luciferase crude enzyme solution, add 10mmol of magnesium chloride, 15mmol of magnesium sulfate and 16mmol of calcium chloride;

[0030] (2) Add 6g of soybean polysaccharide and 3g of dimercaptothreitol;

[0031] (3) Organic solvent precipitation: slowly add 15ml acetone and 20ml acetonitrile, stir, let stand for 10 minutes, centrifuge at 13000rpm, discard the supernatant, add 10ml Tris-HCl buffer, stir, centrifuge at 13000rpm, collect the supernatant;

[0032] (4) Use a 0.22μm filter membrane for sterile filtration;

[0033] (5) Perform nickel column purification, use pH 7.4 Tris-HCl buffer for column equilibration and elution, and use 20-500mM imidazole for gradient elution during elution;

[0034] (6) Use GE molecular exclusion prepacked column superdex 200 for molecular exclusion, and use pH 7.4 Tris-HCl buffer for column equilibration and elution to obtain 100ml of enzyme solution, which is dried by rotary evaporation;

[0035] The above steps we...

Embodiment 2

[0037] (1) Take 1L luciferase crude enzyme solution, add 20mmol of magnesium nitrate, 12mmol of calcium sulfate, and 8mmol of calcium chloride;

[0038] (2) Add 5g of glycerin;

[0039] (3) Organic solvent precipitation: slowly add 20ml methanol and 12ml acetonitrile, stir, let stand for 10 minutes, centrifuge at 13000rpm, discard the supernatant, add 10ml Tris-HCl buffer, stir, centrifuge at 13000rpm, collect the supernatant;

[0040] (4) Use a 0.22μm filter membrane for sterile filtration;

[0041] (5) Perform nickel column purification, use pH 7.4 Tris-HCl buffer for column equilibration and elution, and use 20-500mM imidazole for gradient elution during elution;

[0042] (6) Use GE molecular exclusion prepacked column superdex 200 for molecular exclusion, and use pH 7.4 Tris-HCl buffer for column equilibration and elution to obtain 100ml of enzyme solution, which is dried by rotary evaporation;

[0043] The above steps (5) and (6) were carried out at 4°C, and other ...

Embodiment 3

[0045] (1) Take 1L luciferase crude enzyme solution, add 30mmol of magnesium chloride, 2mmol of calcium sulfate, 4mmol of calcium chloride and 4mmol of calcium nitrate;

[0046] (2) Add glycerin 8g, ethylene glycol 2g and soybean polysaccharide 5g;

[0047] (3) Organic solvent precipitation: slowly add 30ml of acetonitrile, stir, let stand for 10 minutes, centrifuge at 13000rpm, discard the supernatant, add 10ml Tris-HCl buffer, stir, centrifuge at 13000rpm, collect the supernatant;

[0048] (4) Use a 0.22μm filter membrane for sterile filtration;

[0049] (5) Perform nickel column purification, use pH 7.4 Tris-HCl buffer for column balance and elution, and use 20-500mM imidazole for gradient elution during elution;

[0050] (6) Use GE molecular exclusion prepacked column superdex 200 for molecular exclusion, and use pH 7.4 Tris-HCl buffer for column equilibration and elution to obtain 100ml of enzyme solution, which is dried by rotary evaporation;

[0051] The above st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com