Graphene organic functional modification methods and application

A graphene and functionalization technology, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as poor compatibility between organic groups and metal lithium, low conductivity of polymer electrolytes, and impact on use value. Achieve high electrical conductivity, good mechanical properties, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

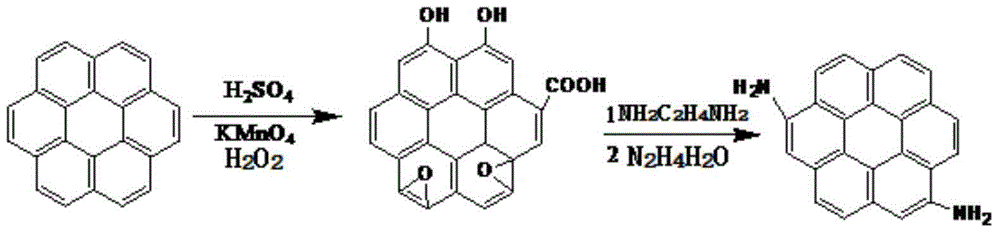

[0023] The present embodiment provides a kind of modified graphene, and it is prepared by following steps:

[0024] S1. Using the classic Hummers method, in a 500ml four-necked flask with stirring and a thermometer, mix 10g of graphite powder and 4g of anhydrous sodium nitrate and add 100ml of concentrated H 2 SO 4 , and stirred for 0.5h under ice bath conditions, under strong stirring, adding 10gKMnO 4 , react at 0°C for 4h, and use 3% volume concentration of H 2 o 2 Reduction of excess KMnO 4 and some KMnO 4 The reduced MnO 2 , so that the two become colorless and soluble MnSO 4 , and finally obtain a bright yellow suspension, which is filtered, washed and vacuum dehydrated to obtain graphene oxide;

[0025] S2, adding 10 g of the graphene oxide to 200 g of NMP, ultrasonic treatment for 2 h, adding 1 g of ethylenediamine to the NMP solution of graphene oxide, and stirring and reacting at 80° C. for 4 h to obtain functionalized graphene oxide;

[0026] S3, add 10g N i...

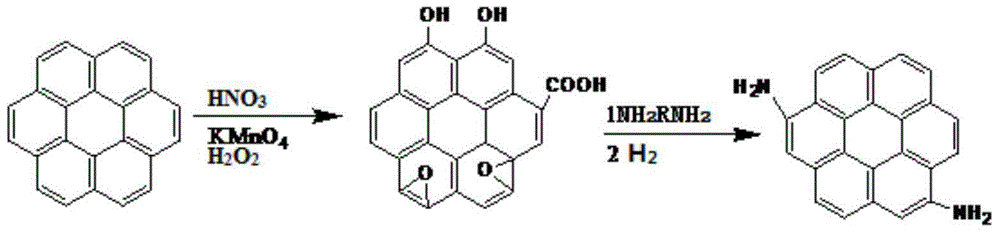

Embodiment 2

[0030] S1. Using the classic Hummers method, in a 500ml four-neck flask with stirring and a thermometer, mix 15g of graphite powder and 8g of anhydrous sodium nitrate and add 150ml of concentrated HNO 3 , and stirred for 1 h under ice bath conditions, under vigorous stirring, added 12g KMnO 4 , react at 2°C for 5h, and use 4% volume concentration of H 2 o 2 Reduction of excess KMnO 4 and some KMnO 4 The reduced MnO 2 , so that the two become colorless and soluble MnSO 4 , to finally obtain a bright yellow suspension, which is filtered, washed and vacuum dehydrated to obtain graphene oxide;

[0031] S2. Add 13 g of the graphene oxide to 300 g of NMP, ultrasonically treat it for 2.5 h, add 1 g of hexamethylenediamine and 1 g of dicyclohexylcarbodiimide to the NMP solution of graphene oxide, and stir the reaction at 85° C. 4.5h, obtain functionalized graphene oxide;

[0032] S3, and then into the reducing agent H 2 , the temperature was raised to 95° C., the reduction rea...

Embodiment 3

[0036] S1. Using the classic Hunmers method, in a 500ml four-neck flask with stirring and a thermometer, mix 20g of graphite powder and 10g of anhydrous sodium nitrate into 250ml of concentrated HCl, and stir for 2 hours under ice bath conditions, then vigorously stir Next, add 15gKMnO 4 , react at 2°C for 5h, and use 5% volume concentration of H 2 o 2 Reduction of excess KMnO 4 and some KMnO 4 The reduced MnO 2 , making it into colorless and soluble MnSO 4 , and finally obtain a bright yellow suspension, which is filtered, washed and vacuum dehydrated to obtain graphene oxide;

[0037] S2, adding 13g of the graphene oxide to 300g of NMP, ultrasonic treatment for 2.5h, adding 2g of butanediamine and 2g of hexamethylenediamine to the NMP solution of graphene oxide, and stirring and reacting at 85°C for 4.5h to obtain Functionalized graphene oxide;

[0038] S3, adding 15g NaBH to the functionalized graphene oxide 4 , the temperature was raised to 95° C., the reduction reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com