A non-annealing perovskite solar cell and its preparation method

A solar cell and perovskite type technology, applied in the field of solar cells, can solve the problems of reducing the crystallization activation energy of perovskite thin films, complicated process and high cost, and achieve the effects of convenient industrial production, easy repetition and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

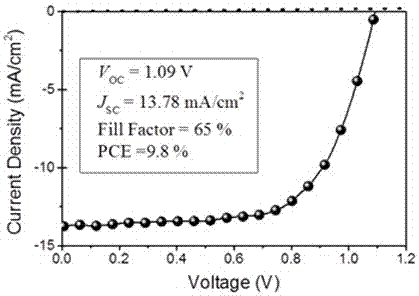

Embodiment 1

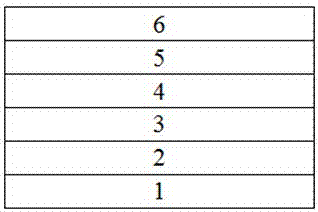

[0025] (1) Provide an ITO glass substrate and perform standardized cleaning;

[0026] (2) Methylammonium iodide (MAI) and lead chloride (PbCl 2 ) and indium chloride (InCl 3 ) was dissolved in the DMF solution at a molar ratio of 3:1:0.3, and stirred for 5 hours to obtain a 30wt% perovskite DMF solution;

[0027] (3) Spin-coat the PEDOT:PSS solution on the transparent electrode of the substrate, accelerate to 4500rpm and rotate for 40 seconds to form a uniform anode modification layer, and anneal at 100°C for 20 minutes;

[0028] (4) Process the perovskite layer film on the PEDOT:PSS film by spin coating method, accelerate to 4000rpm and rotate for 40 seconds, and disorderly annealing treatment can obtain a photosensitive layer with uniform crystallinity;

[0029] (5) The electron transport layer PCBM is processed by spin coating on the perovskite film, accelerated to 2000rpm and rotated for 40 seconds to obtain a uniform electron transport layer film;

[0030] (6) The cath...

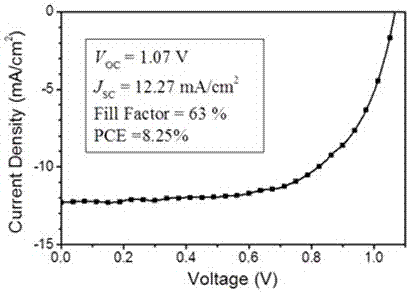

Embodiment 2

[0032] (1) Provide an ITO flexible substrate and perform standardized cleaning;

[0033] (2) Methylammonium iodide (MAI) and lead chloride (PbCl 2 ) and indium chloride (InCl 3 ) was dissolved in the DMF solution at a molar ratio of 3:1:0.3, and stirred for 5 hours to obtain a 30wt% perovskite DMF solution;

[0034] (3) Spin-coat the PEDOT:PSS solution on the transparent electrode of the substrate, accelerate to 4500rpm and rotate for 40 seconds to form a uniform anode modification layer, and anneal at 100°C for 20 minutes;

[0035] (4) Process the perovskite layer film on the PEDOT:PSS film by spin coating method, accelerate to 4000rpm and rotate for 40 seconds, and disorderly annealing treatment can obtain a photosensitive layer with uniform crystallinity;

[0036] (5) The electron transport layer PCBM is processed by spin coating on the perovskite film, accelerated to 2000rpm and rotated for 40 seconds to obtain a uniform electron transport layer film;

[0037] (6) The c...

Embodiment 3

[0039] (1) Provide an ITO flexible substrate and perform standardized cleaning;

[0040] (2) Methylammonium iodide (MAI) and lead chloride (PbCl 2 ) and indium chloride (InCl 3 ) was dissolved in the DMF solution at a molar ratio of 3:1:0.25, and stirred for 2 hours to obtain a 30wt% perovskite DMF solution;

[0041] (3) Spin-coat the PEDOT:PSS solution on the transparent electrode of the substrate, accelerate to 4500rpm and rotate for 40 seconds to form a uniform anode modification layer, and anneal at 95°C for 40 minutes;

[0042] (4) Process the perovskite layer film on the PEDOT:PSS film by spin coating method, accelerate to 4000rpm and rotate for 40 seconds, and disorderly annealing treatment can obtain a photosensitive layer with uniform crystallinity;

[0043] (5) The electron transport layer PCBM is processed by spin coating on the perovskite film, accelerated to 2000rpm and rotated for 40 seconds to obtain a uniform electron transport layer film;

[0044] (6) The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com