Preparation method for nano-hydroxyapatite

A nano-hydroxyapatite and calcium-phosphorus technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of long reaction time, low production efficiency, slow mass transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

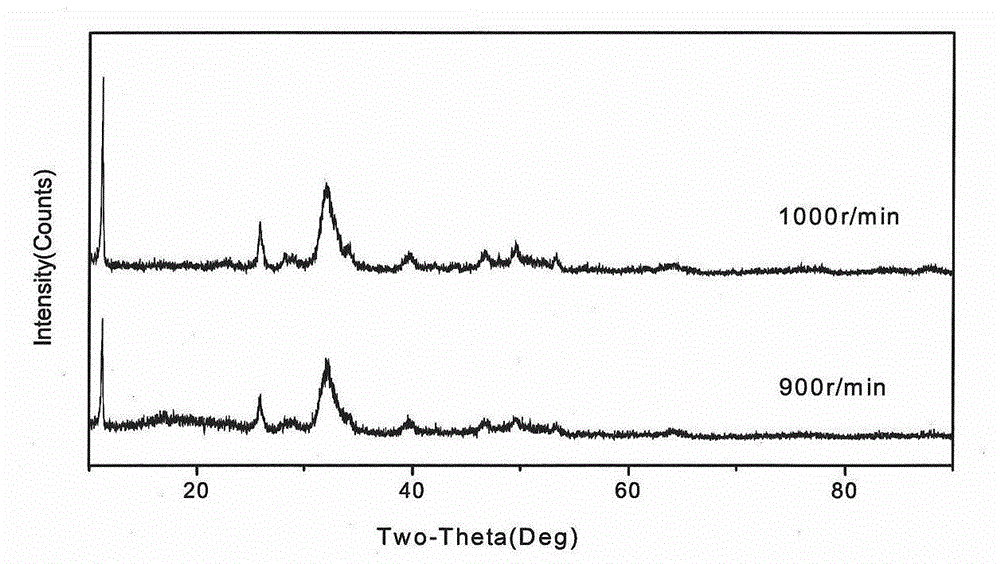

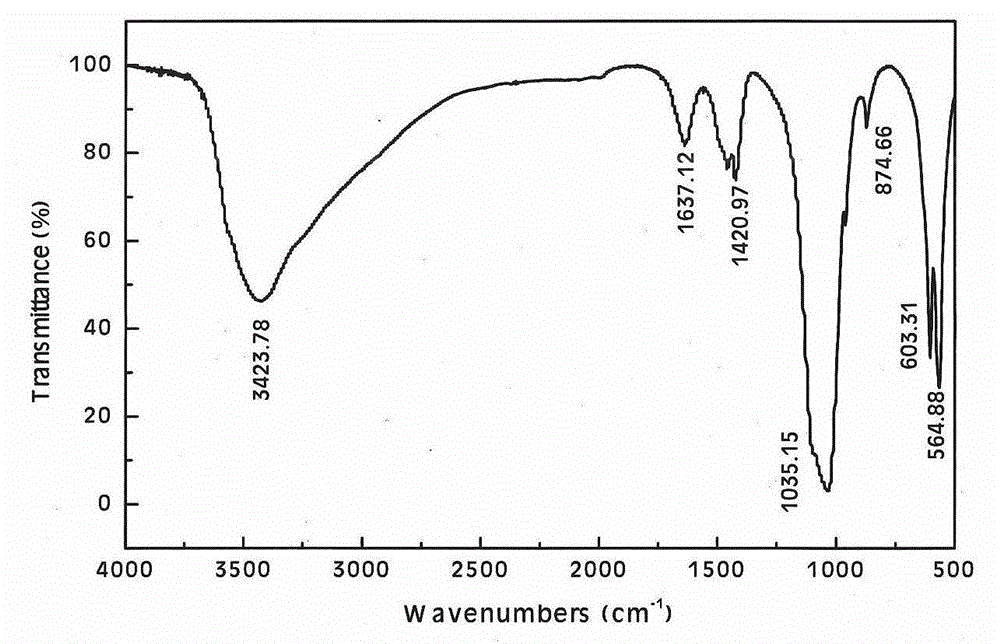

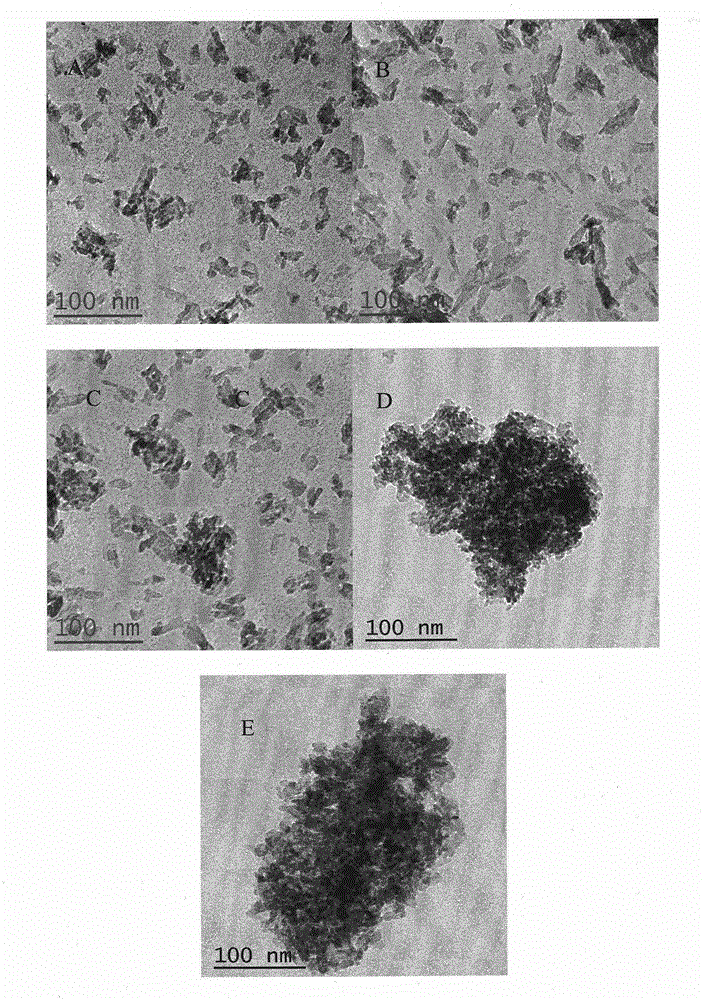

Embodiment 1

[0018] Prepare 0.25mol / LCa(NO 3 ) 2 4H 2 O, Na 3 PO 4 12H 2 O each 5L raw material, add 80g acetamide to Na 3 PO 4 In the solution, the reaction was carried out in a rotating packed bed at a flow rate of 40L / h and a temperature of 40°C. The rotating speed of the rotating packed bed was 900r / min, and the reaction was carried out by using the supergravity method; the precipitate after the reaction was aged at room temperature After drying for 36 hours, centrifuging, washing and drying, the drying temperature was 100° C., and after drying for 5 hours, nano-hydroxyapatite was obtained, and the yield per pass was 89.3%.

Embodiment 2

[0020] Prepare 0.25mol / LCa(NO 3 ) 2 4H 2 O, Na 3 PO 4 12H 2 O each 5L raw material, add 80g acetamide to Na 3 PO 4 In the solution, the reaction was carried out in a rotating packed bed with a flow rate of 40L / h and a temperature of 60°C. The rotating speed of the rotating packed bed was 1000r / min, and the reaction was carried out by using the supergravity method; the precipitate after the reaction was aged at room temperature After drying for 36 hours, centrifuging, washing and drying, the drying temperature is 100° C., and after drying for 5 hours, nano-hydroxyapatite is obtained, and the single-pass yield is 90.6%.

Embodiment 3

[0022] Prepare 0.25mol / LCa(NO 3 ) 2 4H 2 O, Na 3 PO 4 12H 2 O each 5L raw material, add 80g acetamide to Na 3 PO 4 In the solution, the reaction was carried out in a rotating packed bed at a flow rate of 40L / h and a temperature of 80°C. The rotating speed of the rotating packed bed was 1500r / min, and the reaction was carried out by using the supergravity method; the precipitate after the reaction was aged at room temperature After drying for 36 hours, centrifuging, washing and drying, the drying temperature is 100° C., and after drying for 5 hours, nano-hydroxyapatite is obtained, and the single-pass yield is 66.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com