Preparation method for efficient oil absorption carbon aerogel material

A carbon aerogel, aerogel technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., can solve the problems of uneven dispersion of carbon nanotubes, complicated synthesis process, high toxicity of reagents, etc., and achieve good adsorption. properties and mechanical strength, a wide range of raw material sources, the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

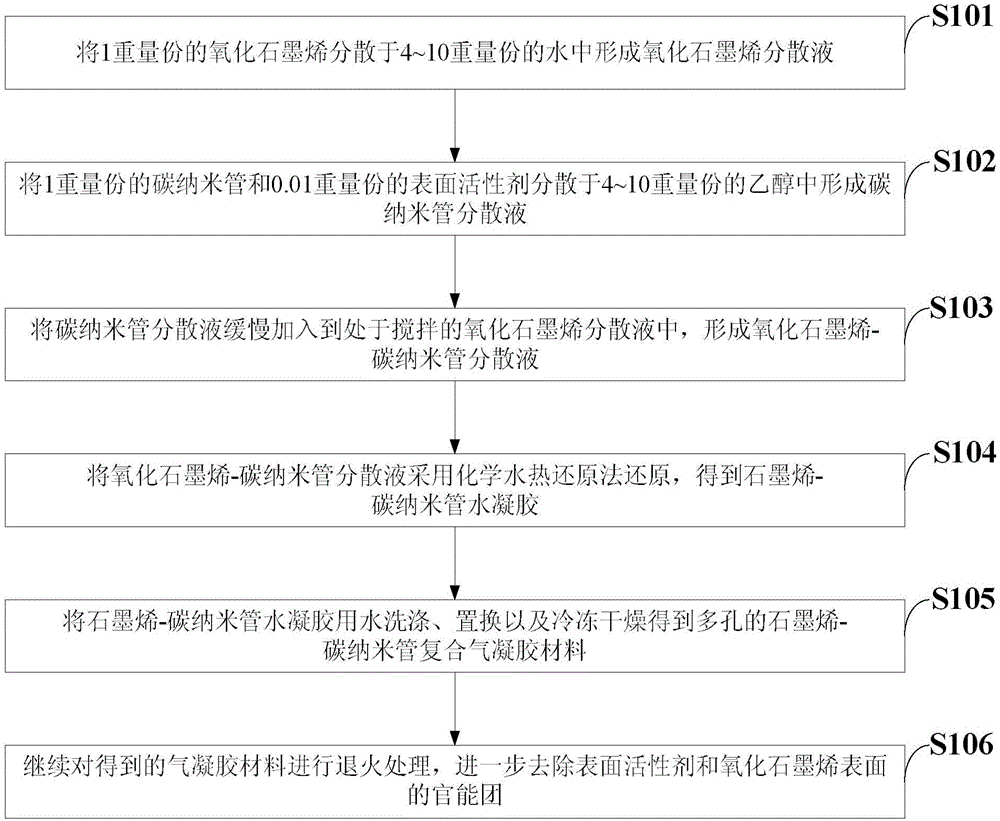

[0044] Step (a): 1 weight part of graphene oxide is dispersed in 10 weight parts of water, stirred for 3 hours to form a graphene oxide dispersion;

[0045] Step (b): dispersing 1 weight part of carbon nanotubes and 0.01 weight part of polyvinylpyrrolidone in 10 weight parts of ethanol, ultrasonicating for 5 hours to form a carbon nanotube dispersion;

[0046] Step (c): slowly adding the carbon nanotube dispersion to the stirred graphene oxide dispersion, and continuing to stir for 1 hour to form a graphene oxide-carbon nanotube dispersion;

[0047] Step (d): Take 10 ml of the dispersion in step (c), add 200 μl of ethylenediamine, stir for 10 minutes, put it into a reaction kettle at 120 ° C, and react for 12 hours to obtain a graphene-carbon nanotube hydrogel;

[0048] Step (e): wash the hydrogel in step (d) with ultrapure water for 10 times, freeze and shape at -70°C, and freeze-dry to obtain the carbon airgel material.

Embodiment 2

[0050] Step (a): 1 weight part of graphene oxide is dispersed in 4 weight parts of water, stirred for 3 hours to form a graphene oxide dispersion;

[0051] Step (b): dispersing 1 weight part of carbon nanotubes and 0.01 weight part of polyvinylpyrrolidone in 4 weight parts of ethanol, and ultrasonicating for 5 hours to form a carbon nanotube dispersion;

[0052] Step (c): slowly adding the carbon nanotube dispersion to the stirred graphene oxide dispersion, and continuing to stir for 1 hour to form a graphene oxide-carbon nanotube dispersion;

[0053] Step (d): Take 10 ml of the dispersion in step (c), add 200 μl of ethylenediamine, stir for 10 minutes, put it into a reaction kettle at 120 ° C, and react for 12 hours to obtain a graphene-carbon nanotube hydrogel;

[0054] Step (e): washing the hydrogel in step (d) with ultrapure water for 10 times, freezing and forming at -70°C, and freeze-drying to obtain a carbon airgel material;

[0055] Step (f): annealing the graphene-ca...

Embodiment 3

[0057] Step (a): dispersing 1 weight part of graphene oxide in 5 weight parts of water, stirring for 3 hours to form a graphene oxide dispersion;

[0058] Step (b): dispersing 1 weight part of carbon nanotubes and 0.01 weight part of polyvinylpyrrolidone in 10 weight parts of ethanol, ultrasonicating for 5 hours to form a carbon nanotube dispersion;

[0059] Step (c): slowly adding the carbon nanotube dispersion to the stirred graphene oxide dispersion, and continuing to stir for 1 hour to form a graphene oxide-carbon nanotube dispersion;

[0060] Step (d): Take 10 ml of the dispersion in step (c), add 200 μl of ammonia water, stir for 10 minutes, put it in a reaction kettle at 90 ° C, and react for 24 hours to obtain a graphene-carbon nanotube hydrogel;

[0061] Step (e): washing the hydrogel in step (d) with ultrapure water for 10 times, freeze-forming at -70° C., and freeze-drying to obtain a carbon gel material.

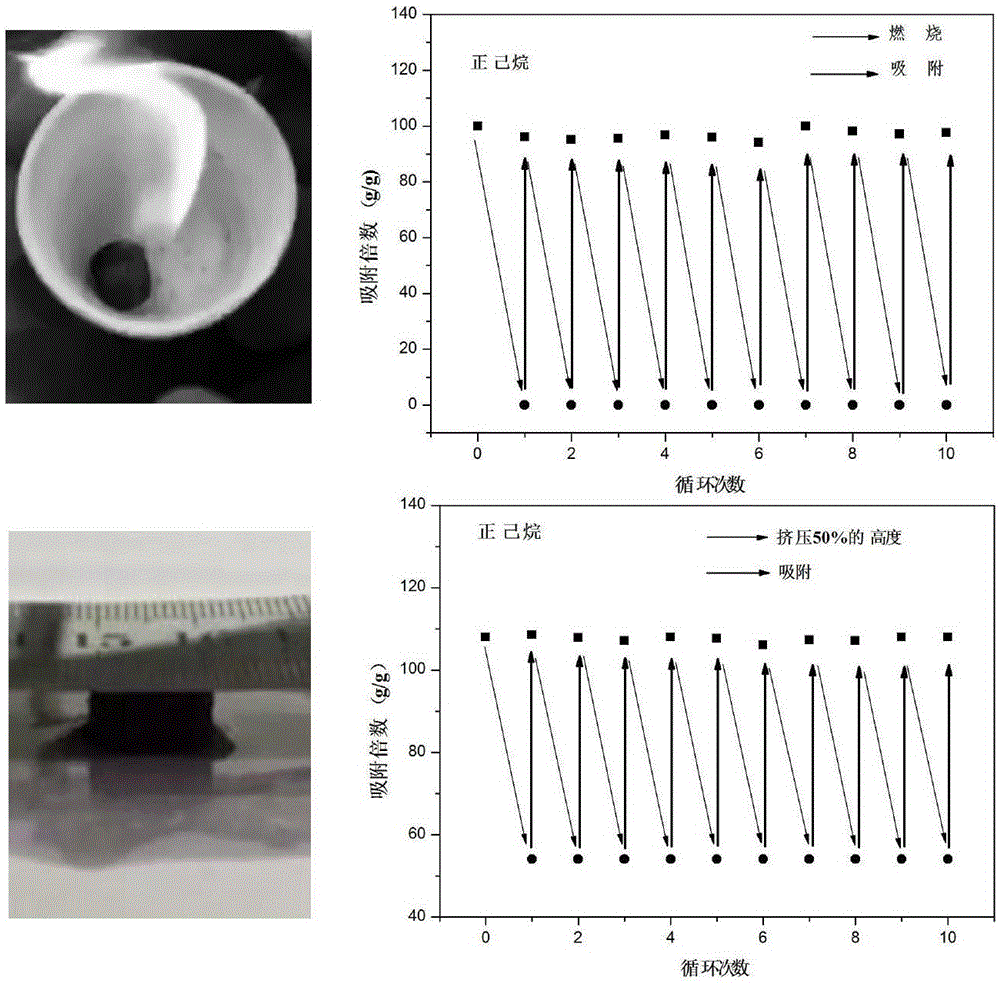

[0062] figure 2 It is the SEM electron micrograph of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com