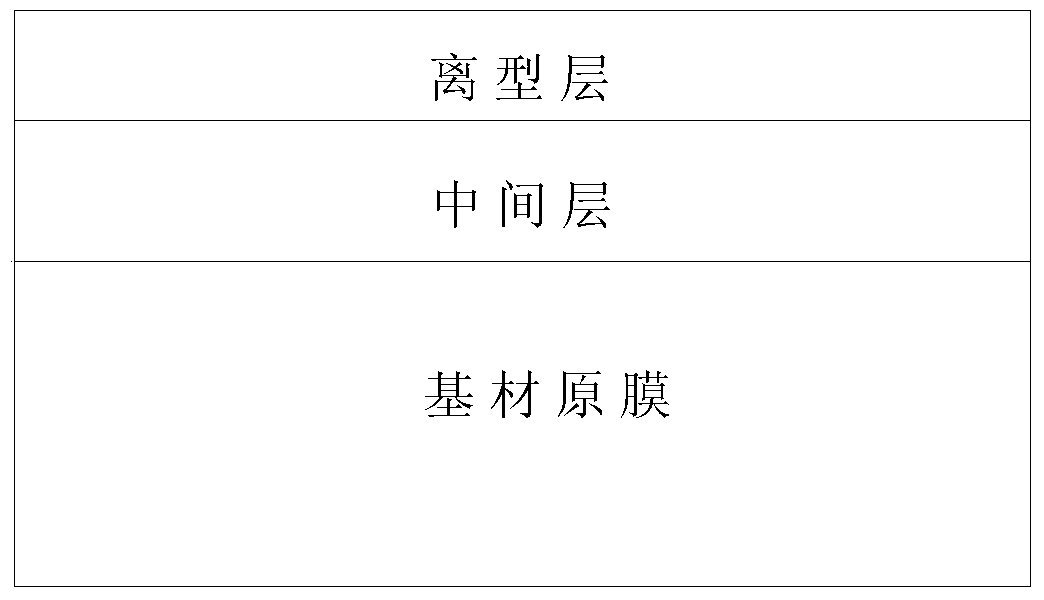

Release film and preparation method thereof

A technology of release film and release layer, which is applied in coating and other directions, can solve the problems of increasing interference fringes and increasing costs, and achieve the effects of reducing cost, improving adhesion and durability, and good optical appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the method for preparing the release film provided by the present invention, the processing of the intermediate layer and the release layer can be produced by a wet coating process. No special definition is made for painting methods. What is necessary is just to satisfy the film thickness specified by this invention.

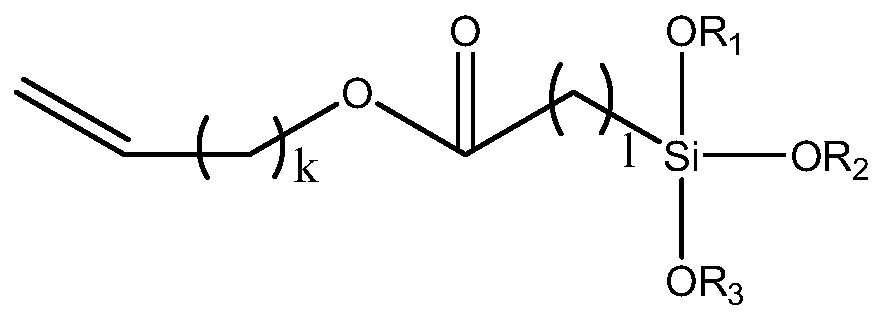

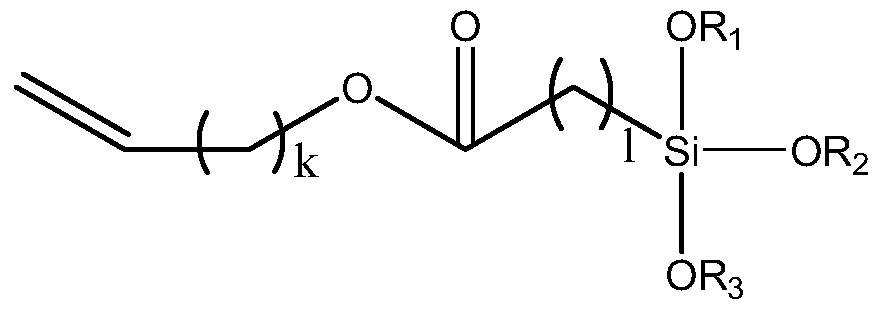

[0048] In a preferred embodiment, the step of coating the material for the intermediate layer includes: mixing epoxy silane, unsaturated functional group silane and metal chelate in a proportion, and dissolving with an organic solvent, heating and stirring, to obtain the intermediate Layer coating materials.

[0049] In a preferred embodiment, the step of forming the intermediate layer includes: placing the intermediate layer coating material on one surface of the original film of the base material for knife coating, and drying at 80-120°C for 0.5-5 After minutes, the middle layer is obtained.

[0050] In a preferred embodiment, the step of forming a relea...

Embodiment 1

[0054] The intermediate layer material 3-(methacryloxy)propyltrimethoxysilane, 3-(2,3-glycidoxy)propyltrimethoxysilane and metal aluminum chelate BY24-846E are 40wt: 40%wt: 20%wt ratio is mixed, and diluted with organic solvent methyl ethyl ketone and ethyl acetate, dissolved, heated and stirred to obtain the intermediate layer coating material. On one surface of the PET substrate, the above-mentioned interlayer coating material was knife-coated using a wire bar, and dried at 100°C for 1 minute to obtain an interlayer film with a film thickness of 100 nanometers.

[0055] On the intermediate layer, the mixture of silicon-based release coating LTC750A and catalyst NC-25 was knife-coated with a wire rod and dried at 100°C for 1 minute to obtain a release film with a film thickness of 120 nanometers.

[0056] Experimental evaluation and results: The interference fringe test is under three-wavelength light, and the reflected light is used to visually evaluate the interference fringe. T...

Embodiment 2

[0059] The intermediate layer material 3-(methacryloxy)propyltrimethoxysilane, 3-(2,3-glycidoxy)propyltrimethoxysilane and metal aluminum chelate BY24-846E are 20% The mixture is mixed in a ratio of wt: 60% wt: 20% wt, diluted with organic solvent methyl ethyl ketone and ethyl acetate, dissolved, and heated and stirred to obtain an intermediate layer coating material. On one surface of the PET substrate, the above-mentioned interlayer coating material was knife-coated using a wire bar, and dried at 100°C for 1 minute to obtain an interlayer film with a film thickness of 25 nm.

[0060] On the intermediate layer, the mixture of silicon-based release coating LTC750A and catalyst NC-25 was knife-coated with a wire rod and dried at 100°C for 1 minute to obtain a release film with a thickness of 15 nm.

[0061] Experimental evaluation and results: The interference fringe test is under three-wavelength light, and the reflected light is used to visually evaluate the interference fringe. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com