Solar cell taking fluorinated graphene as high-resistance layer and preparing method thereof

A technology of solar cells and fluorinated graphene, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as light transmittance limitation, and achieve the effects of convenient operation, good light transmission rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

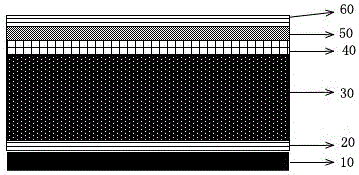

[0030] like figure 1 Shown, a kind of cadmium telluride thin film solar cell with fluorinated graphene thin film as high resistance layer, solar cell bottom layer is metal thin film layer 10, is provided with back contact layer 20 on metal thin film layer 10, on the back contact layer 20 is provided with an absorbing layer 30, the absorbing layer 30 material can be cadmium telluride, the window layer 40 is set on the absorbing layer 30, the material of the window layer 40 can be cadmium sulfide, and the window layer 40 is fluorinated graphene high The uppermost layer of the resistance layer 50 is a transparent conductive film layer 60 .

[0031] The thickness of the fluorinated graphene high resistance layer 50 is 0.34-20nm.

[0032] A method for preparing a cadmium telluride thin-film solar cell, using glass evaporated with a transparent oxide film layer (for example, indium tin oxide) as a substrate, and spin-coating the prepared fluorinated graphene on the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com