Granular oil shale pelletizing process and device

A technology of kerogen shale and small particles, which is applied in the field of waste gas kerogen shale reuse, which can solve the problems of high energy consumption, continuous production of difficult industrial equipment, long time of ball rolling process, etc., and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

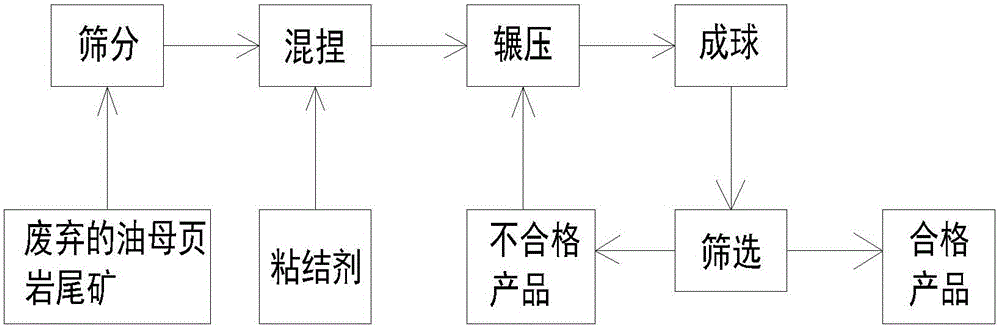

[0055] This embodiment provides a small particle kerogen shale pelletizing process, which includes the following steps:

[0056] A. Screening: The discarded oil shale tailings are screened to obtain small grains of oil shale with a particle size less than or equal to 3mm;

[0057] B. Kneading: mixing and kneading the small particle kerogen obtained in step A and the binder, so that the small particle kerogen is initially pulverized and fully mixed with the binder;

[0058] C. Rolling: crushing and rolling the small particle kerogen shale and binder that have been preliminarily crushed and fully mixed in step B, so as to obtain plastic kerogen shale;

[0059] D. Balling: processing the plastic kerogen shale obtained in step C into a spherical shape to obtain spherical kerogen shale;

[0060] E. Screening: Screen the spherical kerogen shale obtained in step E, and the spherical kerogen shale with a particle size greater than or equal to 40mm is a qualified product, and the sphe...

Embodiment 2

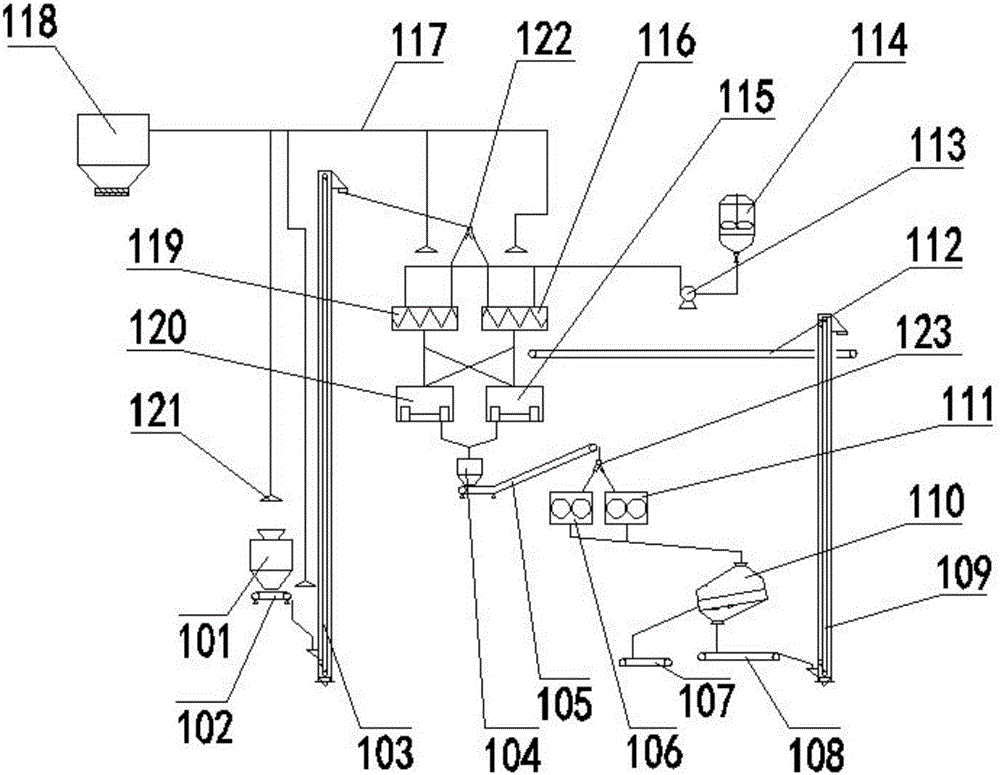

[0065] Such as figure 2 As shown, this embodiment provides a small particle kerogen shale pelletizing device, which is used in the above small particle kerogen shale pelletizing process, including: a raw material warehouse 101, a first weighing belt conveyor 102, and a first bucket elevator 103 , kneading machine, wheel rolling machine, the second weighing belt conveyor 105, pressure ball forming machine, circular vibrating screen 110, the first belt conveyor 108, the second belt conveyor 112, the second bucket elevator 109, sticky The binder mixing tank 114 and the binder metering pump 113; the binder mixing tank 114 is connected to the kneader through the binder metering pump 113; the raw material bin 101 is provided with a vibrating screen, and the circular vibrating screen 110 is provided with a finished product outlet And return ore outlet.

[0066] The first weighing belt conveyor 102 is located below the discharge port of the raw material bin 101, the feed port of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com