MOCVD (metal organic chemical vapor deposition) capable of monitoring stress in real time

A real-time monitoring and stress technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of photoaging, dislocation generation, device performance degradation, etc., and achieve the effect of improving the signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

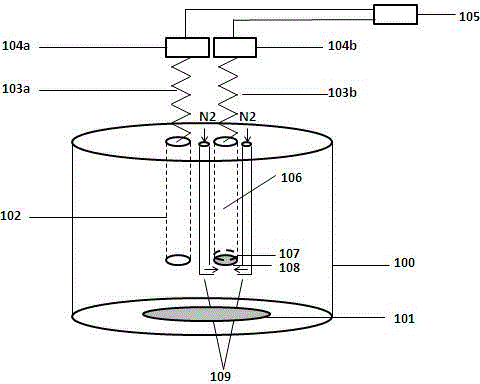

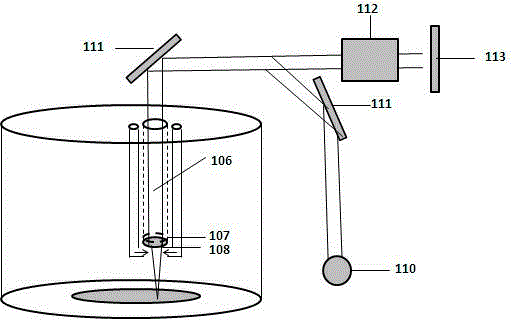

[0019] A kind of MOCVD that can monitor stress in real time proposed by the present invention such as figure 1 with figure 2 As shown, it mainly includes a MOCVD reaction chamber 100, a height-adjustable microscope 102, a stepper motor 103a / b for controlling the height of the Z-axis in the vertical direction, a driver 104a / b for the microscope and a Raman fiber probe, a control computer 105, and real-time Raman fiber optic probe 106 for height adjustment, lens 107 and lens cover 108 of fiber optic probe, nitrogen purge part 109, laser 110 of Raman light source, prism 111 and Raman filter system 112 of Raman test part, CCD 113, etc. , wherein the laser of the Raman light source is Ar+ 488 nm laser, Nd:YAG 532 nm laser or He-Ne 633 nm laser, preferably: He-Ne 633 nm laser.

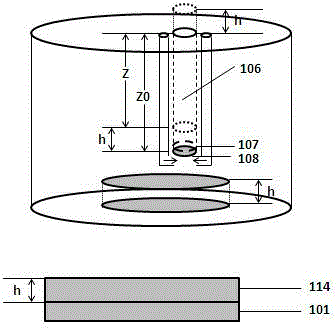

[0020] The MOCVD adjusts the height during the epitaxial growth as image 3 shown. In the method of real-time monitoring of stress in MOCVD, firstly, the Raman fiber probe is corrected for the initial ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com