A catalyst for f-t synthesis of middle distillate isomerization depressant and its special core-shell structure composite molecular sieve

A middle distillate and composite molecular sieve technology, which is applied in the field of core-shell structure composite molecular sieves, can solve the problems of molecular sieve skeleton destruction, hydrothermal stability decline, and complex process conditions, and achieve high isomerization selectivity and selectivity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Prepare aluminum sulfate aqueous solution, KOH aqueous solution, silica sol aqueous solution and 1-ethylpyridinium bromide (SDA) aqueous solution respectively, and mix them to obtain ZSM-22 molecular sieve sol, crystallize at 180°C for 24h, cool, Suction filtration, washing, drying at 80°C for 24 hours, and calcination at 500°C for 8 hours to obtain ZSM-22 molecular sieve. Among them, the amount of aluminum sulfate is Al 2 o 3 In terms of KOH, the amount of K 2 In terms of O, the amount of silica sol is SiO 2 In total, the feed ratio (molar ratio) is as follows:

[0073] SiO 2 / Al 2 o 3 =100,K 2 O / SiO 2 =0.6,H 2 O / SiO 2 =30, SDA / SiO 2 = 0.2.

[0074] Take 2.0g of potassium hydroxide and add it to 50g of deionized water, weigh 8.0g of dodecyltrimethylammonium bromide and add it to the potassium hydroxide solution. After it is completely dissolved, weigh 10.0g of ZSM-22 molecular sieve and add it to the solution middle. After fully stirring for half an hour,...

Embodiment 2

[0077] Add 12.0 g of the ZSM-22 molecular sieve in Example 1 into 0.801 L of aqueous sodium hydroxide solution (1.5 mol / L), then weigh 10.8 g of cetyltrimethylammonium bromide and add it to the mixed solution, and stir thoroughly For half an hour, put it into a stainless steel crystallization kettle, and pre-crystallize at a constant temperature of 100°C for 8h. After cooling down, the mixed solution was taken out, and 3.2 g of sulfuric acid was added to adjust the pH value to 8.0 under the condition of rapid stirring. After fully mixing, put it into a stainless steel crystallization kettle again, and crystallize at a constant temperature of 80°C for 48h under dynamic conditions. Then washing, drying and calcining to obtain the composite molecular sieve with core-shell structure.

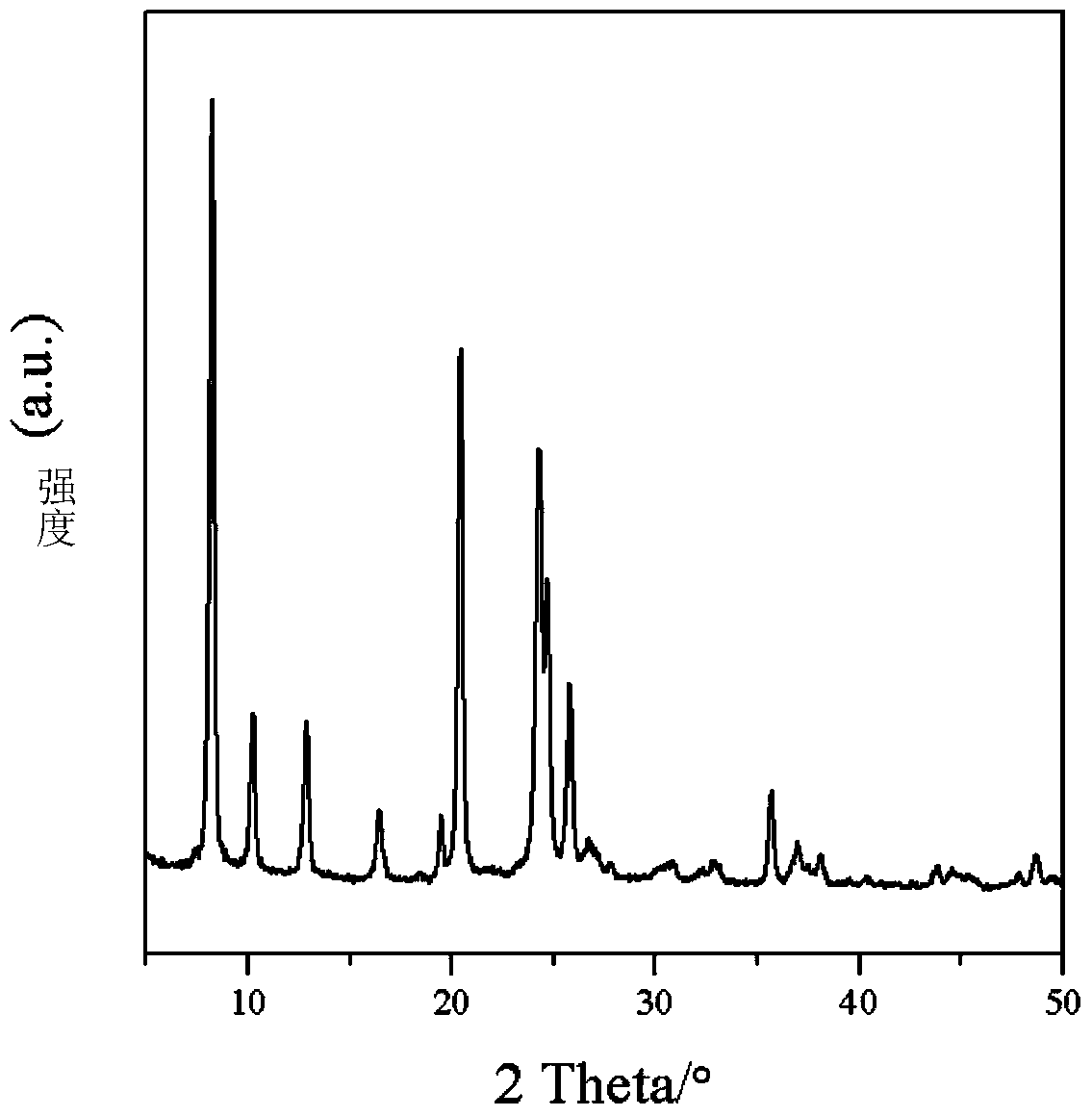

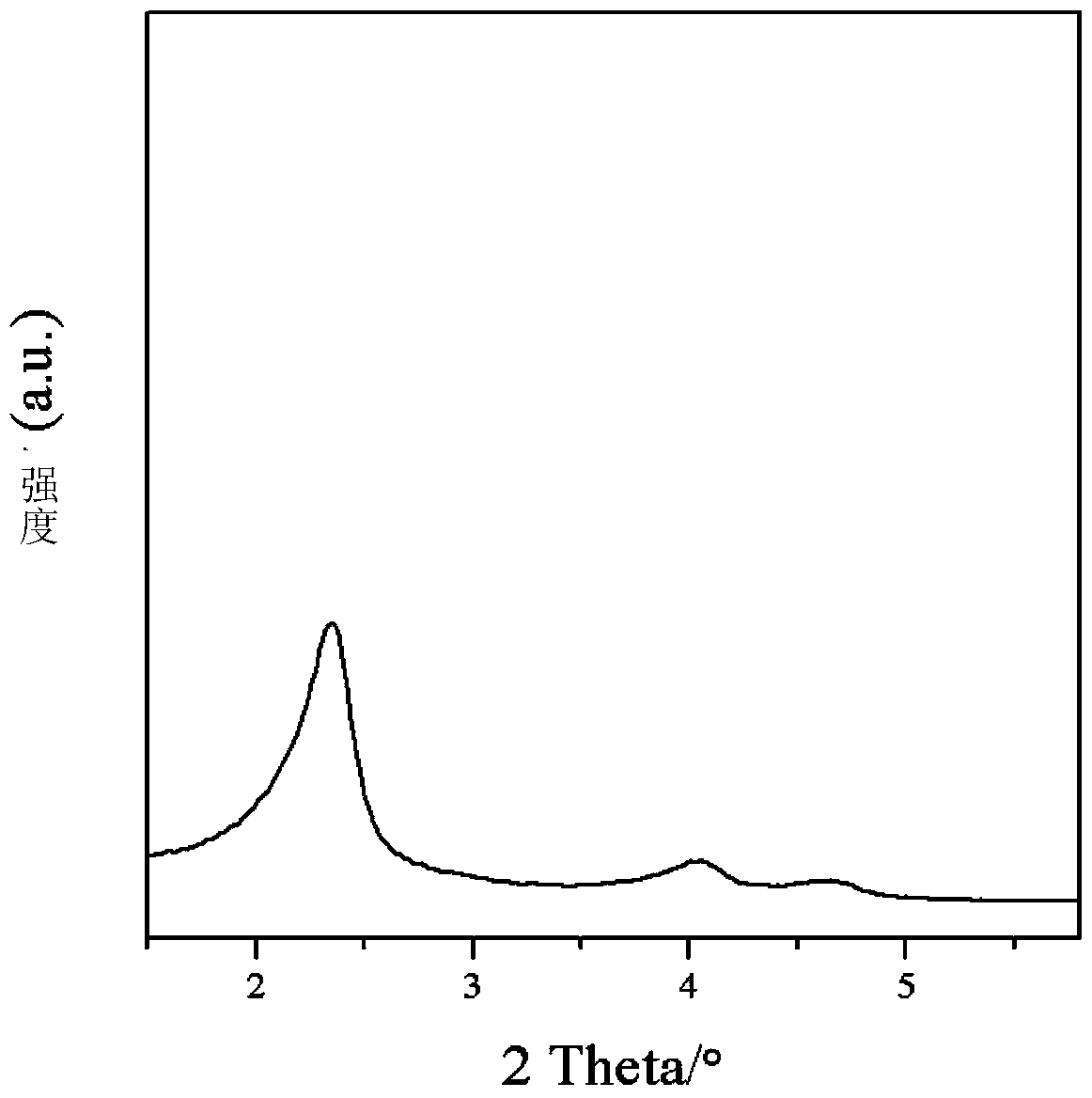

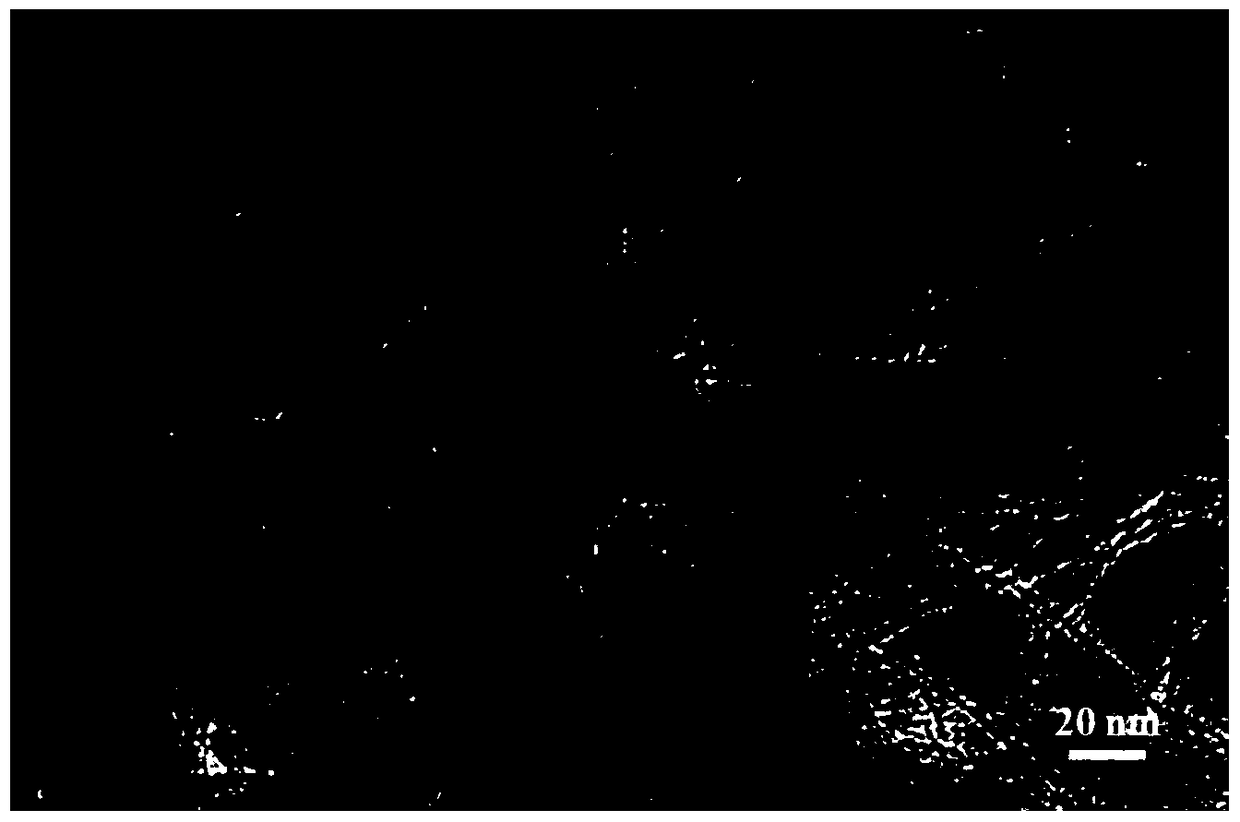

[0078] Take some samples for X-ray powder diffraction measurement, Figure 5 It is the wide-angle XRD pattern of the sample, and the result shows that there is ZSM-22 molecular sieve in the obtain...

Embodiment 3

[0080] Add 12.0 g of the ZSM-22 molecular sieve in Example 1 into 0.801 L of aqueous sodium hydroxide solution (1.5 mol / L), then weigh 18.1 g of hexadecyltrimethylammonium bromide and add it to the mixed solution, and stir thoroughly For half an hour, put it into a stainless steel crystallization kettle, and pre-crystallize at a constant temperature of 70°C for 40h. After cooling down, the mixed solution was taken out, and 2.1 g of sulfuric acid was added to adjust the pH value to 11.5 under the condition of rapid stirring. After fully mixing, put it into a stainless steel crystallization kettle again, and crystallize at a constant temperature of 100°C for 24h under dynamic conditions. Then washing, drying and calcining to obtain the composite molecular sieve with core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com