A Method for Optimizing the Homoepitaxial Growth of Single Crystal Diamond Using Plasma Baffles

A technology of single crystal diamond and plasma, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of polluting the cabin and the low quality of the lateral growth area, so as to ensure quality, reduce adhesion and deposition, The effect of increasing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

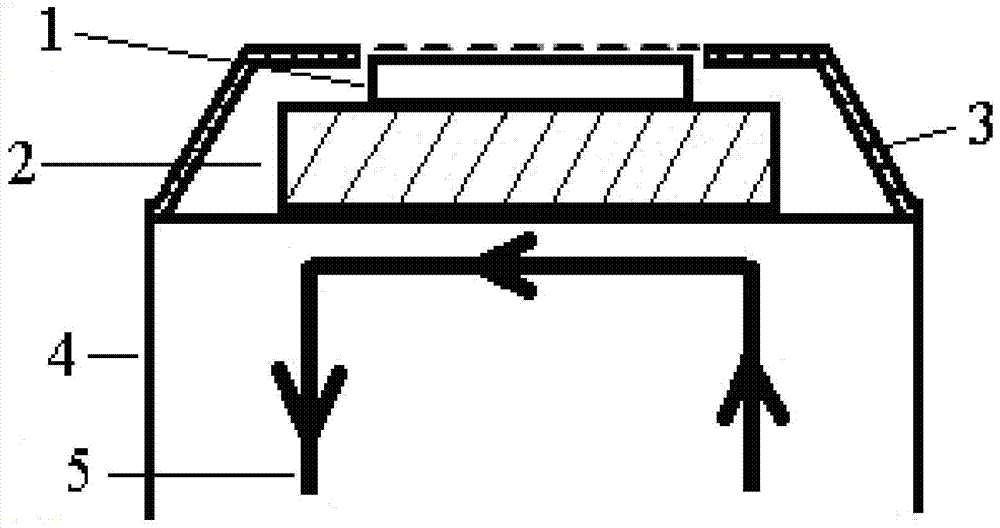

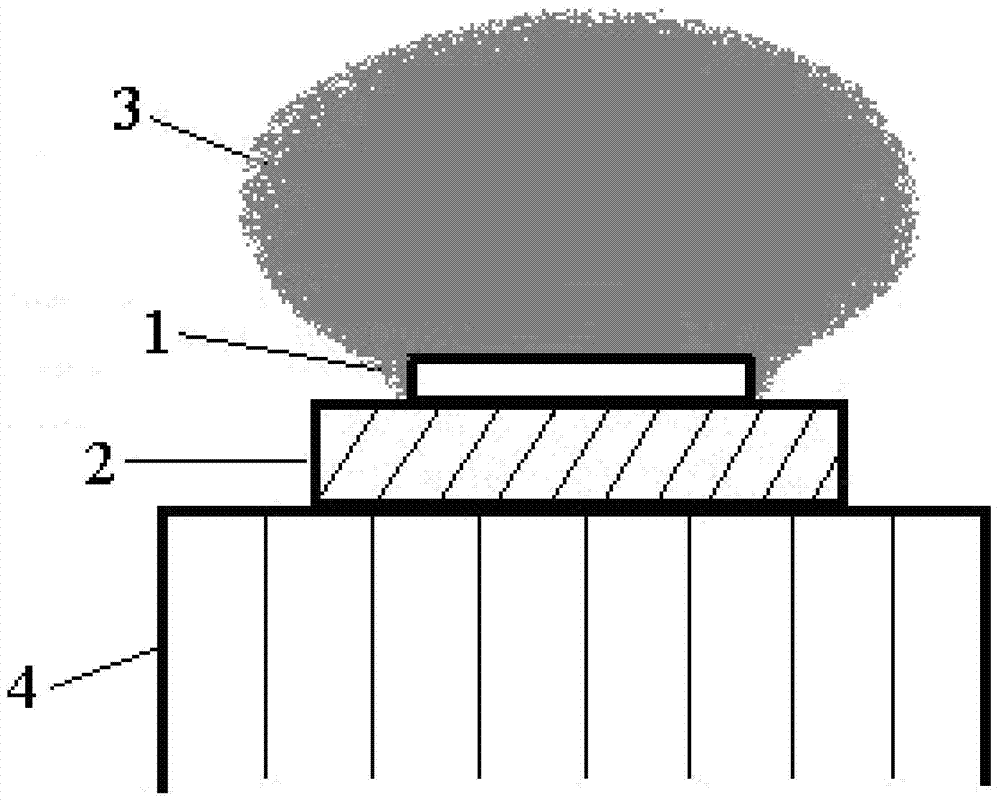

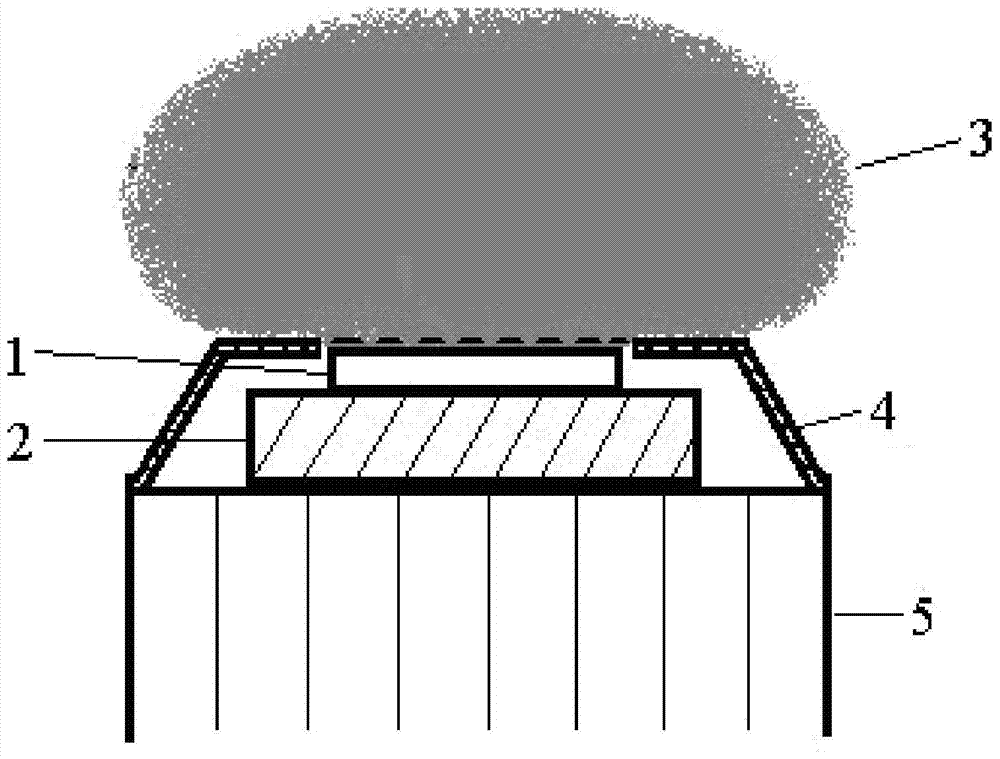

[0039] Specific implementation mode one: combine figure 1 , 9, 10, 11 and 12 specifically illustrate the present embodiment, a method for optimizing single crystal diamond homoepitaxial growth using a plasma baffle described in the present embodiment, specifically according to the following steps:

[0040] 1. Cleaning: cleaning the diamond seed crystal and the metal molybdenum substrate wafer to obtain the cleaned diamond seed crystal and the cleaned metal molybdenum substrate wafer;

[0041] 2. Welding: Weld the cleaned diamond seed crystal with gold foil on the cleaned metal molybdenum substrate disc to obtain a diamond seed crystal fixed on the metal molybdenum substrate disc;

[0042] 3. Place the sample:

[0043] Place the diamond seed crystal fixed on the metal molybdenum substrate wafer in the center of the base tray of the microwave plasma assisted chemical vapor deposition instrument;

[0044] 4. Place the plasma baffle:

[0045] The metal molybdenum plasma baffle...

specific Embodiment approach 2

[0058] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the diamond seed crystal is cleaned, specifically according to the following steps: under the condition that the ultrasonic power is 200W~600W, the diamond seed crystal Washing in acetone for 3 minutes to 5 minutes, in deionized water for 3 minutes to 5 minutes, and in absolute ethanol for 3 minutes to 5 minutes, to obtain diamond seed crystals after washing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0059] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the metal molybdenum substrate wafer is cleaned, specifically according to the following steps: Under certain conditions, the metal molybdenum substrate wafers are sequentially cleaned in acetone for 3 minutes to 5 minutes, in deionized water for 3 minutes to 5 minutes, and in absolute ethanol for 3 minutes to 5 minutes to obtain the cleaned metal molybdenum substrate disks. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com