ITO film etching solution for liquid crystal panel manufacturing process and preparation method thereof

A manufacturing process and liquid crystal panel technology, applied in the direction of surface etching compositions, chemical instruments and methods, etc., can solve the problems of microcrystal residue, high transportation cost, easy crystallization, etc., to avoid unclean etching and improve etching effect , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

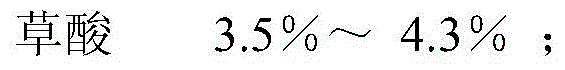

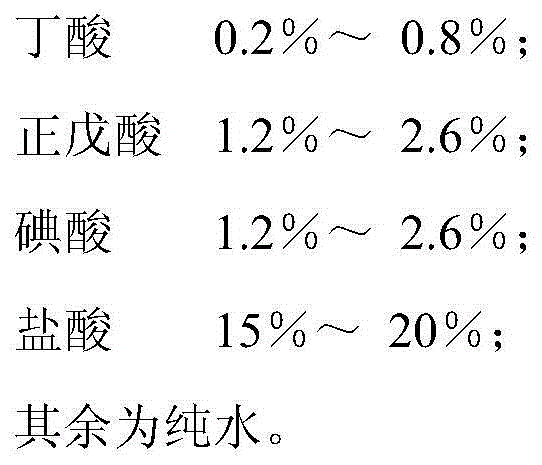

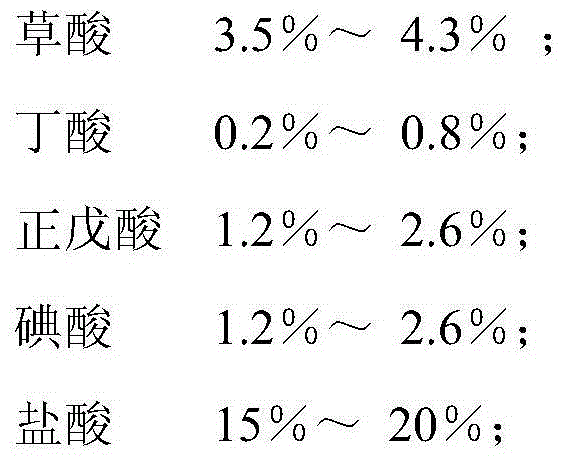

[0018] Embodiment 1, the present invention is a kind of ITO film etchant in liquid crystal panel manufacturing process, and it comprises the composition of following percentage by weight: oxalic acid 3.5%; Butyric acid 0.2%; N-valeric acid 1.2%; Iodic acid 1.2%; Hydrochloric acid 15%; the rest is pure water. Wherein, oxalic acid is the oxalic acid crystal of concentration greater than 99.5% (percentage by weight), the concentration of butyric acid is greater than 99.5% (percentage by weight), the concentration of n-valeric acid is greater than 89% (percentage by weight), and the concentration of iodic acid is greater than 79% (percentage by weight) Percent), the concentration of hydrochloric acid is greater than 55% (percentage by weight).

[0019] Taking the ITO film etching solution in the above liquid crystal panel manufacturing process as an example, the preparation process steps are as follows:

[0020] The first step: add the strong acidic cation exchange resin to hydro...

Embodiment 2

[0027] Embodiment 2, the present invention is a kind of ITO film etchant in liquid crystal panel manufacturing process, and it comprises the composition of following percentage by weight: oxalic acid 3.8%; Butyric acid 0.4%; N-valeric acid 1.6%; Iodic acid 1.6%; Hydrochloric acid 16%; the rest is pure water. Wherein, oxalic acid is oxalic acid crystal with a concentration greater than 99.5%, the concentration of butyric acid is greater than 99.5%, the concentration of n-valeric acid is greater than 89%, the concentration of iodic acid is greater than 79%, and the concentration of hydrochloric acid is greater than 55%.

[0028] Taking the ITO film etching solution in the above liquid crystal panel manufacturing process as an example, the preparation process steps are as follows:

[0029] The first step: add the strong acidic cation exchange resin to hydrochloric acid, stir and mix, the stirring speed is 65 rpm, and the stirring time is 8 minutes, then filter out the strong acid...

Embodiment 3

[0036] Embodiment 3, the present invention is a kind of ITO film etchant in liquid crystal panel manufacturing process, and it comprises the composition of following percentage by weight: oxalic acid 4.0%; Butyric acid 0.5%; N-valeric acid 2.0%; Iodic acid 2.0%; Hydrochloric acid 17%; the rest is pure water. Wherein, oxalic acid is oxalic acid crystal with a concentration greater than 99.5%, the concentration of butyric acid is greater than 99.5%, the concentration of n-valeric acid is greater than 89%, the concentration of iodic acid is greater than 79%, and the concentration of hydrochloric acid is greater than 55%.

[0037] Taking the ITO film etching solution in the above liquid crystal panel manufacturing process as an example, the preparation process steps are as follows:

[0038] The first step: add the strong acidic cation exchange resin to hydrochloric acid, stir and mix, the stirring speed is 68 rpm, and the stirring time is 8 minutes, then filter out the strong acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com