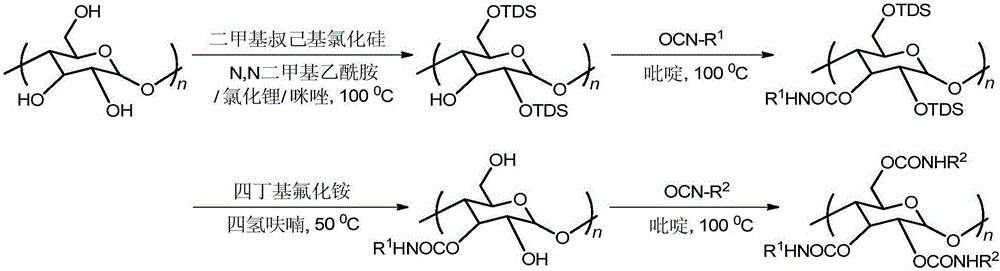

Regioselective synthesis and application methods for amylose derivatives with different carbamate side groups

A carbamate, regioselective technology, applied in chemical instruments and methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] 1. Take 1g of amylose and vacuum-dry at 105°C for 4h, raise the temperature to 120°C, then stir and reflux in anhydrous N,N-dimethylacetamide for 4h; add 1.5g of lithium chloride after cooling to 100°C; Continue to stir for 2 hours, add 2.02 g of imidazole after cooling to room temperature; add excess dimethyl tert-hexyl silicon chloride after reflux for 20 minutes, reheat to 100 ° C, continue stirring and reflux for 24 hours to stop the reaction; cool to room temperature, add buffer ( Add 3.54 g of potassium dihydrogen phosphate and 7.14 g of dipotassium hydrogen phosphate to 1000 ml of distilled water), settle and filter, wash with ethanol and water (volume ratio 9:1), and vacuum-dry at 60° C. to constant weight. The yield is 80%.

[0029] 2. Vacuum-dry the above intermediate product at 80°C for 3h, then reflux in anhydrous pyridine for 6h, add excess 3,5-dichlorophenyl isocyanate after heating up to 100°C, continue to reflux at 100°C for 12h, then stop The reaction w...

specific Embodiment approach 2

[0034] 1. Take 1g of amylose and vacuum-dry at 105°C for 4h, raise the temperature to 120°C, then stir and reflux in anhydrous N,N-dimethylacetamide for 4h; add 1.5g of lithium chloride after cooling to 100°C; Continue to stir for 2 hours, add 2.02 g of imidazole after cooling to room temperature; add excess dimethyl tert-hexyl silicon chloride after reflux for 20 minutes, reheat to 100 ° C, continue stirring and reflux for 24 hours to stop the reaction; cool to room temperature, add buffer ( Add 3.54 g of potassium dihydrogen phosphate and 7.14 g of dipotassium hydrogen phosphate to 1000 ml of distilled water), settle and filter, wash with ethanol and water (volume ratio 9:1), and vacuum-dry at 60° C. to constant weight. The yield is 80%.

[0035] 2. Vacuum-dry the above intermediate product at 80°C for 4h, then reflux in anhydrous pyridine for 6h, heat up to 100°C, add excess 4-chlorophenyl isocyanate, continue to reflux at 100°C for 14h, then stop the reaction, use Wash tho...

specific Embodiment approach 3

[0040] 1. Take 1g of amylose and vacuum-dry at 105°C for 4h, raise the temperature to 120°C, then stir and reflux in anhydrous N,N-dimethylacetamide for 4h; add 1.5g of lithium chloride after cooling to 100°C; Continue to stir for 2 hours, add 2.02 g of imidazole after cooling to room temperature; add excess dimethyl tert-hexyl silicon chloride after reflux for 20 minutes, reheat to 100 ° C, continue stirring and reflux for 24 hours to stop the reaction; cool to room temperature, add buffer ( Add 3.54 g of potassium dihydrogen phosphate and 7.14 g of dipotassium hydrogen phosphate to 1000 ml of distilled water), settle and filter, wash with ethanol and water (volume ratio 9:1), and vacuum-dry at 60° C. to constant weight. The yield is 80%.

[0041] 2. Vacuum-dry the above intermediate product at 80°C for 4h, then reflux in anhydrous pyridine for 6h, add excess phenyl isocyanate after heating up to 100°C, stop the reaction after continuing to reflux at 100°C for 14h, and wash th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com