Manufacturing method of ceramic bracket for magnetic suspension variable frequency centrifuge coil

The technology of a ceramic bracket and a manufacturing method is applied in the field of magnetic levitation variable frequency centrifuges, which can solve the problems of insecurity, reduced motor service life, poor anti-aging performance of coil brackets, etc., and achieves high insulation resistance and strength, and prevents aging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

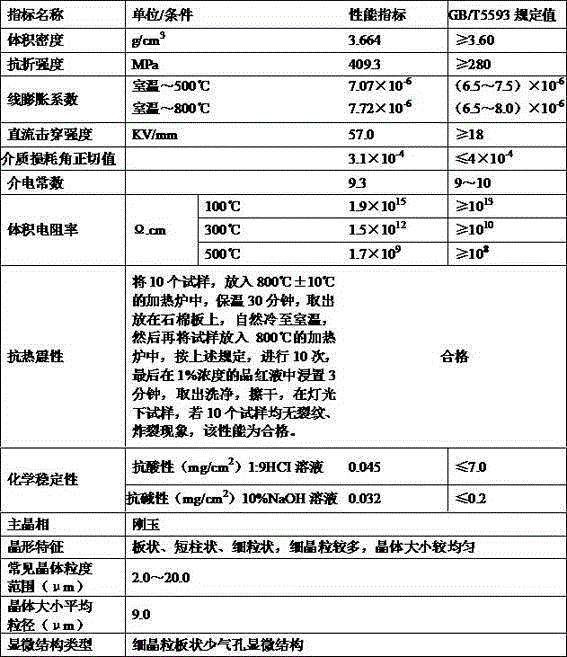

Image

Examples

Embodiment 1

[0030] Al2O3 90.00-95.00%, Calcium Oxide 1.00-3.00%, Niobium Pentoxide 1.00-3.00%, Barium Carbonate 2.00-4.00%, Suzhou Soil 1.00-3.00% weigh Al2O3, Calcium oxide, niobium pentoxide, calcium carbonate and Suzhou soil powder, stir evenly, and dry in a drying oven until the water content is lower than or equal to 0.03%, put the mixed powder into the ball mill Carry out ball milling. During the ball milling, the weight ratio of the powder to the ball is 1:2, and the ball milling is continued for 17-21 hours; after the ball milling, the measured particle size of the mixed powder is 2.0-4.0 μm. Among them, the ball mill used in the ball mill is a drum-type ball mill lined with alumina lining bricks. The particle size of the powder is measured by the Xiangke SK-5 particle size analyzer, and the weight of the mixed powder after ball milling is 8~ 13% white wax and 0.2-0.6% yellow wax by weight of the mixed powder, that is, the weight of the added white wax is 8-13% of the weight of th...

Embodiment 2

[0032] This embodiment provides a ceramic support for magnetic levitation frequency conversion centrifuge coils, the ceramic support is made of ceramic materials with the following components: 93.5% aluminum oxide, 1.5% calcium oxide, 1.5% niobium pentoxide, 2 % barium carbonate and 1.5% Suzhou soil.

Embodiment 3

[0034] This embodiment provides a ceramic support for magnetic levitation frequency conversion centrifuge coils, the ceramic support is made of ceramic materials with the following components: 94.5% aluminum oxide, 1.5% calcium oxide, 1% niobium pentoxide, 2 % barium carbonate and 1% Suzhou soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com