Fiber-reactive aqueous fracturing fluid for compact reservoir transformation, and use method thereof

A technology for tight reservoirs and hydraulic fracturing, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high construction friction, low fluid loss, and increased viscosity, and achieve less residue and lower friction. resistance, reducing the effect of clay swelling and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

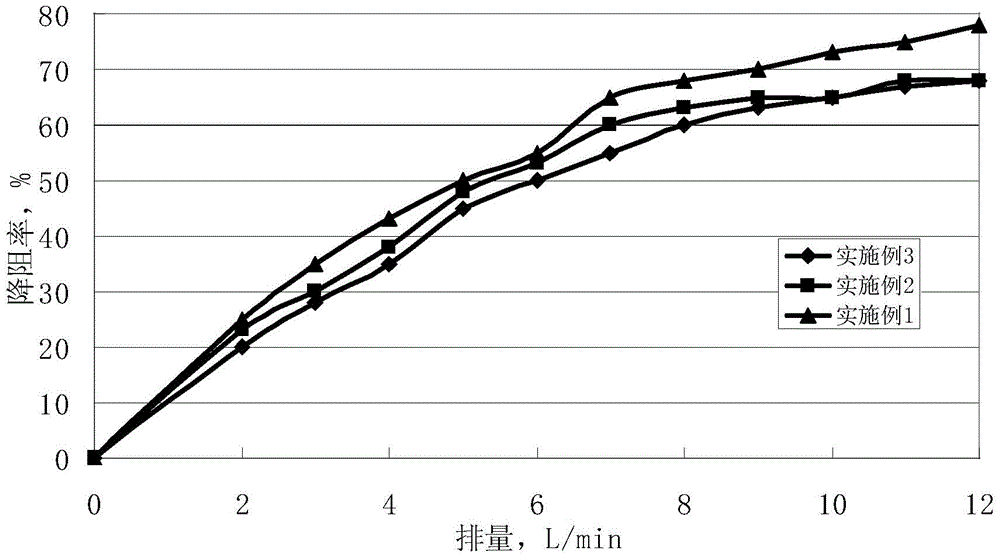

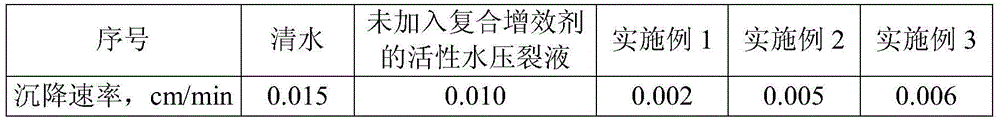

Embodiment 1

[0026] This embodiment provides a fiber-activated water fracturing fluid for tight reservoir reconstruction. In terms of weight percentage, its raw material composition includes: 0.1% of drag reducing agent, 1.2% of composite synergist, 0.3% of water-soluble fiber and water balance. Wherein, the drag reducing agent is composed of 0.05% (based on the total weight of the fiber-activated water fracturing fluid) of seaweed gum and 0.05% of locust bean gum. Based on the total weight of the composite synergist, it consists of 20% isopropanol, 20% octadecylpyridine chloride, 5% alkylphenol polyoxyethylene polymethyloxyethylene ether, alkylphenol polyoxyethylene 5% of oxyethylene ether, 15% of cetyltrimethylammonium bromide, 5% of dodecylbenzyldimethylammonium chloride, 10% of potassium chloride and the balance of water, the compound synergistic The agent is prepared by mixing the raw materials and fully stirring them evenly. The water-soluble fiber is composed of polyacrylonitrile ...

Embodiment 2

[0028] This example provides a fiber-activated water fracturing fluid for tight reservoir reconstruction. In terms of weight percentage, its raw material composition includes: drag reducing agent 0.08%, composite synergist 1.0%, water-soluble fiber 0.2% and water balance. Wherein, the drag reducing agent is konjac gum. Based on the total weight of the composite synergist, it consists of 30% ethanol, 10% cetylpyridinium chloride, 10% fatty alcohol polyoxyethylene ether, dodecylbenzyltrimethylammonium chloride 20%, octadecyltrimethylammonium bromide 5%, potassium chloride 20% and the balance of water. The composite synergist is prepared by mixing the raw materials and fully stirring them uniformly. The water-soluble fiber is polyacrylonitrile fiber; the performance parameters of the polyacrylonitrile fiber are: the tensile strength of the fiber is 159MPa, and the true density of the fiber is 0.998g / cm 3 , with a fiber length of 5 mm and a fiber diameter of 75 μm.

Embodiment 3

[0030]This example provides a fiber-activated water fracturing fluid for tight reservoir reconstruction. In terms of weight percentage, its raw material composition includes: drag reducing agent 0.05%, composite synergist 0.5%, water-soluble fiber 0.1% and water balance. Wherein, the drag reducing agent is gum arabic. Based on the total weight of the composite synergist, it consists of 30% ethanol, 10% cetylpyridinium chloride, 10% fatty alcohol polyoxyethylene ether, dodecylbenzyltrimethylammonium chloride 20%, octadecyltrimethylammonium bromide 5%, potassium chloride 20% and the balance of water. The composite synergist is prepared by mixing the raw materials and fully stirring them uniformly. The water-soluble fiber is polyethylene fiber and polyvinyl alcohol fiber; the performance parameters of the polyethylene fiber are: the tensile strength of the fiber is 75MPa, and the real density of the fiber is 0.985g / cm 3 , the fiber length is 3 mm, and the fiber diameter is 88 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com