A kind of preparation method of graphene/hydroxyapatite composite material

A technology of hydroxyapatite and composite materials, which is applied in graphene, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of large hydroxyapatite crystal particles, reduced hardness of composite materials, and complicated manufacturing process. , to achieve the effect of easy mass production, saving raw material cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

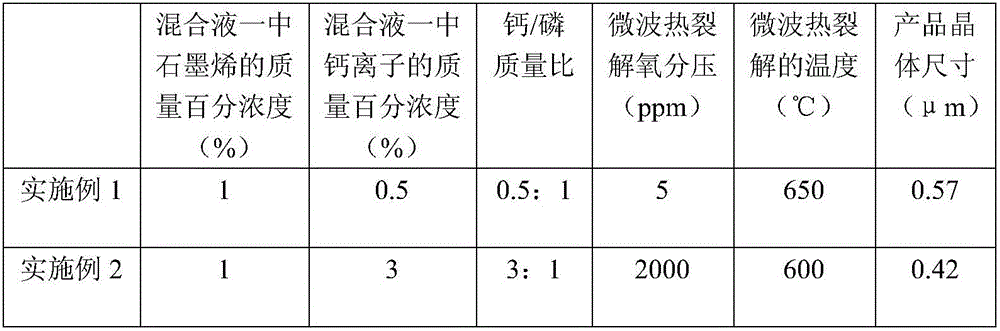

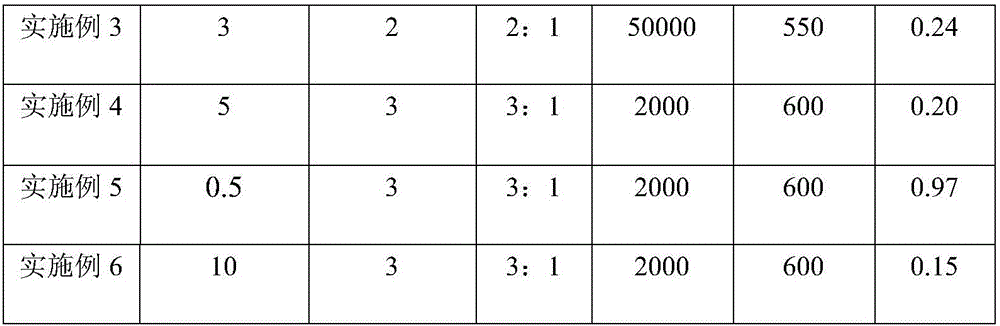

[0022] A preparation method of graphene / hydroxyapatite composite material, comprising the following steps:

[0023] (1) Graphene solution is mixed with the calcium salt solution containing calcium ion to obtain mixed solution one, the mass percent concentration of graphene in mixed solution one is 0.5~10%, the mass percent concentration of calcium ion is 0.5~3 %;

[0024] (2) preparing a phosphate solution, and according to the mass ratio of the calcium in the mixed solution 1 and the phosphorus in the phosphate solution being 0.5~3: 1, adding the phosphate solution to the mixed solution 1, mixing to obtain the mixed solution 2;

[0025] (3) Use an ultrasonic oscillator atomizer with an ultrasonic power of 1000-1200w and a transducer frequency of 5-7MHz to atomize the mixed liquid 2, and set the temperature of the atomized airflow at 550-650°C, The oxygen partial pressure is 5~10000ppm microwave pyrolysis equipment cavity, carry out pyrolysis, after reacting for 10 minutes, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com