Method of treating high-concentration arsenic and cadmium in acidic waste water with granular titanium dioxide

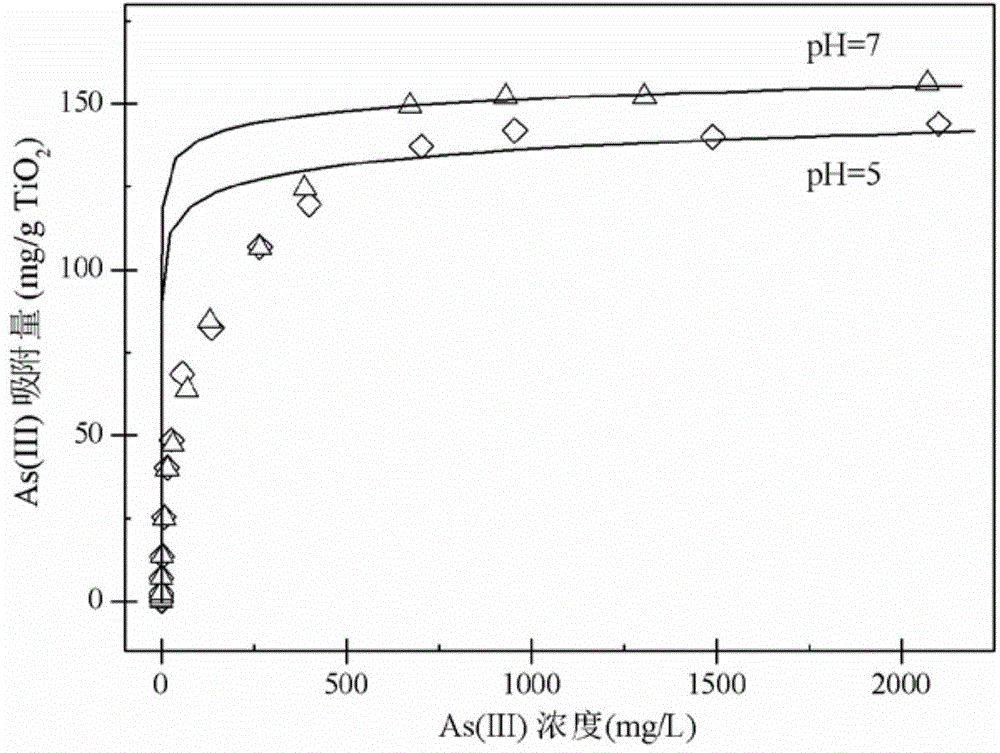

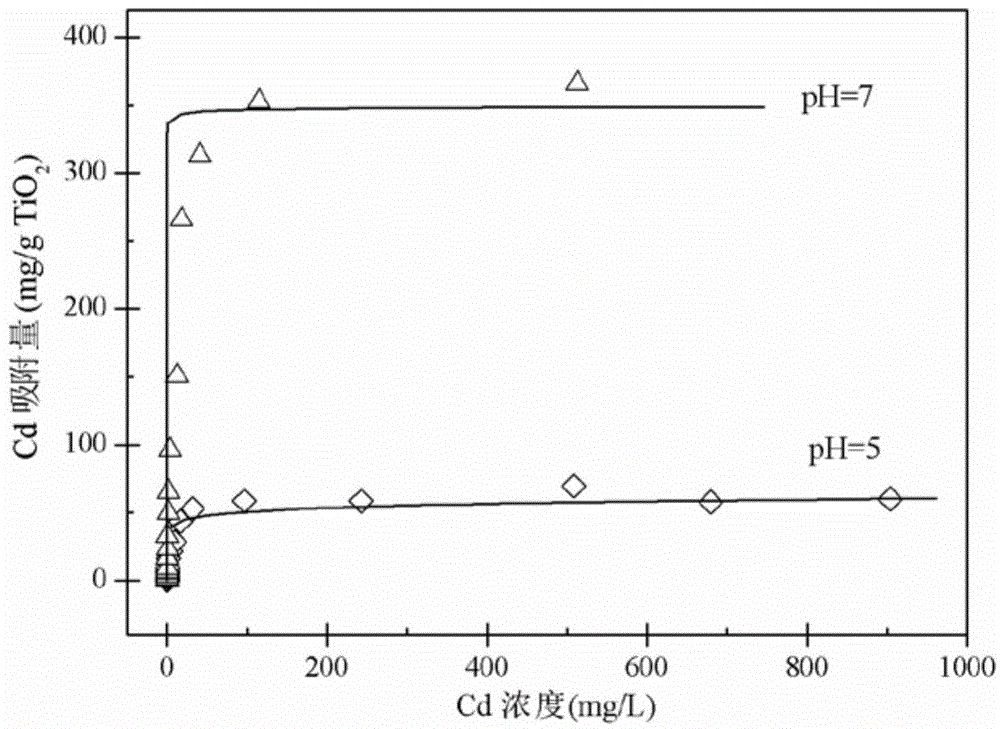

A technology of acidic wastewater and titanium dioxide, applied in the direction of chemical instruments and methods, separation methods, water/sewage multi-stage treatment, etc., can solve the problems of poor regeneration effect, easy migration of adsorbents, difficult recovery of powder adsorbents, etc., to solve the problem of discharge Not up to standard, stable treatment effect, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

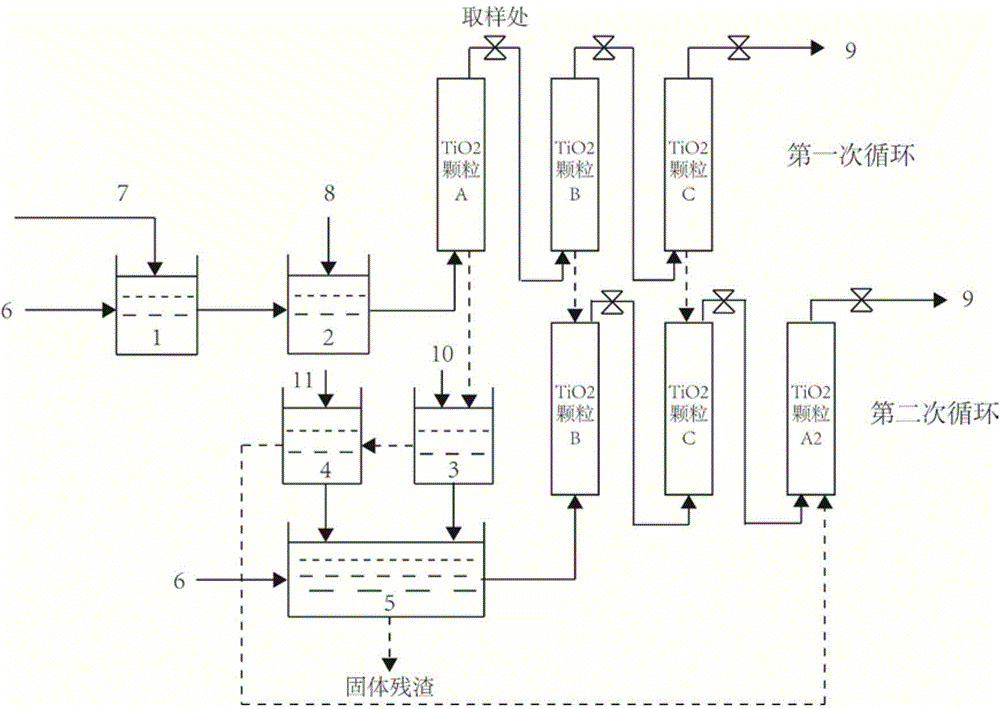

[0032]The removal of arsenic and cadmium in the acidic waste water of embodiment 1: with self-synthesized TiO 2 The particles are filled with three consecutive series of filter columns, and the acidic wastewater stock solution is adjusted to pH 7 by lime milk and industrial grade NaOH, and then pumped into the filter column for adsorption and removal. Samples were taken at the outlet of each column to ensure that the concentration of arsenic and cadmium in the outlet water reached the national sewage discharge standard. After the first column reached adsorption saturation, the TiO 2 For regeneration, the regenerated TiO 2 Refill the filter column and place it at the last column of the next cycle, so that it can be used repeatedly. The change curve of arsenic concentration in wastewater after treatment is shown in Figure 4 . The results show that after three consecutive adsorptions, the concentration of arsenic in the external drainage can be reduced to below 0.5mg / L, and ...

Embodiment 2

[0033] Example 2TiO 2 Adsorbent regeneration: the same treatment process as in Example 1, for the first column that reaches adsorption saturation, its TiO 2 Transfer to a 100mL polytetrafluoroethylene plastic bottle for backwash regeneration. First add 0.5mol / L sulfuric acid solution for backwashing, solid-liquid separation to obtain pickling solution and TiO 2 particles, followed by TiO 2 The particles were continuously backwashed three times with 5mol / L sodium hydroxide solution, and solid-liquid separation was carried out to obtain alkali washing solution and TiO 2 particles, and then TiO 2 The particles are washed with 0.5mol / L sulfuric acid solution and deionized water to neutrality, and solid-liquid separation is performed to obtain backwash liquid and regenerated TiO 2 particles. The volume of sulfuric acid and sodium hydroxide solution used was 70 mL. The regenerated TiO 2 Particle repacking filter cartridges are used to remove arsenic and cadmium from wastewate...

Embodiment 3

[0035] Example 3 Backwash liquid recovery: the same treatment process as in Example 1 and Example 2, after mixing the pickling solution and alkali washing solution obtained in Example 2, centrifuge to obtain supernatant and solid residue. The volume of the supernatant is about 40% of the volume of the treated water. The supernatant and the acidic wastewater stock solution are mixed at a volume ratio of 2:5 until neutral, and then re-enter the filter column for adsorption and removal. The XRD characterization results of the solid residue are shown in Figure 7 , the results show that its main components are sodium arsenite and sodium calcium arsenate, which can be used as chemical raw materials for arsenic and produce economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com