Tri-functionality quaternary ammonium salt epoxy (methyl) acrylate monomer, and preparation method thereof

A trifunctional, acrylate technology, applied in the preparation of aminohydroxy compounds, chemical instruments and methods, preparation of organic compounds, etc. Good effect, increased potential for the treatment of caries, good plasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

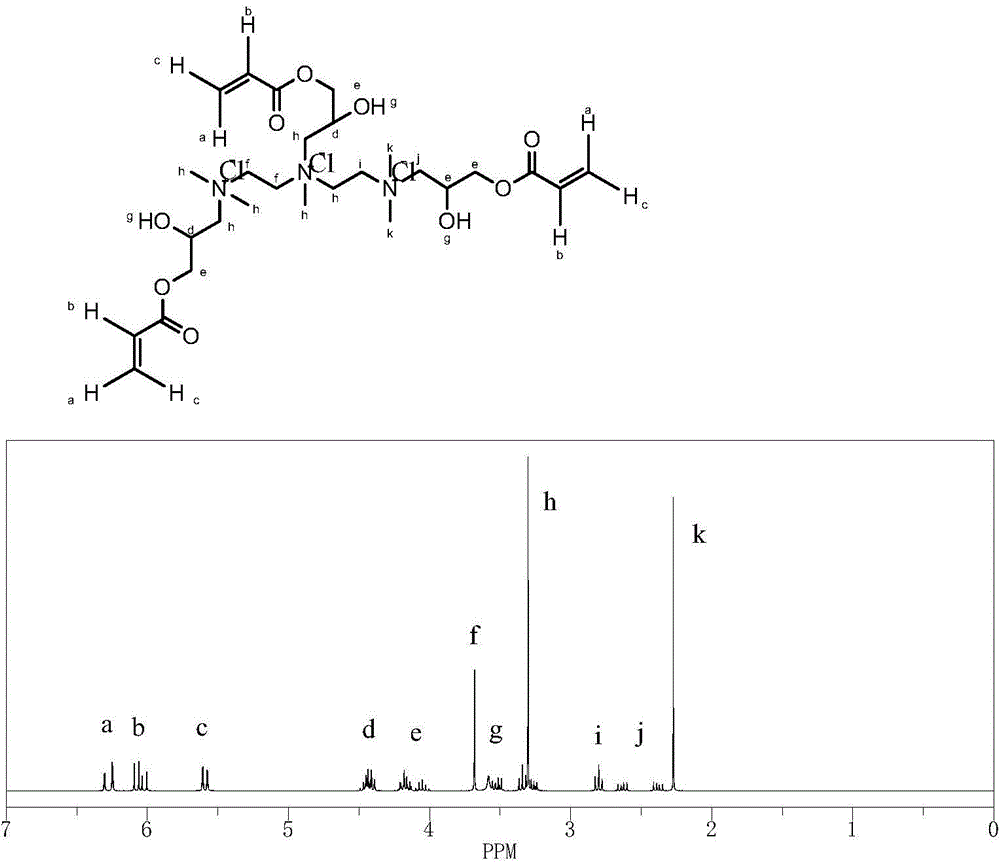

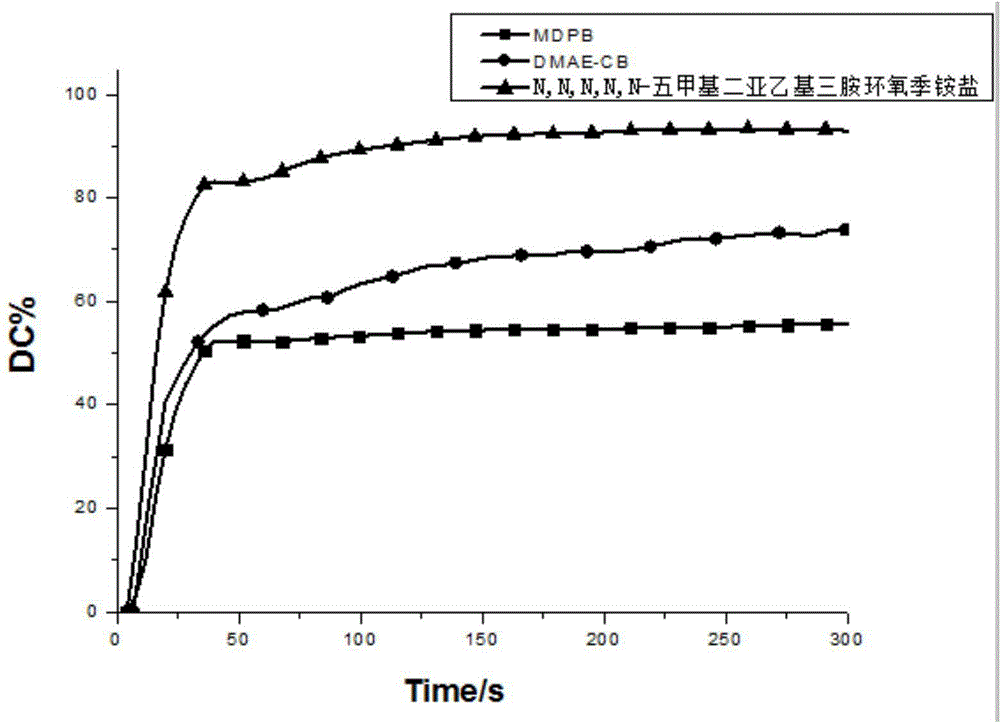

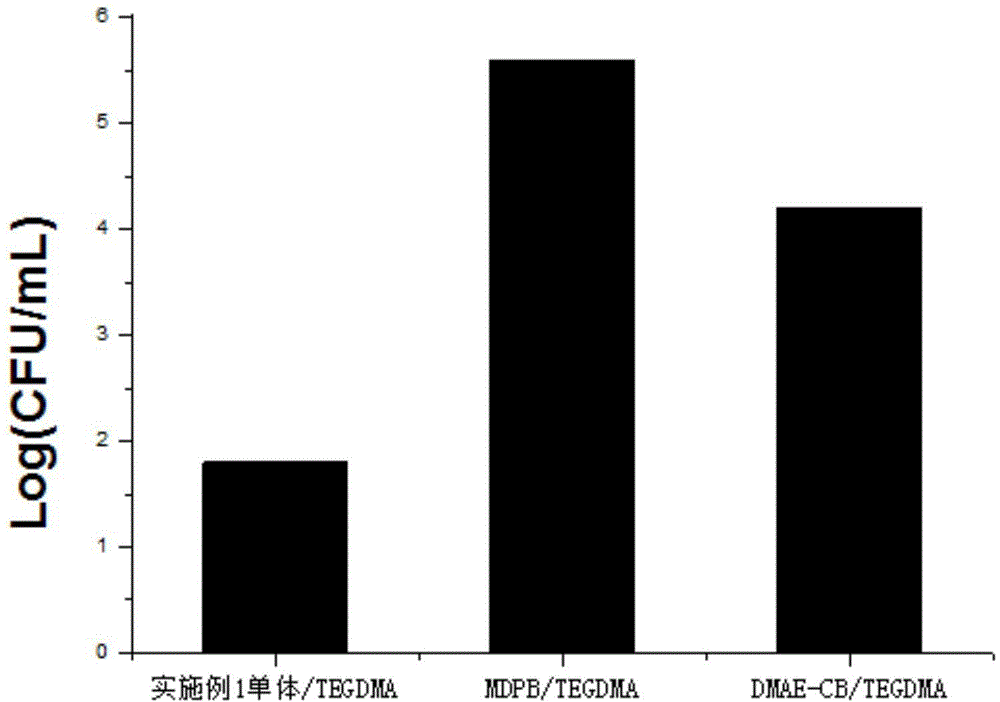

[0027] Step 1: Preparation of N,N,N,N,N-pentamethyldiethylenetriamine epoxy quaternary ammonium salt

[0028] Add 0.3mol epichlorohydrin and 1,4-dioxane to a two-necked flask equipped with a magneton for dilution, and add 0.1mol N,N,N,N,N-pentamethyl dropwise while stirring in an ice-water bath A mixture of diethylenetriamine and 1,4-dioxane. Finish dripping within 1h. Continue to react for 5h after dropping. Immediately after the reaction was completed, it was suction filtered, washed with a solvent, and vacuum-dried to obtain white crystals of epoxy quaternary ammonium salt.

[0029] Step 2: Trifunctional quaternary ammonium salt epoxy (meth)acrylate monomer

[0030] Add 0.1mol epoxy quaternary ammonium salt, cyclohexane and 2wt% hydroquinone into a three-necked flask equipped with magnetons. The temperature was raised to 80° C., and 0.3 mol of methacrylic acid was continuously added dropwise through a constant pressure dropping funnel under stirring. After the dropwise...

Embodiment 2

[0032] Step 1: Preparation of N,N,N,N,N-pentaethyldiethylenetriamine epoxy quaternary ammonium salt

[0033] Add 0.6mol epichlorohydrin and anhydrous ether to a two-necked flask equipped with magnets for dilution, and add 0.1mol N,N,N,N,N-pentaethyldiethylene dropwise while stirring in an ice-water bath A mixture of triamine and anhydrous ether. Finished dripping within 1.5h. Continue to react for 4h after dropping. Immediately after the reaction was completed, it was suction filtered, washed with a solvent, and vacuum-dried to obtain white crystals of epoxy quaternary ammonium salt.

[0034] Step 2: Preparation of trifunctional quaternary ammonium salt epoxy (meth)acrylate monomer

[0035] Add 0.1mol of epoxy quaternary ammonium salt, toluene and 2wt% p-hydroxyanisole in a three-necked flask equipped with a magneton. The temperature was raised to 85° C., and 0.3 mol of methacrylic acid was continuously added dropwise through a constant pressure dropping funnel under stirr...

Embodiment 3

[0037] Step 1: Preparation of N,N,N,N,N-pentapropyldiethylenetriamine epoxy quaternary ammonium salt

[0038] Add 0.6mol epichlorohydrin and tetrahydrofuran to a two-necked flask equipped with magnets for dilution, and add 0.1mol N,N,N,N,N-pentapropyldiethylenetriamine dropwise while stirring in an ice-water bath and tetrahydrofuran mixture. Finish dripping within 2h. Continue to react for 3h after dropping. Immediately after the reaction was completed, it was suction filtered, washed with a solvent, and vacuum-dried to obtain white crystals of epoxy quaternary ammonium salt.

[0039] Step 2: Preparation of trifunctional quaternary ammonium salt epoxy (meth)acrylate monomer

[0040]Add 0.1mol of epoxy quaternary ammonium salt, cyclohexanone and 2wt% methyl hydroquinone into a three-necked flask equipped with magnetons. The temperature was raised to 90° C., and 0.3 mol of methacrylic acid was continuously added dropwise through a constant pressure dropping funnel under stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com