Forward permeable membrane cleaning agent and method for applying same

A technology of forward osmosis membrane and cleaning agent, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of FO membrane system fouling, membrane flux decline, membrane fouling, etc. Good stability and enhanced cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of cleaning agent

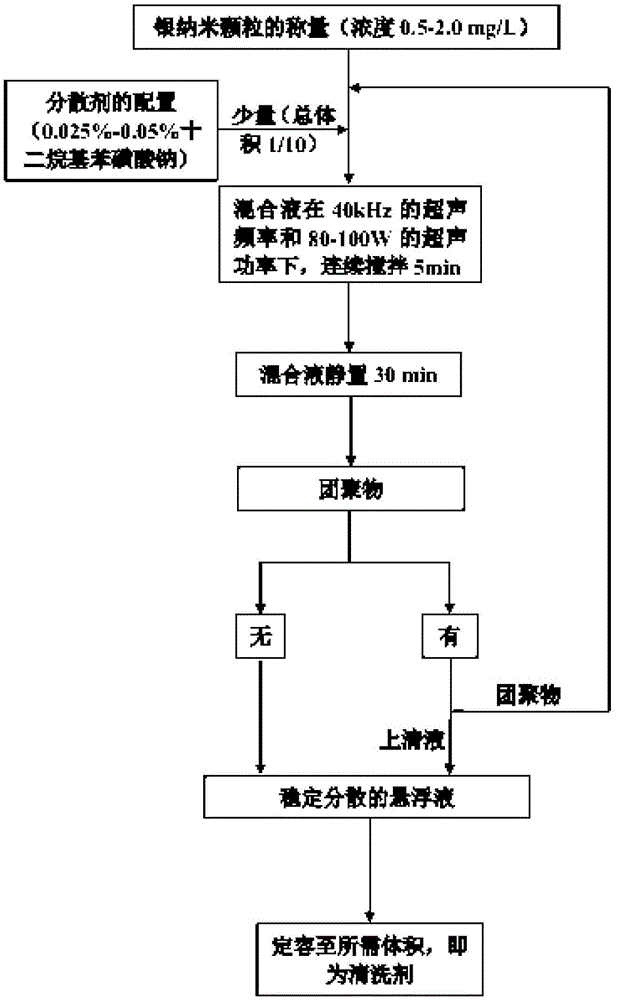

[0034] use figure 1 The configuration process for preparing forward osmosis membrane cleaning agent.

[0035] (1) Dispersant configuration: configure a sodium dodecylbenzenesulfonate solution with a mass fraction of 0.025%;

[0036] (2) Accurately take by weighing a certain amount of silver nanoparticles of 20-40nm, place in the container, add a small amount of above-mentioned dispersant;

[0037] (3) Stir the above solution continuously for 5 minutes under ultrasound (40kHz, 80-100W), and transfer the supernatant to the container after standing for 30 minutes; continue to add a small amount of the above dispersant, stir with ultrasound for 5 minutes, let stand for 30 minutes, transfer Supernatant: Repeat this operation until there is no agglomerated silver nanoparticles after standing still for 30 minutes, then the volume can be adjusted to 0.5-2.0 mg / L silver nanoparticle suspension.

[0038] Surfactant SDBS is very...

Embodiment 2

[0039] Embodiment 2: the preparation of cleaning agent

[0040] The preparation process of forward osmosis membrane cleaning agent is as follows:

[0041](1) Dispersant configuration: configure a sodium dodecylbenzenesulfonate solution with a mass fraction of 0.05%;

[0042] (2) Accurately take by weighing a certain amount of silver nanoparticles of 20-40nm, place in the container, add a small amount of above-mentioned dispersant;

[0043] (3) Continuously stir the above solution under ultrasonic waves, then let it stand still, and transfer the supernatant; continue to add a small amount of the above-mentioned dispersant, stir it with ultrasonic waves, let it stand, and transfer the supernatant; repeat this operation until no The agglomerated silver nanoparticles can be fixed to volume and configured into a 0.5-2.0mg / L silver nanoparticle suspension.

[0044] The preparation method of the present invention adopts the method of multiple times of ultrasonication, standing stil...

Embodiment 3

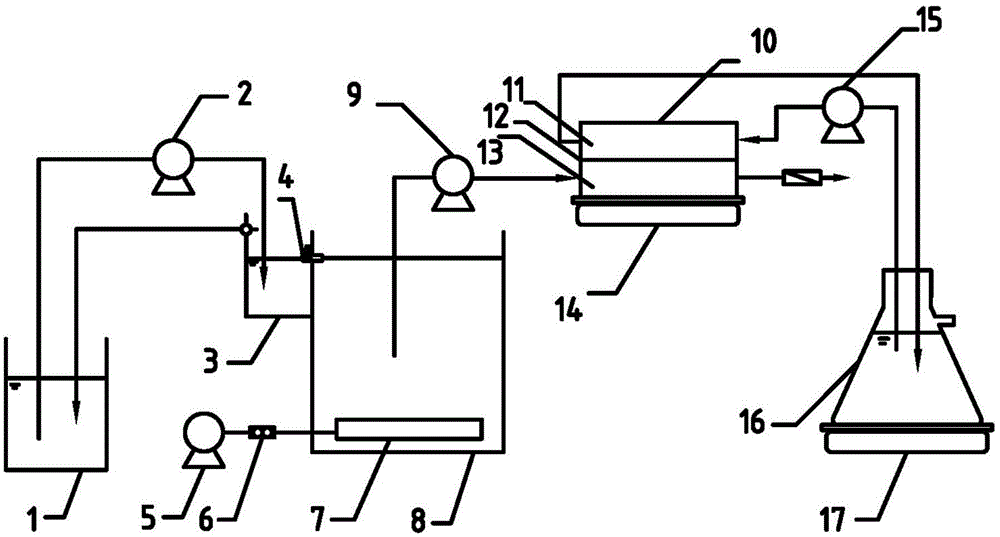

[0045] Embodiment 3: the application of cleaning agent

[0046] Get the heavily polluted forward osmosis membrane in the OMBR reactor, a large amount of organic and microbial pollutants are deposited on the surface of the polluted forward osmosis membrane, and its pure water flux is only 3.62LMH (drawing solution 1.0MNaCl, cross-flow velocity 0.13m / s, measured at a temperature of 26°C). First, replace the drawing solution with deionized water, and perform a simple backwash. After continuous flushing for 1 hour, the membrane flux returns to 6.3LMH; then, replace the deionized water with the cleaning agent - 1.0mg / L silver nanometer The particle suspension (containing 0.05% sodium dodecylbenzenesulfonate), after continuous operation for 1 hour, the flux can be recovered to 8.57LMH, which is 84.62% of the new membrane flux.

[0047] Under the same conditions, using 0.5mg / L silver nanoparticle suspension (containing 0.025% sodium dodecylbenzenesulfonate) as a cleaning agent, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com