Multi-walled carbon nano-tube supported manganese oxide-based catalyst preparation method

A multi-walled carbon nanotube, manganese oxide-based technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low conversion rate and duration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

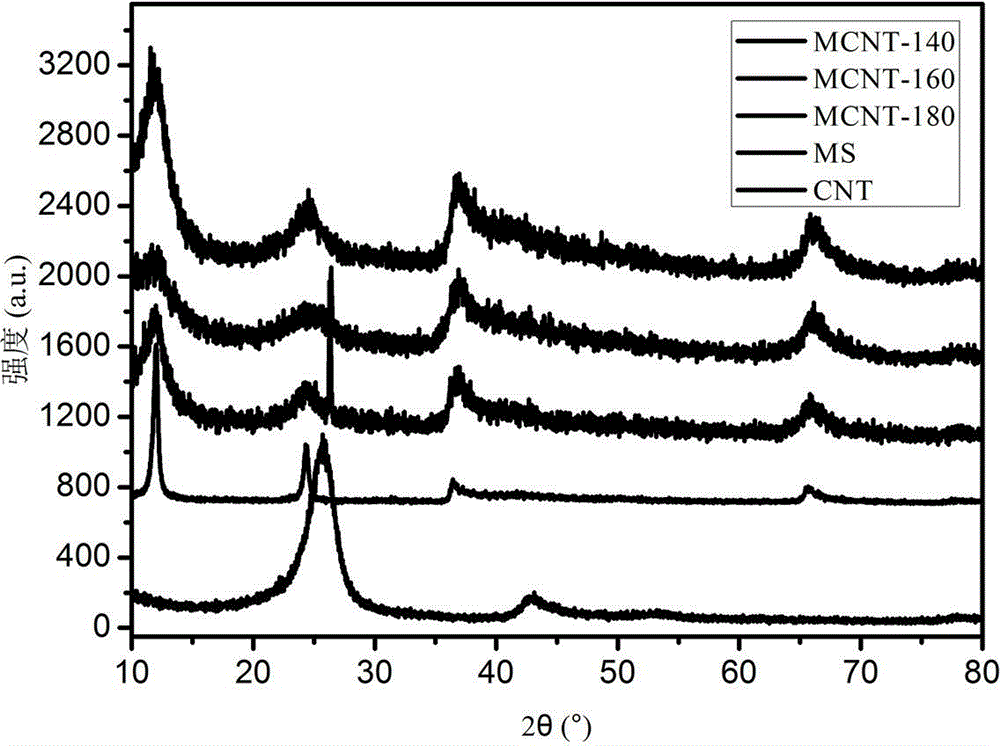

[0017] 7g potassium permanganate (KMnO 4 ) was dissolved in 150ml of deionized water, and 5ml of concentrated sulfuric acid (95wt%) was added dropwise into the potassium permanganate solution with constant stirring. The reaction temperature was 160°C for 40 minutes, vacuum filtration, washing with a large amount of water, and drying in an oven at 60°C to obtain a non-supported manganese oxide-based catalyst, denoted as MS.

Embodiment 2

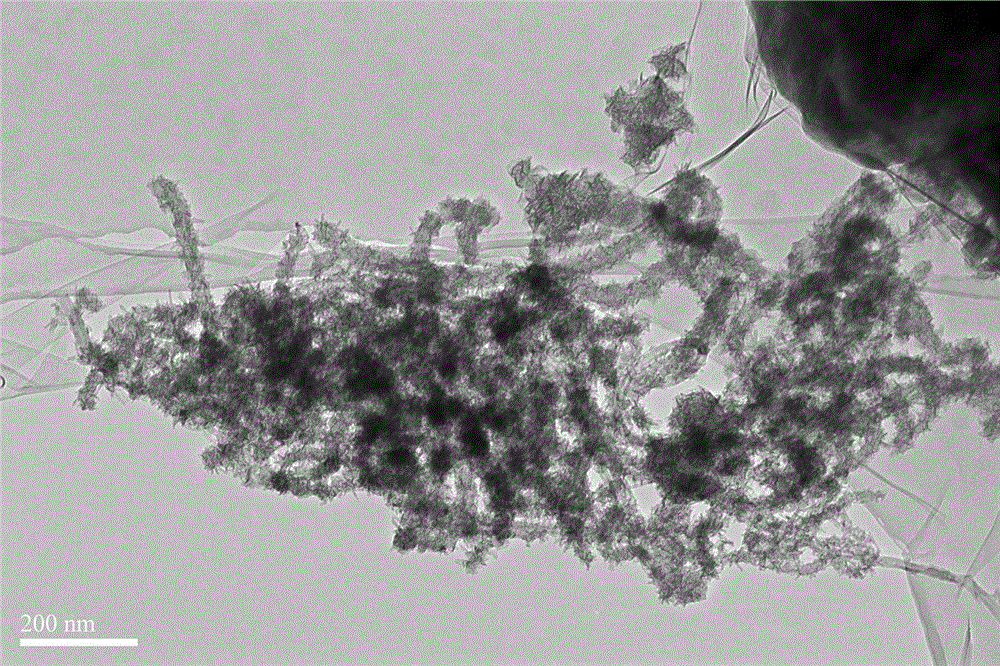

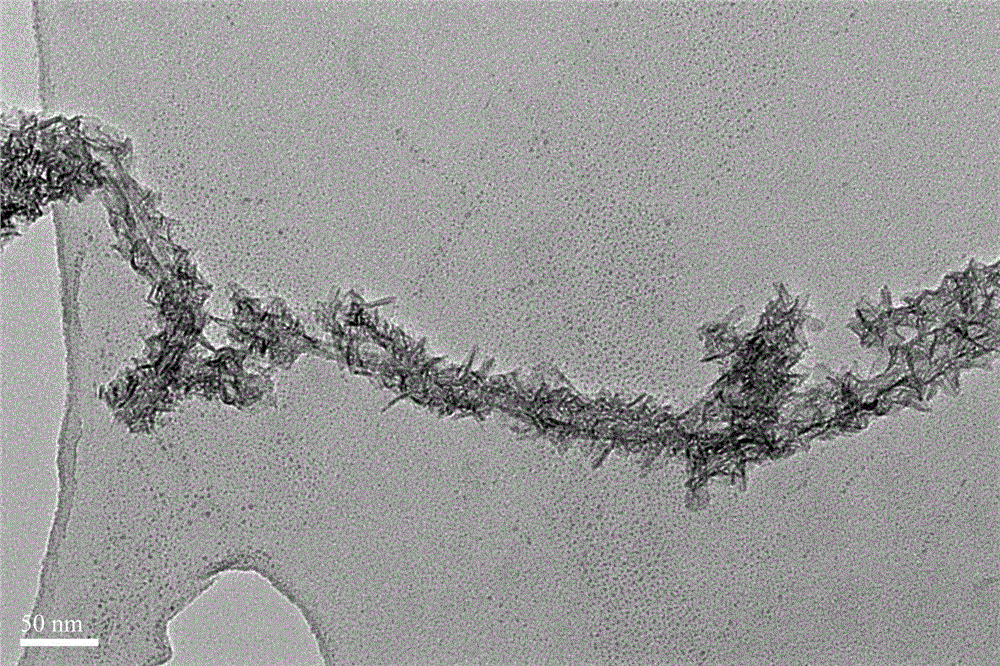

[0019] Disperse 0.3g of multi-walled carbon nanotubes in 50ml of deionized water, and sonicate for 20min; take 7g of potassium permanganate (KMnO 4 ) was dissolved in 150ml deionized water. The potassium permanganate solution was added dropwise to the multi-walled carbon nanotube dispersion and stirred continuously. After the dropwise addition, it was transferred to a polytetrafluoroethylene-lined hydrothermal crystallization kettle. The crystallization temperature was 160°C for 40 minutes. Vacuum filtration, washing with a large amount of water, and drying in an oven at 60°C, the multi-walled carbon nanotube-supported manganese oxide-based catalyst was prepared, which was designated as: MCNT-1.

Embodiment 3

[0021] Disperse 0.3g of multi-walled carbon nanotubes and 0.1g of polyvinylpyrrolidone in 50ml of deionized water, and sonicate for 20min; take 7g of potassium permanganate (KMnO4) and dissolve it in 150ml of deionized water. The potassium permanganate solution was added dropwise to the multi-walled carbon nanotube dispersion and stirred continuously. After the dropwise addition, it was transferred to a polytetrafluoroethylene-lined hydrothermal crystallization kettle. The crystallization temperature was 160°C for 40 minutes. Vacuum filtration, washing with a large amount of water, and drying in an oven at 60°C, the multi-walled carbon nanotube-supported manganese oxide-based catalyst was prepared, which was designated as: MCNT-140.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com