Industrialized treatment method for deleading slag generated by pyrogenic-process antimony smelting

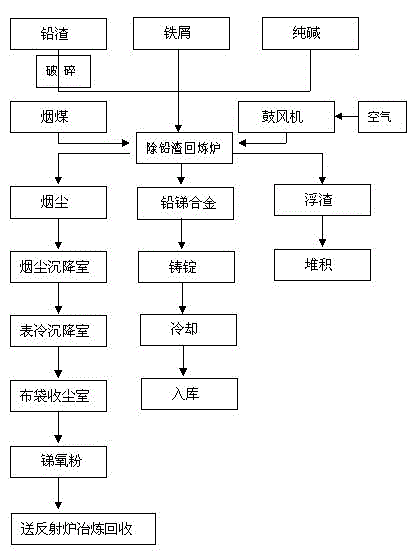

A technology for removing lead slag and smelting antimony, which is applied in the field of pyrotechnic antimony smelting, and achieves the effects of easy handling, improved melting and reduction reaction capabilities, and fast heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

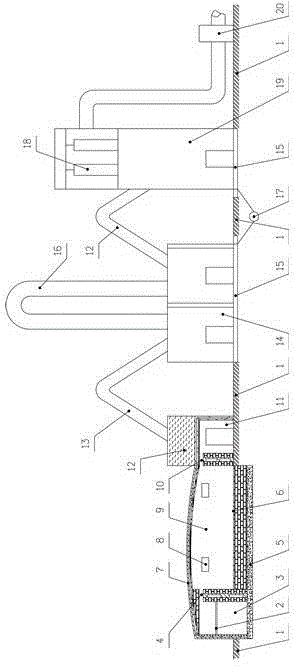

[0023] A method for carrying out industrialized treatment of lead-removing slag produced by pyrometallurgy, comprising the following steps:

[0024] (1) Selection of raw and auxiliary materials: A. The deleading slag is the deleading slag produced by using phosphate refining to remove lead during the reduction smelting process of the reverberatory furnace. The antimony content in the deleading slag is 15%, and the lead content is 3%. Iron filing wire with a diameter of 20cm is selected, C is alkali, soda ash is selected, and the mass fraction of sodium carbonate in soda ash is 95%; D, bituminous coal is selected from high-quality bituminous coal with a particle size of 25mm, the mass fraction of fixed carbon in bituminous coal is 55%, and the ash content is 15% %, the moisture content is 4%;

[0025] (2) Raw material pretreatment: crush the lead removal slag to particles with a diameter of 60mm;

[0026] (3) Melting and reduction: Add 4000kg of raw materials for removing lead...

Embodiment 2

[0033] A method for carrying out industrialized treatment of lead-removing slag produced by pyrometallurgy, comprising the following steps:

[0034] (1) Selection of raw and auxiliary materials: A. The deleading slag is the deleading slag produced by using phosphate refining to remove lead during the reduction smelting process of the reverberatory furnace. The antimony content in the deleading slag is 30%, and the lead content is 10%. Iron filing wire with a diameter of 3cm is selected, soda ash is selected as base C, and the mass fraction of sodium carbonate in soda ash is 96%; high-quality bituminous coal with a particle size of 15mm is selected for D bituminous coal, and the mass fraction of fixed carbon in bituminous coal is 60%. is 20%, moisture content is 6%;

[0035] (2) Raw material pretreatment: crush the lead removal slag into particles with a diameter of 80mm;

[0036] (3) Melting and reduction: Add 3000kg of lead slag removal charge after pretreatment in step (2) ...

Embodiment 3

[0040] A method for carrying out industrialized treatment of lead-removing slag produced by pyrometallurgy, comprising the following steps:

[0041] (1) Selection of raw and auxiliary materials: A. The deleading slag is the deleading slag produced by using phosphate refining to remove lead during the reduction smelting process of the reverberatory furnace. The antimony content in the deleading slag is 20%, and the lead content is 5%. Shavings select the iron filing wire that diameter is 10cm for use, and all the other are the same as embodiment 1.

[0042] (2) Raw material pretreatment: same as embodiment 1.

[0043] (3) Melting and reduction: Add 3000kg of lead slag removal charge after pretreatment in step (2) into the furnace pool of the lead removal slag recycling furnace, and the two sides of the furnace pool of the lead removal slag recycling furnace are respectively There are 2 furnace doors, and then high-quality bituminous coal is added into the combustion chamber, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com