Biodegradable quasi-dry cutting oil and preparation method thereof

A quasi-dry cutting and biodegradable technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as lubrication and cooling problems that cannot be solved well, affect the health of operators, processing sites and environmental pollution, etc. Achieving significant environmental protection effects, excellent biodegradability, and good extreme pressure and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: 76.06kg (1000mol) of acrylic acid and 58.04kg (500mol) of maleic acid, 44.48kg (600mol) of n-butanol, 61.3kg (600mol) of hexanol, and 214.8kg (800mol) of oleyl alcohol are added to the polymerization In the kettle, add 30kg of dilute sulfuric acid (5%) as a catalyst, fill in nitrogen to convert the air in the reactor to react, the reaction temperature is 200°C, and the reaction time is 4 hours. .

[0040] Step 2: Add 1.1kg of dibenzoyl peroxide to the polymerization kettle and stir, keep the reaction temperature at 170°C, after 4 hours of polymerization, discharge the polymer in the polymerization kettle, filter and remove other impurities at a temperature above 100°C, It is acrylic maleic acid polyester.

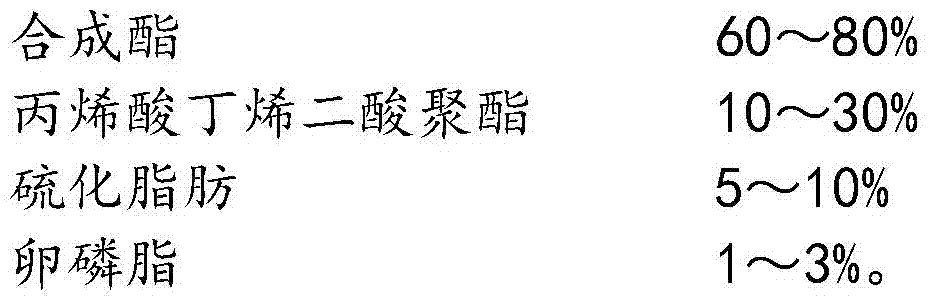

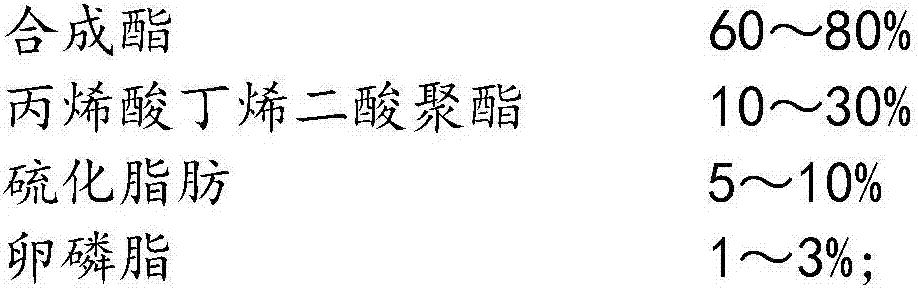

[0041] Take 20kg of acrylic maleic acid polyester, 20kg of trimethylolpropane trioleate, 20kg of butyl oleate, 28kg of dioctyl suberate, 10kg of vulcanized lard, and 2kg of lecithin in the above steps at about 50°C temperature to transparent to prepare a bi...

Embodiment 2

[0056]Step one: 76.06kg (1000mol) acrylic acid and 116.07kg (1000mol) fumaric acid, 2-amyl alcohol of 88.16kg (1000mol), 186.38kg (1000mol) of lauryl alcohol are added in the polymerization kettle, add 23kg dilute sulfuric acid (10 %) as a catalyst, filled with nitrogen to convert the air in the reactor to react, the reaction temperature is 180°C, the reaction time is 5 hours, after the reaction, the water is decompressed and discharged, which is acrylic acid fumarate.

[0057] Step 2: Add 0.96kg of lauroyl peroxide into the polymerization kettle and stir, keep the reaction temperature at 180°C, after 3 hours of polymerization, discharge the polymer in the polymerization kettle, filter and remove other impurities at a temperature above 100°C, that is Acrylic fumarate polyester.

[0058] Take 30kg of acrylic fumaric acid polyester, 10kg of pentaerythritol tetraoleate, 50kg of ethyl oleate, 9kg of vulcanized cottonseed oil, and 1kg of lecithin in the above steps and stir until t...

Embodiment 3

[0060] Step 1: Add 76.06kg (1000mol) of acrylic acid, 98.02kg (1000mol) of maleic anhydride, 130.25kg (1000mol) of isooctyl alcohol, 158.3kg (1000mol) of isodecyl alcohol, and 76.1kg (1000mol) of n-hexanol to the polymerization kettle Inside, add 43kg dilute sulfuric acid (5%) as catalyzer, fill in nitrogen and convert the air in the reactor to react, the reaction temperature is 220 DEG C, the reaction time is 3 hours, after the reaction, depressurize and discharge moisture, which is acrylic acid maleate.

[0061] Step 2: Add 1.74kg of diisopropyl peroxydicarbonate to the polymerization kettle, keep the reaction temperature at 170°C, and after 4 hours of polymerization, discharge the polymer in the polymerization kettle, filter and remove other impurities at a temperature above 100°C , which is acrylic acid maleic acid polyester.

[0062] Take 10kg of acrylic maleic acid polyester, 40kg of lauryl acetate, 40kg of butanediol oleate, and 7kg of vulcanized rapeseed oil in the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com