A current-assisted chemical texturing method for aluminum-doped zinc oxide thin films

A technology of aluminum-doped zinc oxide and thin film, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of insignificant film suede effect, fast etching rate, and difficult control, etc., to improve light trapping ability and photoelectric conversion Efficiency, Enhanced Light Scattering Characteristics, Effects of Improved Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

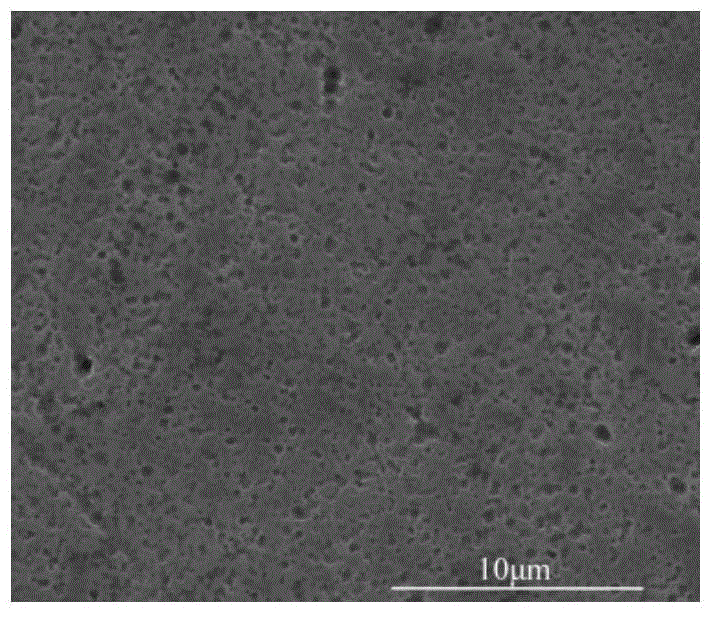

Embodiment 1

[0028] 1. Ultrasonic clean the 30mm×30mm glass substrate in acetone and ethanol for 10 minutes, then soak in 70°C RCA1 and RCA2 solutions for 20 minutes, then clean it with deionized water, and finally dry it with nitrogen. Put the cleaned glass substrate into the magnetron sputtering reaction chamber, preheat it for 60 minutes, pass the argon gas into the reaction chamber as the sputtering atmosphere, control the argon gas flow rate to 12 sccm, and the substrate temperature to 160°C. The injection pressure is 3mTorr, the power is 100W, the aluminum-doped zinc oxide is used as the target material, and the aluminum-doped zinc oxide film is deposited for 6600s to obtain the aluminum-doped zinc oxide film.

[0029] 2. Fix the electrodes at both ends of the deposited aluminum-doped zinc oxide film, immerse the middle part of the aluminum-doped zinc oxide film in the ammonium acetate aqueous solution, and immerse it in the ammonium acetate aqueous solution with a mass fraction of 5%...

Embodiment 2

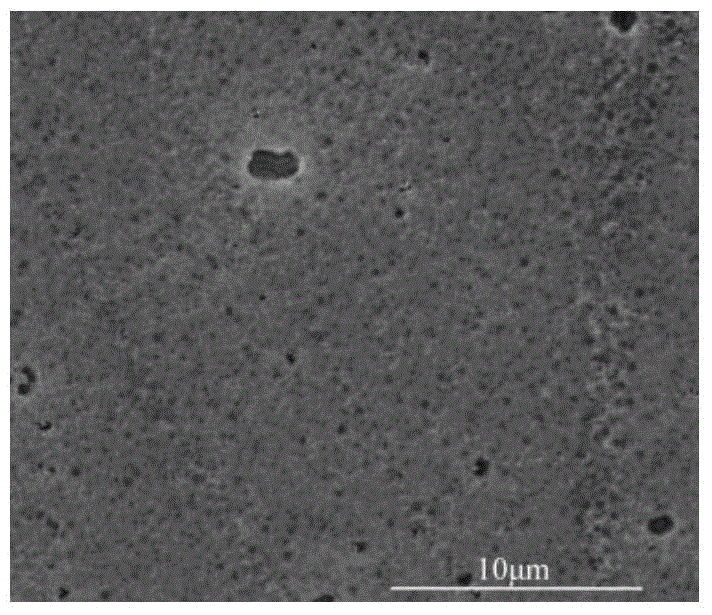

[0033] In the step 2 of the embodiment 1, a current of 50mA is passed through a dual-circuit stabilized voltage and stabilized current power supply, and the other steps are the same as in the embodiment 1 to obtain a suede surface doped aluminum zinc oxide film.

Embodiment 3

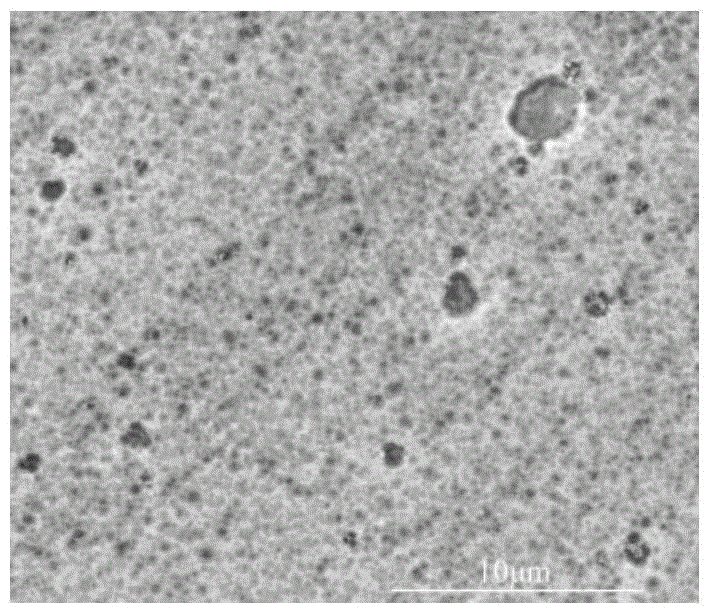

[0035] In the step 2 of the embodiment 1, a 100mA current was passed through a two-way regulated voltage and current power supply, and the other steps were the same as in the embodiment 1 to obtain a textured aluminum-doped zinc oxide film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com