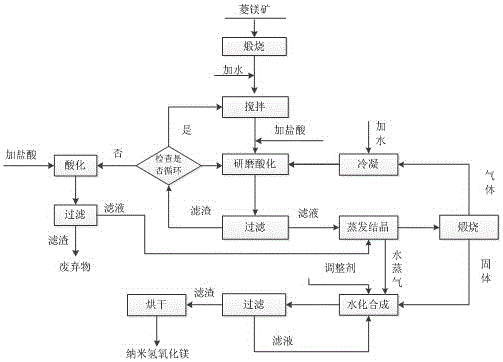

Method for preparing flaky monodisperse nano-magnesium hydroxide from magnesite

A nano-magnesium hydroxide and magnesite technology, applied in the field of mineral processing, can solve the problems of affecting the chroma of magnesium hydroxide, low flame retardant grade magnesium hydroxide, and can only reach the micron level, etc., to shorten the hydration time, Reduced acidification time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step: magnesite calcined water-soluble

[0029] Crush the magnesite to less than 9mm, and then calcining after crushing, the calcining temperature is 630°C, and the calcining time is 3 hours to obtain magnesium oxide powder, weigh 28g of magnesium oxide powder, add it to the stirring tank, and add 18ml of water, stir for 0.3min.

[0030] The second step: Grinding and acidifying magnesium oxide powder slurry

[0031] Transfer the stirred magnesium oxide powder slurry to an acidified stirring mill for grinding. After grinding for 2 minutes, add hydrochloric acid to the acidified stirring mill to acidify the magnesium oxide powder. The acidification time is 1 minute, and the magnesium oxide powder slurry is added from the bottom to acidify In the stirred mill, hydrochloric acid is added into the acidified stirred mill from the middle, and the acidified slurry is discharged from the upper end of the acidified stirred mill.

[0032] The third step: Acidification ...

Embodiment 2

[0042] The first step: calcination of magnesite

[0043] Same as the first step of Example 1.

[0044] The second step: Grinding and acidifying magnesium oxide powder slurry

[0045] Same as the second step of Example 1.

[0046] The third step: Acidification and impurity removal of magnesium oxide powder slurry

[0047] During the acidification process, add 140ml of hydrochloric acid with a mass percentage concentration of 23% from the middle to acidify the magnesium oxide powder. This process requires insufficient hydrochloric acid and excessive magnesium oxide powder. Brown-red precipitates appear in the slurry and are discharged from the upper end of the acidification stirring mill. The slurry is filtered to obtain filtrate and filter residue, impurities such as iron, manganese, calcium and excessive magnesium oxide powder enter the solid filter residue, and the filtrate is the magnesium chloride solution after impurity removal.

[0048] Step Four: Preparation of Activa...

Embodiment 3

[0056] The first step: calcination of magnesite

[0057] Same as the first step of Example 1.

[0058] The second step: Grinding and acidifying magnesium oxide powder slurry

[0059] Same as the second step of Example 1.

[0060] The third step: Acidification and impurity removal of magnesium oxide powder slurry

[0061] During the acidification process, add 149ml of hydrochloric acid with a mass percentage concentration of 21.5% from the middle to acidify the magnesium oxide powder. This process requires insufficient hydrochloric acid and excessive magnesium oxide powder. Brown-red precipitates appear in the slurry and are discharged from the upper end of the acidification stirring mill. The slurry is filtered to obtain filtrate and filter residue, impurities such as iron, manganese, calcium and excessive magnesium oxide powder enter the solid filter residue, and the filtrate is the magnesium chloride solution after impurity removal.

[0062] Step Four: Preparation of Acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com