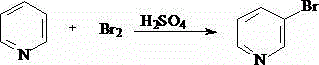

Synthetic method of 3-bromopyridine

A synthesis method, bromopyridine technology, applied in the field of synthesis of 3-bromopyridine, can solve the problems of expensive raw materials, high requirements for reaction conditions, and low yield, and achieve simple reaction steps, easy-to-obtain raw materials, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Drop 8.8g of bromine (50mmol) into 15ml (185mmol) and 95% sulfuric acid at 0°C, react at 130°C for 8 hours, cool down and pour into ice water after the reaction, adjust the pH to 8 with 6N sodium hydroxide, and 60ml of petroleum ether The extraction was divided into three times, and several layers were dried with anhydrous sodium sulfate after layering. After filtering the desiccant, the organic layer was concentrated, and then distilled with a Vigreux fractionating column. Gas phase analysis of the composition of the remaining substances, detection conditions: N 2 90ml / min, H 2 120ml / min, column temperature 165°C, injection 4ul, yield 75%.

Embodiment 2

[0020] Drop 8.8g of bromine (50mmol) into 15ml (185mmol) and 80% sulfuric acid at 0°C, react at 130°C for 8 hours, cool down and pour into ice water after the reaction, adjust the pH to 8 with 6N sodium hydroxide, and 60ml of petroleum ether The extraction was divided into three times, and several layers were dried with anhydrous sodium sulfate after layering. After filtering the desiccant, the organic layer was concentrated, and then distilled with a Vigreux fractionating column. Gas phase analysis of the composition of the remaining substances, detection conditions: N 2 90ml / min, H 2 120ml / min, column temperature 165°C, injection 4ul, yield 65%.

Embodiment 3

[0022] Drop 8.8g of bromine (50mmol) into 15ml (185mmol) and 90% sulfuric acid at 0°C, react at 130°C for 8 hours, cool down and pour into ice water after the reaction, adjust the pH to 8 with 6N sodium hydroxide, and 60ml of petroleum ether The extraction was divided into three times, and several layers were dried with anhydrous sodium sulfate after layering. After filtering the desiccant, the organic layer was concentrated, and then distilled with a Vigreux fractionating column. Gas phase analysis of the composition of the remaining substances, detection conditions: N 2 90ml / min, H 2 120ml / min, column temperature 165°C, injection 4ul, yield 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com